Viberations at high speeds in 4wd with tuff country lift kit

- Thread starter ecc_33

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

for any driveline questions and custom shafts, deal with Alan Bick at Bick and Heintz Inc. in Utica, NY

A couple pics of the carnage

What shaft are you running now Sledheadxp800r?

Custom shaft? Still double cardan?

I dont trust mine anymore, I will fabricate a driveshaft safety loop soon, but there isnt much space with the double cardan

I just went back to the stock shaft. Actually Both my trucks are running stock front driveshafts without an issue.

There is a good chance the vibration is the U joints on the shaft. When at an angle, the U joint creates a movement in the driveshaft. The shaft must move forward and backward through out it's rotation. This causes a vibration at speed. A double cardan joint does not.

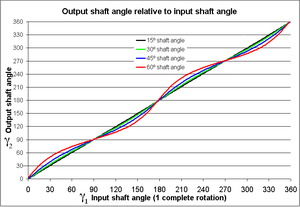

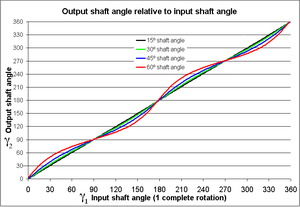

Here is a chart as well.

Here is a double cardan joint

The double cardan joint is in essence balenced, and does not change length through out it's movement.

However, as some have pointed out, the extra parts tend to make them more prone to breaking. My personal experice is different as the driveline angles I am forced to fight with are much more extreem on my Jeep. I have had great luck with driveshafts custom made by Tom Woods.

I don't have a great picture, but here is the best one I have...

And how about a show of stregnth... Was trying to climb some culverts, and the rear end had too much traction. I was in 4low, second gear on the red line, heard a pop. The components involved were the Tom Woods shaft, cromemolly D44 shafts, a rubicon carrier, and stock ring and pinion. I sheared the pinion off and broke the carrier.

Here is a chart as well.

Here is a double cardan joint

The double cardan joint is in essence balenced, and does not change length through out it's movement.

However, as some have pointed out, the extra parts tend to make them more prone to breaking. My personal experice is different as the driveline angles I am forced to fight with are much more extreem on my Jeep. I have had great luck with driveshafts custom made by Tom Woods.

I don't have a great picture, but here is the best one I have...

And how about a show of stregnth... Was trying to climb some culverts, and the rear end had too much traction. I was in 4low, second gear on the red line, heard a pop. The components involved were the Tom Woods shaft, cromemolly D44 shafts, a rubicon carrier, and stock ring and pinion. I sheared the pinion off and broke the carrier.

There is a good chance the vibration is the U joints on the shaft. When at an angle, the U joint creates a movement in the driveshaft. The shaft must move forward and backward through out it's rotation. This causes a vibration at speed. A double cardan joint does not.

only to a point at or above a certain degree does this backward and forward motion start to become so much that osilation starts and creates a vibration. if vibration happened at any slight angle, every HD out there would have vibration issues from the rear as they all use a single u-joint at the front and rear.

like i said before, the key issue is not the angle the driveshaft is put at. its the fact lift companys do not put the front diff pinion angle at a paralell angle to the t-case front output. this is why a double cardan works so well in our trucks. in that setup, you do not put any angle on the driveshaft where the single u-joint is, you let the double cardan take all the angle. if i didnt have to redesign my whole drop bracket from fabtech to change the pinion angle id do it so i could stop the vib without the addition of a double cardan driveshaft

only to a point at or above a certain degree does this backward and forward motion start to become so much that osilation starts and creates a vibration. if vibration happened at any slight angle, every HD out there would have vibration issues from the rear as they all use a single u-joint at the front and rear.

It does happen, only not enough for people to notice. The angle must reach a certain threshold to cause the vibration. It has to do with harmonics, some vibrations can be absorbed by the driveline, shocks, transfercase and transmission mount. Then you have the slip yolks that only feed the vibration to the axle. Easy to cover up. For an example, go look at early 2000's jeep liberty's, in 2wd model. There is, in essence, a dumbbell mounted to the front of the axle. That less than 1 degree on driveshaft that was less than 2 feet long was enough to cause a BAD harmonic vibration. They fixed it by adding weight to the front of the axle.

like i said before, the key issue is not the angle the driveshaft is put at. its the fact lift companys do not put the front diff pinion angle at a paralell angle to the t-case front output. this is why a double cardan works so well in our trucks. in that setup, you do not put any angle on the driveshaft where the single u-joint is, you let the double cardan take all the angle. if i didnt have to redesign my whole drop bracket from fabtech to change the pinion angle id do it so i could stop the vib without the addition of a double cardan driveshaft

There are other solutions as well. Running 2 double cardan joints would be your cheapest bet, and I think it would be the strongest.

Most lift companies don't change the pinion angle because that same angle will make matters even worse with different u joint angles. The other issue, it stems from how much work used to be involved in rotating the pinion angle on a front axle. I know 2 guys that I think could do it around me, and they don't own shops. That is a huge procedure that after people started lifting, they found they didn't feel like spending money on. The lift companied found they didn't have to change the pinion angles as no one seemed to care, and it saved money.

AHHH, U joints, the only discussion that tops religion. Everyone has their own viewpoint on it, and what they think is right. I don't know everything, I'm just trying to explain what I have come to know as fact.

So your telling me that's why I have a vibration at 50 mph? I have new tires and it still does it

It does happen, only not enough for people to notice. The angle must reach a certain threshold to cause the vibration.

There are other solutions as well. Running 2 double cardan joints would be your cheapest bet, and I think it would be the strongest.

Most lift companies don't change the pinion angle because that same angle will make matters even worse with different u joint angles. The other issue, it stems from how much work used to be involved in rotating the pinion angle on a front axle. I know 2 guys that I think could do it around me, and they don't own shops. That is a huge procedure that after people started lifting, they found they didn't feel like spending money on. The lift companied found they didn't have to change the pinion angles as no one seemed to care, and it saved money.

AHHH, U joints, the only discussion that tops religion. Everyone has their own viewpoint on it, and what they think is right. I don't know everything, I'm just trying to explain what I have come to know as fact.

Its not hard to make the pinion angle correct when factory can get it right off the get go. Its like you said, they took the cheap route and now created a market for double cardan driveshafts when they can be avoided to begin with

Lower the damn thing lol

After i lowered the front of my truck early this spring mine is for the most part gone.

A couple pics of the carnage

Thanks for warning me about this shaft! I think you saved me from bigger damage. I finished my driveshaft loop last Friday, went to the dragraces on Sunday, first run was fine, but when I was building boost at the line on my second run: boom

Will post some pics later...

damn you would think those parts are chinese. its awefully sad our stock driveshafts hold up better even with the bad angles on the u-joints.

what do you Guys think about this shaft?

http://www.ccidriveline.com/chevrolet/99-06-external-slip-cv-front-driveshaft.html

They address the problem that we are seeing on those shafts and made it stronger.

http://www.ccidriveline.com/chevrolet/99-06-external-slip-cv-front-driveshaft.html

They address the problem that we are seeing on those shafts and made it stronger.

IMOP, id source a dodge or ford CV and mate it to the stock shaft. one day ill get mine done that way. then its all stock parts you know wont give issues.

I'm bringing back an old thread. Has anyone found a cv style front driveshaft that has no vibration and that holds up to drag racing? Or is it safer just to run the stock style driveshaft with the vibrations?