ARP States you can use Loc-tite, You just need to put full torque on the studs before it sets up fully.Ok so now my next "best even torque technique" question has to be, 1/4 turn Loc-Tite vs lightly bottomed threads.

I'm just guessing here, but our primary goal is to allow all the studs to fully float evenly thru heat and pressure cycles. Which bottomed they likely do not. So using Loc-Tite actually allows for heat expansion, without allowing rotation? Am I close?

Or is our goal just to hold em even long enough to get everything torqued down? Curious, because that is moving away from the lightly lubricated threads belief of no drag on the fastener equals truer values.

Twins with Twins, Anyone?

- Thread starter kidturbo

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Attachments

I think we are getting our wires crossed. Loc-Tite ONLY on the block side. It does NOTHING to affect torque other than keeping the stud from rotating.Ok so now my next "best even torque technique" question has to be, 1/4 turn Loc-Tite vs lightly bottomed threads.

I'm just guessing here, but our primary goal is to allow all the studs to fully float evenly thru heat and pressure cycles. Which bottomed they likely do not. So using Loc-Tite actually allows for heat expansion, without allowing rotation? Am I close?

Or is our goal just to hold em even long enough to get everything torqued down? Curious, because that is moving away from the lightly lubricated threads belief of no drag on the fastener equals truer values.

I’m reminded of something the late Mike Lovrich said once, “use blue loctite on things you want to take apart often, red on things you don’t!”. Seems like this might apply here…….

Or you could use the orange which is said to be as strong as red but removable like blue.I’m reminded of something the late Mike Lovrich said once, “use blue loctite on things you want to take apart often, red on things you don’t!”. Seems like this might apply here…….

Sent from my Pixel 5 using Tapatalk

I've always felt like the feeling you get of the stud getting loose while torquing was from the washer spinning against the head and creating a second area of slip which reduces the friction acting against the nut. I've read conflicting information about using the ARP lube on both sides of the washer to promote this double slip action, and I've read that you should clean the head surface of any oil and lightly sand the bottom of the washer to prevent it from spinning. I'm not totally sure what the correct answer is to be honest.

Here's an article a quick google search turned up: https://www.enginelabs.com/engine-t...-avoid-pulling-threads-or-killing-head-bolts/

Here's an article a quick google search turned up: https://www.enginelabs.com/engine-t...-avoid-pulling-threads-or-killing-head-bolts/

In some of the ARP Kits, They now include what they are calling a stamped washer. It puts a texture on 1 side to keep it from slipping. They also revised the Final Torque Value if you get a newer kit with those washers. Same part number different final torques based on the washer. This happens to be for LS applications. Not sure which other sets changed.I've always felt like the feeling you get of the stud getting loose while torquing was from the washer spinning against the head and creating a second area of slip which reduces the friction acting against the nut. I've read conflicting information about using the ARP lube on both sides of the washer to promote this double slip action, and I've read that you should clean the head surface of any oil and lightly sand the bottom of the washer to prevent it from spinning. I'm not totally sure what the correct answer is to be honest.

Here's an article a quick google search turned up: https://www.enginelabs.com/engine-t...-avoid-pulling-threads-or-killing-head-bolts/

Having done one recently, I still had one slip. I believe its because I do use ARP lube on the block side of the stud. But I have had and seen other people not use it and the studs tend to want to gal up. Even the Factory uses Loctite on the head bolts in that application and it still acts as a lubricant as well as a sealant.

That's actually what I asking. Let me rephrase. Is the goal of using Loc-Tite on block side of a stud to keep the stud from spinning down and bottoming out when torquing, or to actually keep if from rotating after torquing?I think we are getting our wires crossed. Loc-Tite ONLY on the block side. It does NOTHING to affect torque other than keeping the stud from rotating.

Goes back to that bottomed out stud threads vs backed out 1/4 turn starting point theory. 30yrs ago when I did a lot of studded stuff on SBC and SBF, always followed the lightly lube the block side, gracelessly moly lube both side of washers and top threads. Just wondering if data out there shows an advantage, or that studs can back off... As stated above, OEM's seem to be using Loc-Tite on the factory head bolts nowadays. Just wondig what I've missed being a keyboard tech.. lol

Last edited:

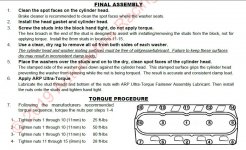

IE: From that ARP doc.

NOTE: LOCTITE MAY BE USED IF A PERMANENT MOUNTING OF THE STUDS IS PREFERRED. THE

FASTENERS, HOWEVER, MUST BE TORQUED PRIOR TO THE LOCTITE SETTING UP.

The goal is to NOT bottom out the studs. That only puts additional stress on the threads in the block and does nothing to hold down the head.That's actually what I asking. Let me rephrase. Is the goal of using Loc-Tite on block side of a stud to keep the stud from spinning down and bottoming out when torquing, or to actually keep if from rotating after torquing?

Goes back to that bottomed out stud threads vs backed out 1/4 turn starting point theory. 30yrs ago when I did a lot of studded stuff on SBC and SBF, always followed the lightly lube the block side, gracelessly moly lube both side of washers and top threads. Just wondering if data out there shows an advantage, or that studs can back off... As stated above, OEM's seem to be using Loc-Tite on the factory head bolts nowadays. Just wondig what I've missed being a keyboard tech.. lol

The whole thing about lube the nuts, with what and which washers to use goes away when you go to bolt stretch instead of torque.

I've never done the bolt stretch method, but I agree that's the most accurate way to torque. I'm not sure how you do that while you have a torque wrench and socket covering the end of the stud though.The goal is to NOT bottom out the studs. That only puts additional stress on the threads in the block and does nothing to hold down the head.

The whole thing about lube the nuts, with what and which washers to use goes away when you go to bolt stretch instead of torque.

na ive marked them and seen the studs turn from original location. if i threaded the stud all the way in, i never got the looseness feel when torquing.I've always felt like the feeling you get of the stud getting loose while torquing was from the washer spinning against the head and creating a second area of slip which reduces the friction acting against the nut. I've read conflicting information about using the ARP lube on both sides of the washer to promote this double slip action, and I've read that you should clean the head surface of any oil and lightly sand the bottom of the washer to prevent it from spinning. I'm not totally sure what the correct answer is to be honest.

Here's an article a quick google search turned up: https://www.enginelabs.com/engine-t...-avoid-pulling-threads-or-killing-head-bolts/

I've always bottom tapped all holes then ran the studs down with a 1/4" electric ratchet on the lowest setting. I've only ever gotten the "loose" feeling when the washer slipped.

You guys are actually reusing parts? Usually when I take something apart it’s been blown to pieces

And the key take away from this discussion goes to...You guys are actually reusing parts? Usually when I take something apart it’s been blown to pieces

And this is where a lot of builders say it's better to bottom them out. I see not much has changed while I stepped away for three decades. Last loose felling I got, was on those injector hold down studs mistakenly marked for 50ftlb torque..na ive marked them and seen the studs turn from original location. if i threaded the stud all the way in, i never got the looseness feel when torquing.

Interesting discussion none the less. Thanks for the input guys. And after checking the deck and heads, most likely point of failure goes back to Jon's first statement of that head got hot..

Doesn't explain why it let go that first time on the Dyno. She wasn't hot, just fully boosted. But it had LML gaskets. Time # 2, the first set of heads were planed on a belt sander, and surface texture showed it. However, original heads are still on the other engine running happy as can be, from same shop.. Heads we pulled off this engine 3yrs back thinking they were cracked, on a daily driver today. So I'm trying to cover all the bases and figure what the heck I missed.. Last time I missed something seriously wrong 2 times, I joined this forum... LOL

Maybe time to look into the PPE iron heads unless you think it was a fluke? Wondering if they might provide better heat handling characteristics than the OEM aluminum heads for how these engines will get used.And this is where a lot of builders say it's better to bottom them out. I see not much has changed while I stepped away for three decades. Last loose felling I got, was on those injector hold down studs mistakenly marked for 50ftlb torque..

Interesting discussion none the less. Thanks for the input guys. And after checking the deck and heads, most likely point of failure goes back to Jon's first statement of that head got hot..

Doesn't explain why it let go that first time on the Dyno. She wasn't hot, just fully boosted. But it had LML gaskets. Time # 2, the first set of heads were planed on a belt sander, and surface texture showed it. However, original heads are still on the other engine running happy as can be, from same shop.. Heads we pulled off this engine 3yrs back thinking they were cracked, on a daily driver today. So I'm trying to cover all the bases and figure what the heck I missed.. Last time I missed something seriously wrong 2 times, I joined this forum... LOL

caveat to this, i blew a chunk of my LB7 block out right up next to the lifter valley as i was torquing new heads onto the block on the final 150ft lbs cycle. it blew the threaded portion of the block right into there. The problem is, even though i bottom tapped and blew the holes out, i cant say for sure i didnt miss one hole with the tap or blow gun. Fish was helping me and that whole "bull shitting while you work" might have got me. what i do know is, each stud was threaded by hand till bottomed, then i gave a slight turn with the allen wrench like i normally do. i dont remember any stud giving a false bottoming out but again, talking while working. Fish was also the one doing the final torque sequence on the studs and i was teaching him how to not snap torque the studs but pull at an even slow rate till it clicked. I know that was correct.na ive marked them and seen the studs turn from original location. if i threaded the stud all the way in, i never got the looseness feel when torquing.

by that point, that block had a bunch of torque cycles through it between factory studs and the A1 studs. probably 6 or 7 cycles. So i dont know if there was something in the bottom of the hole, the bottomed out stud found a weak point in the block and put undue pressure into the side or if it was just going to happen regardless.

i really like fingers loctite deal, i think i would have had a higher chance of saving my block had i done that.

And look where that got you...Last time I missed something seriously wrong 2 times, I joined this forum... LOL

I do have a question for you though, Do you ever lap the deck surface?