Well there goes my chances of 9s this year

- Thread starter Bbuchanan11

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

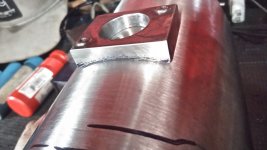

Been following this thread for over a year now , and seeing how no one seems to have the bad kinda luck Brendan has with this engine, I offered to make the Maf flange the "other guy" messed up. Being titanium, it's difficult to machine, especially drill and tap M4x.7 holes so they wouldn't even do that for him. Having a small machine shop at my house allows me to build one off parts like this for not only myself, but for other people as well. Call it a side hustle, but for me, I enjoy it as it not only makes a little money, but gets me out of the chaos of having 4 young children. Anyways, here's a few pictures of where I am at with it. Old school machining on a Bridgeport with all manual layout and reading off the dials. No CNC here. Only pieces of drop titanium we were able to find that would work were way oversized, but that allows me to make a mistake if necessary, like snap a tap off in the hole  . Actually surprised, this drilled/tapped smoothly and only have to machine away the excess and mill the radius. Enough of my jabbering now, more pics to follow tomorrow.

. Actually surprised, this drilled/tapped smoothly and only have to machine away the excess and mill the radius. Enough of my jabbering now, more pics to follow tomorrow.

Attachments

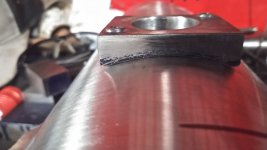

Heres a few more pics of the machining process. Not having a CNC, I had to get creative to make the two protruding areas that the sensor screws to. Using a 9/16" annular cutter I cut a .040" deep pocket centered on each screw hole then milled away the excess around it. A quick cut on the band saw and a few passes with a face mill and the bottom is now flat and parallel with the top. Last step is to cut the radius for the 5" tubing. Here's a few more pics. Will have this completed tomorrow and shipped back to Brendan.

Attachments

-

KIMG6230.JPG177.5 KB · Views: 17

KIMG6230.JPG177.5 KB · Views: 17 -

KIMG6231.JPG185.3 KB · Views: 17

KIMG6231.JPG185.3 KB · Views: 17 -

KIMG6232.JPG218.1 KB · Views: 16

KIMG6232.JPG218.1 KB · Views: 16 -

KIMG6234.JPG174.1 KB · Views: 15

KIMG6234.JPG174.1 KB · Views: 15 -

KIMG6237.JPG177.6 KB · Views: 15

KIMG6237.JPG177.6 KB · Views: 15 -

KIMG6240.JPG171 KB · Views: 13

KIMG6240.JPG171 KB · Views: 13 -

KIMG6239.JPG207.1 KB · Views: 15

KIMG6239.JPG207.1 KB · Views: 15 -

KIMG6238.JPG210.8 KB · Views: 14

KIMG6238.JPG210.8 KB · Views: 14 -

KIMG6228.JPG191.5 KB · Views: 21

KIMG6228.JPG191.5 KB · Views: 21

I hope it didn't sound like I insinuated that, his work looks top notch, I know who made it , just didn't want to name names.Just to clarify my buddy did not make the first one lol… it was a company that did it.

Funny though, a million dollar company with a half a million dollar water jet couldn't get it right the first time, but some hillbilly like me with a clapped out Bridgeport in his garage nailed it first shot...just sayinJust to clarify my buddy did not make the first one lol… it was a company that did it.

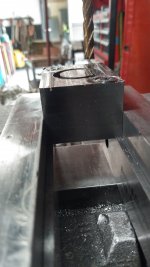

Here's the final fit on a piece of 5" tubing. Nice tight joints are imperative with thin wall titanium. I used a 5" drum sander with a 40 grit ceramic drum on the milling machine, then touched it up by hand with a 120 grit ceramic flap wheel. Will ship this out tomorrow morning. Can't wait to see what Brendan's welder does with the intake! Probably one of a handful of titanium intakes on a Duramax in the country! Way to be fancy Brendan!!!

. I'm just jealous you've got yours almost running and mines on a stand in the garage

. I'm just jealous you've got yours almost running and mines on a stand in the garage .

.

Attachments

Haha looks great John!… I’m excited to finally have it back in one piece… next month will be 2 years since it’s moved under its own power.

Mines been apart since this month last year, I couldn't imagine two! Won't be long now. Any progress on the wiring?Haha looks great John!… I’m excited to finally have it back in one piece… next month will be 2 years since it’s moved under its own power.

Looks great Brendan! Happy for you man, been a long time coming on this one! I bet it sounds KILLER! Fingers pistons have an awesome sound to them and I bet that turbo setup screams.View attachment 126022View attachment 126023Well got it running and took it for a ride finally… air intake is still being worked on so I can run an air filter…odss happens to be at my home town track this weekend… I’d love to go run 6.70 class so bad but it’s just too early to run it.

Thanks John! And it does sound totally different. I’ll have to take a video of it running and send it to you… not sure how to post videos on here. Had to fix I few simple leaks after letting sit for a few days. Did a hard 4wd rolling pull today and it definitely pulls way harder then it did before.

Awesome Brendan! Send me a video when you get time. Happy for ya brother.

Glad you got it running!!Thanks John! And it does sound totally different. I’ll have to take a video of it running and send it to you… not sure how to post videos on here. Had to fix I few simple leaks after letting sit for a few days. Did a hard 4wd rolling pull today and it definitely pulls way harder then it did before.

The easiest method is to upload it privately to YouTube where it is only viewable with the link, paste/imbed the link here and boom you're good to go!