Went to put in the c3's and I got stumped. I have different steels because I went with the pinwheels. Tried to call your cell Mike but the number on here didn't work. Sent Andrew a message but I don't think he saw so we called it quits for the night.

LBZ: Trans build prep

- Thread starter DaJokr

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I just wanna say unless you have access to a hoist and (at a minimum) air tools, it really sucks pulling it all out caveman style.

Had to call poor Mike today with what had to be the dumbest of questions. I bet he's just waiting for me to wreck it now lol. Sorry to have bugged ya Mike, I felt pretty silly.

No hoist but I do have a transmission jack, compressor, air tools and have made a PTO mount plate for my engine stand.

Ordered the Transmission Times from Suncoast last night.

Last edited:

Get the atsg as well. You need both, believe me. Make sure you have tall stands. I had my jack on a pair of 4x4's with another 4x4 maxed out and still had to use a dip in the asphalt to sneak the bell housing under the frame. I have to lift the truck higher tomorrow to get the tranny back underneath.

So, here's my problem. Hopefully Andrew sees this or Mike knows. With the pinwheels I have 5 steels, 3 thick and 2 thin. The original steels that come with the gmax kit according to the sheets are all the same. Is there a particular order or does it matter?

I was thinking friction;thick;friction;thin;friction;thick;friction;thin;friction;thick;friction

That sound ok?

I was thinking friction;thick;friction;thin;friction;thick;friction;thin;friction;thick;friction

That sound ok?

IIRC, the thicker steels are installed in the center for better heat dissipation. I would wait on Mike or Andrew to chime in as I have no experience with those specific clutches though.

IIRC, the thicker steels are installed in the center for better heat dissipation. I would wait on Mike or Andrew to chime in as I have no experience with those specific clutches though.

You remembered correctly.

So, here's my problem. Hopefully Andrew sees this or Mike knows. With the pinwheels I have 5 steels, 3 thick and 2 thin. The original steels that come with the gmax kit according to the sheets are all the same. Is there a particular order or does it matter?

I was thinking friction;thick;friction;thin;friction;thick;friction;thin;friction;thick;friction

That sound ok?

Stacking it out that way would be fine.

I heard from Andrew and he said to check with George in there shop there, so I think I'll just double check with him, but thanks for the insight as to why the thick ones should run in the middle of the stack.

I'm eager to get the c3's finished off as the input drum and pump are complete, so I'll be able to button the top up and flip the transmission to finish the back. Would be nice to at least get the transmission in the truck today.

I'm eager to get the c3's finished off as the input drum and pump are complete, so I'll be able to button the top up and flip the transmission to finish the back. Would be nice to at least get the transmission in the truck today.

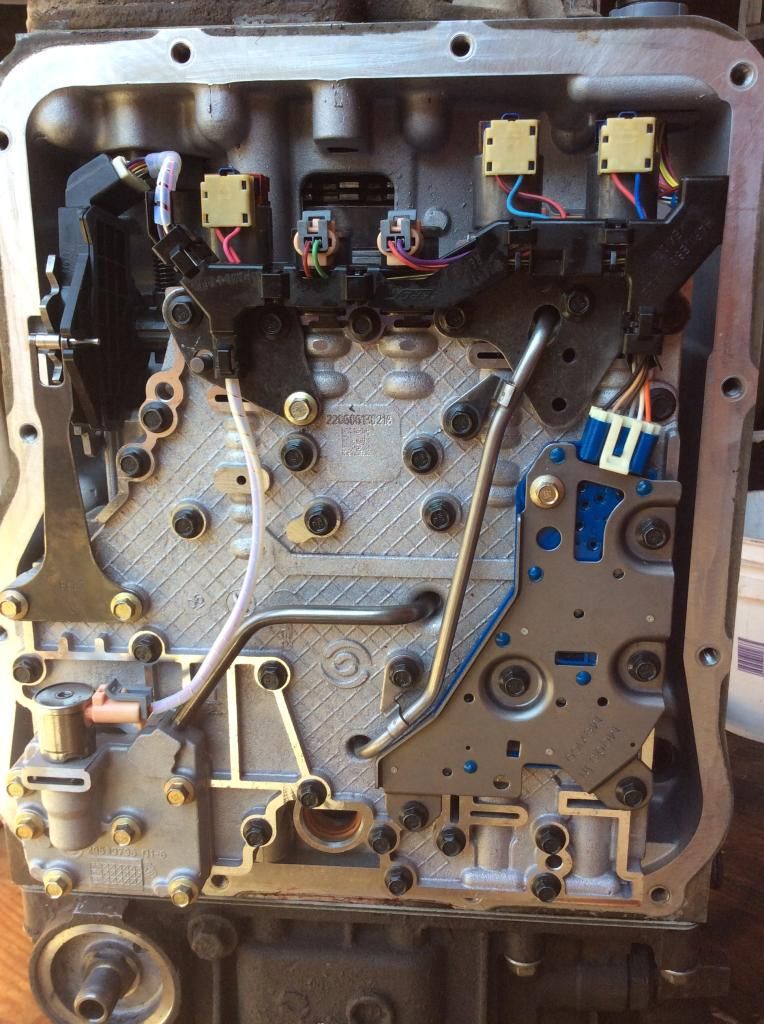

So the c4's had the same plate thicknesses as the c3's. 3 thick and 2 thin. Both sides we did thick in the middle. C3, input drum, pump, and bell housing are all installed and torqued down. C4's are in. Just have the planetary's to do befor the c5's go back and the tail housing is done. VB is stripped, cleaned, and almost finished reassembling. I was just going to leave I alone but some dirt fell on it when we opened the pan so I wanted to be safe. Looking like I may have it attatzched to the truck before the end of the day. Tommorow its hopefully all back together...and moving.

Get the atsg as well. You need both, believe me. Make sure you have tall stands. I had my jack on a pair of 4x4's with another 4x4 maxed out and still had to use a dip in the asphalt to sneak the bell housing under the frame. I have to lift the truck higher tomorrow to get the tranny back underneath.

Already have the ATSG first book I got. As far as getting the truck high enough I think mine is sitting on its tires if not I have four good ramps.

Back to reading all the post since I was here last. Good thread BTW.

Bang on Mike. Added fluid, codes deleted and stayed gone. It moves, no codes. Off to do the reprogramming.

Thanks Mike.

Thanks Mike.

Is there a break in time on the trans now? Or once its been reprogrammed can I start getting skinny happy and take it to the track?

Thanks everyone who offered advice and help. I just hope that the way I did my c3's and c4's doesn't come back to bite me in the ass. That's 2 phone calls I really wish I woulda made because other then that it was pretty straight forward.

Thanks everyone who offered advice and help. I just hope that the way I did my c3's and c4's doesn't come back to bite me in the ass. That's 2 phone calls I really wish I woulda made because other then that it was pretty straight forward.

Is there a break in time on the trans now? Or once its been reprogrammed can I start getting skinny happy and take it to the track?

Thanks everyone who offered advice and help. I just hope that the way I did my c3's and c4's doesn't come back to bite me in the ass. That's 2 phone calls I really wish I woulda made because other then that it was pretty straight forward.

Why would the way you did c3 and c4 come back to bite you in the ass?

Is there a break in time on the trans now? Or once its been reprogrammed can I start getting skinny happy and take it to the track?

Thanks everyone who offered advice and help. I just hope that the way I did my c3's and c4's doesn't come back to bite me in the ass. That's 2 phone calls I really wish I woulda made because other then that it was pretty straight forward.

Your TCM has not been programmed, it has been reset. The adaptive learns are now at base levels. ( drivable ) The learning starts now with a lot of stop and go driving. Start easy and get more aggressive as the shifts clear up. Do the same thing in T/H as it is on a different strategy.

Right on :thumb:,Glad to see you tackled it and all is good,Amazing what you can learn from all the fine folk,s on DD.

Right on :thumb:,Glad to see you tackled it and all is good,Amazing what you can learn from all the fine folk,s on DD.

...Not all good. I think I crushed the Torrington bearing when I put the extention housing in. It goes to the trans shop Wednesday. I'm hoping there is no damage to anything else. I heard what I can only presume was a crunch when I started to tighten the tail housing down though, and yes I didn't just crank them down, I worked them down slowly criss crossing to keep even pressure as it went down.

When I called Mike and explained it he said don't drive it, so it's getting towed to the shop to have my stupidity corrected.

If anyone reading this attempts there own build, I have only a few words of wisdom: DONT if your working in a set time frame. It takes longer then you think if you have no experience. RECHECK everything several times before you put snap rings or bolts or anything in. If it doesn't slide easy, don't force it. If it makes a sound that you don't like, disassemble to make sure no damage is incurred.

All in all, if I had rechecked the bearing when the extension housing went on by taking it off and making sure I didn't have something shift, and if I had kept rechecking fluid when I initially filled it, I'm pretty sure it would have been a problem free start.

It really makes your stomach sink when you spend a lot of time on something and it fails, especially when everyone thinks your stupid for even attempting it.

Not all trans builds are success stories. I wish this one was