Looks like Voodoo will be back in Ohio for a few months. I fired up Port engine yesterday, and she purrs like a kitten. As expected. Beside some nagging lift pump issues, it's been the finest piece of rotating steel parts I've ever had the pleasure of wrenching on. Just eats everything thrown at it, blows the chunks out the tail pipes, or valley,, and begs for more.. She did develop a slight lower pan drip right before I solved the blow by issues. Just annoying enough to leave a few black drops on the white bilge paint. So she getting yanked out, a nice warm bath, and maybe a bottom end inspection. I really hate to crack a bolt on that one, but we are approaching that 100hr mark when I wanted to check the wear indicators.

For Starboard engine, "problem child", I see a bit more disassembly in it's near future. Pulled all the glow plug hole fillers, and cranked it over yesterday. She blew a little coolant out of #4 or #6 holes. Spins over fast and free. No extra oil on the stick. So betting I didn't beat it up too badly. Just enough to hopefully expose the flaw to the naked eye.. Betting it's block related, so please keep eyes open for a GOOD LML donor will clean up at +0.020 bore.

What got problem child all worked up this last time, was getting the full 15klb load dumped on by her, by her twin sister at WOT.. First day at LOTO, right off the trailer, both engines were running 100%. Then when I turned the fuel/PW up, Port side lift pump started aerating the fuel again on the next run out. To verify that's what I was seeing, had to keep boat up on plane while I pulled up the pressure PID on the dash gauges. Running both at 3/4 throttle, but Stbd was doing all the work.. When I slowed down and opened the hatch, the 7psi cap in Stbd was venting pretty good.. While temp was only 210F, I knew she was pissed.

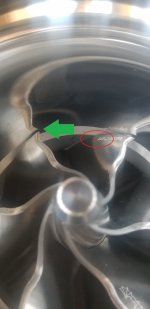

The pisser was, I had just replaced the Edelbrock, SX, PPE, 190GPH lift pump main body assembly on Stbd engine the day before for same reasons. These pumps did me well for many years, clear back to the OG PPE boat. With built in bypass and adjustable output pressure, no return lines, they fit marine diesel builds nicely. On this setup I have them pulling thru a 10m water separator, and pushing thru a NT 1m glass core directly below the outlet. Besides a couple motor bearing failures from water intrusion, they also seem to develop an internal leak in the pump body that is impossible to find. But they sure suck air,,, from somewhere after a few months time. Leading to air locks with no start situations.

Don't know what changed over past decade, but I do know Edelbrock states "Not For Diesel Fuel Use" right on the ads now. So they obviously know the answer. But with my good luck early on, I couldn't let that goofy manufacture warning deter me.. LOL.

Then after a half dozen trips to the dock on one engine, and last weekends last minute letdown, I'm calling them officially evicted from the bilge. Not sure what's going in place yet, but these pumps done and gone.. Last job was pumping 35gallons of fuel outa the boat and into my truck. Which let me capture the main issue for everyone to review.. A little air with your fuel??

Source: https://youtube.com/shorts/rHfBxhrnTZE?feature=share