Hey again guys and gals. I'm getting some questions as to how the stock intake manifold compares to the Banks Big Hoss manifold. I could go on and on about the details but I figured that a picture is worth a thousand words so here's the comparison (if you can really call it that). I do need to point out here that these are for hardcore engine builds ONLY. This is for you guys wanting 1000hp+ without having to run 100psi of boost. This isn't something you can bolt on in an hour for your daily driver. These parts are straight off our drag race/road race trucks.

Ok, here are some shots of the stock intake manifold as it sits on the truck. This is where the boost tube connects coming out of the intercooler:

All of the air has to pass through the above assembly just to reach the cylinder heads. But trust me it gets worse. After the air gets to the inlet tube the first restriction it reaches is this one:

This is the inlet tube that attaches to the intake "bridge that connects the two halfs of the engine together. You can plainly see the extremly sharp bend (almost 90 degrees) and below you can see the very sharp diameter change:

It's also not very large to begin with:

After that the air reaches the "bridge" where it runs straight into a wall:

But it still gets worse. Here a side shot if the inside of the intake "bridge" What your seeing here is the flange inside the bridge that supports the intake tube. The air actually has to make a 180 degree turn just to get around it. It's almost like the incoming air has to stop and ask for directions:

But still, it gets worse!! Here's a shot of the chamber where it attaches to the head. It also begs the question "How expensive can a bolt be?" The answer is "It depends on weather or not it falls out". If you look inside the opening, lower right corner, you can see one of the bolts that holds the chamber on. It's actually inside the chamber. You can also see that where the bridge meets the chamber the air runs into yet ANOTHER wall:

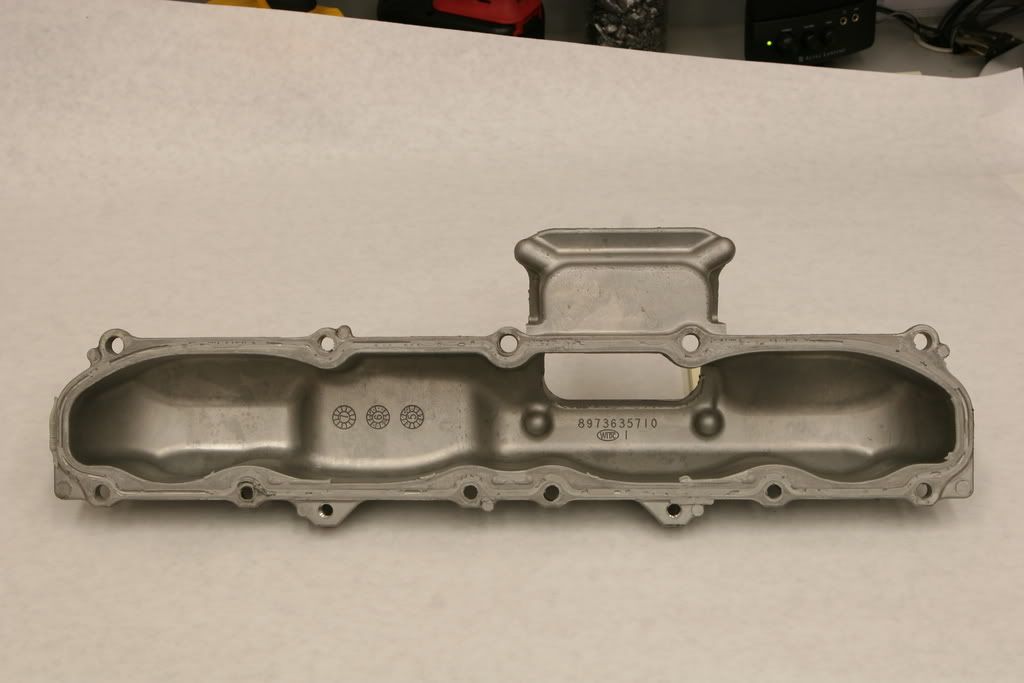

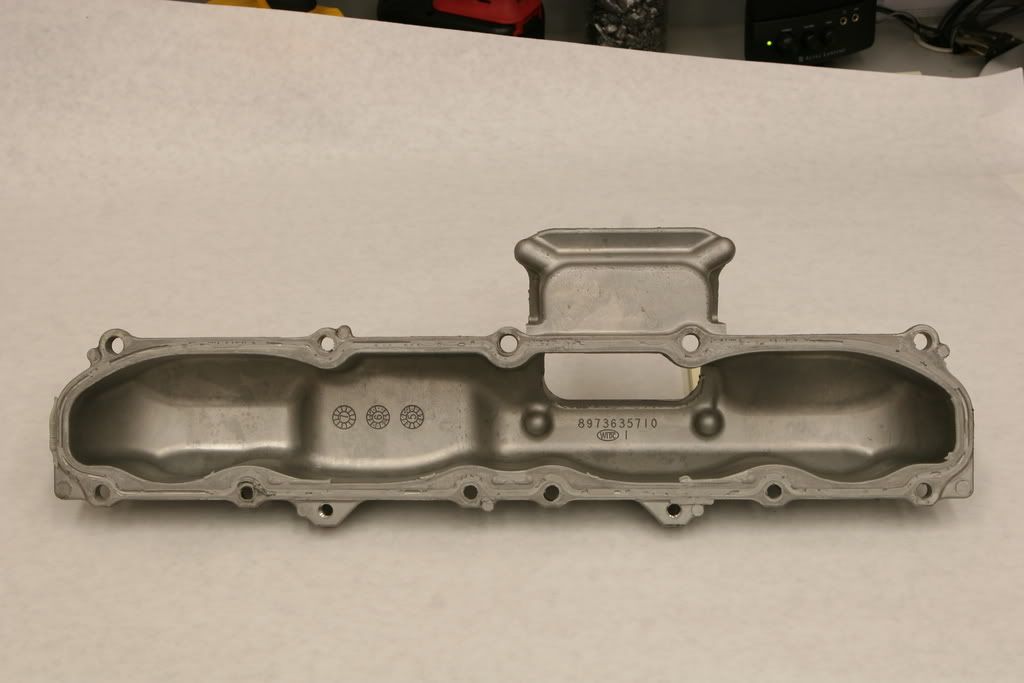

Here's a shot of the inside. Both chambers are totally different shapes which will greatly cut down the air delivery to the ports. You can also plainly see how small the stock intake chamber port actually is. Remember that the Duramax engine has 2 ports per cylinder and all 8 ports have to get their air through this little thing:

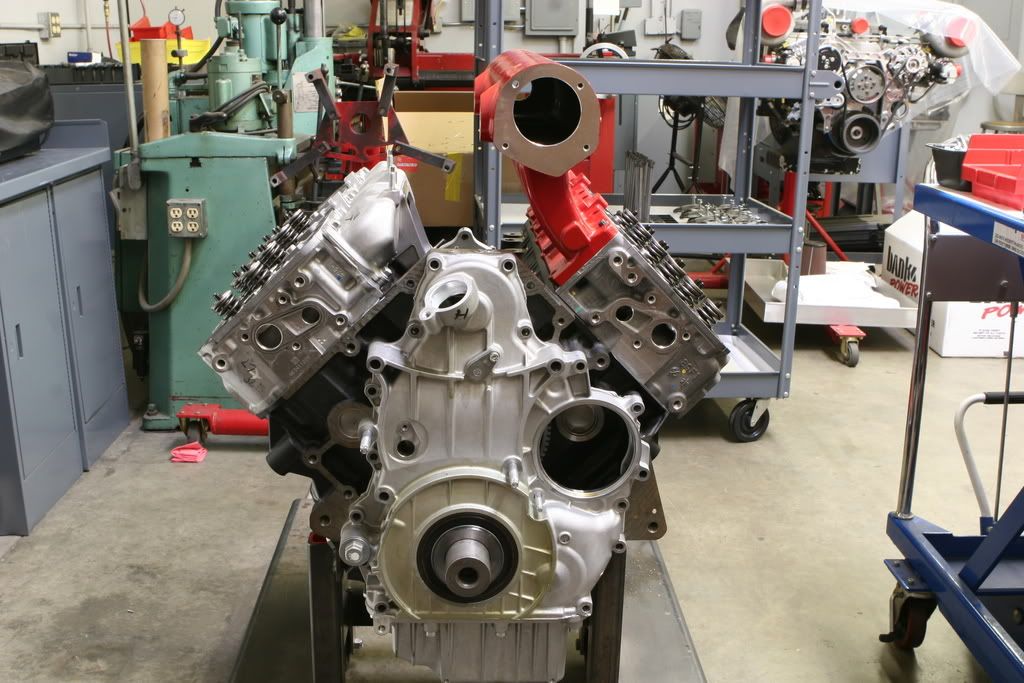

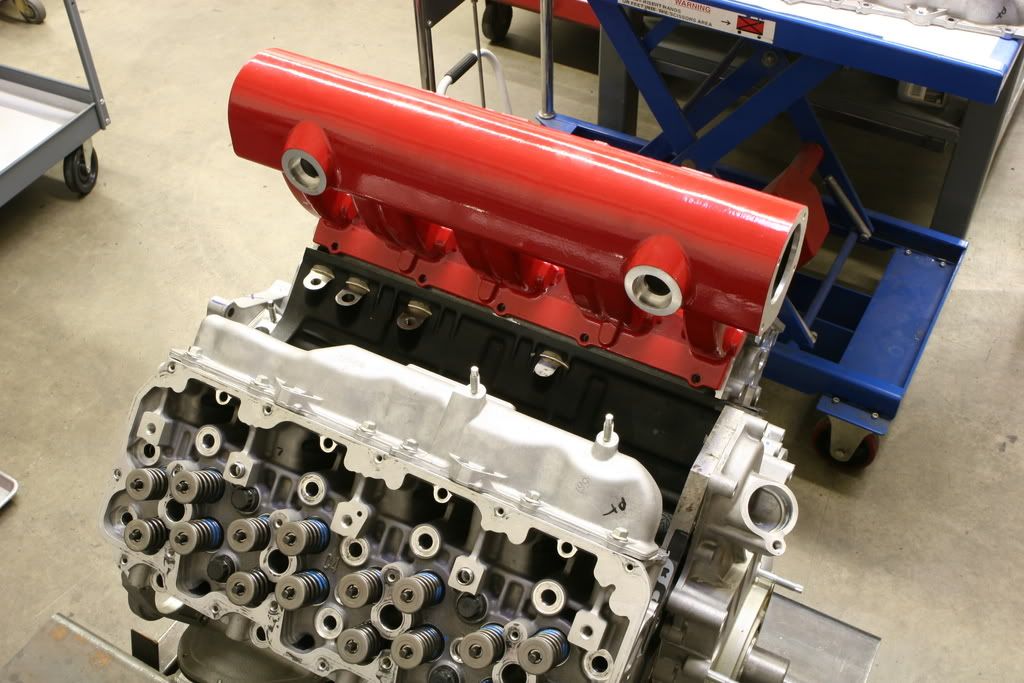

The Banks solution? Get rid of all of it:

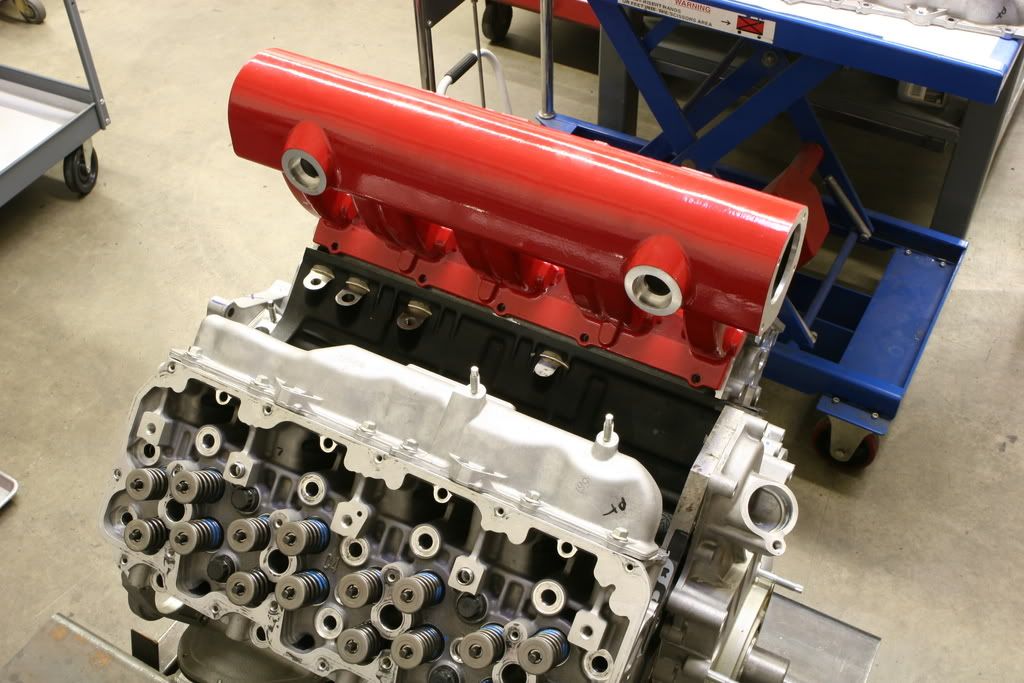

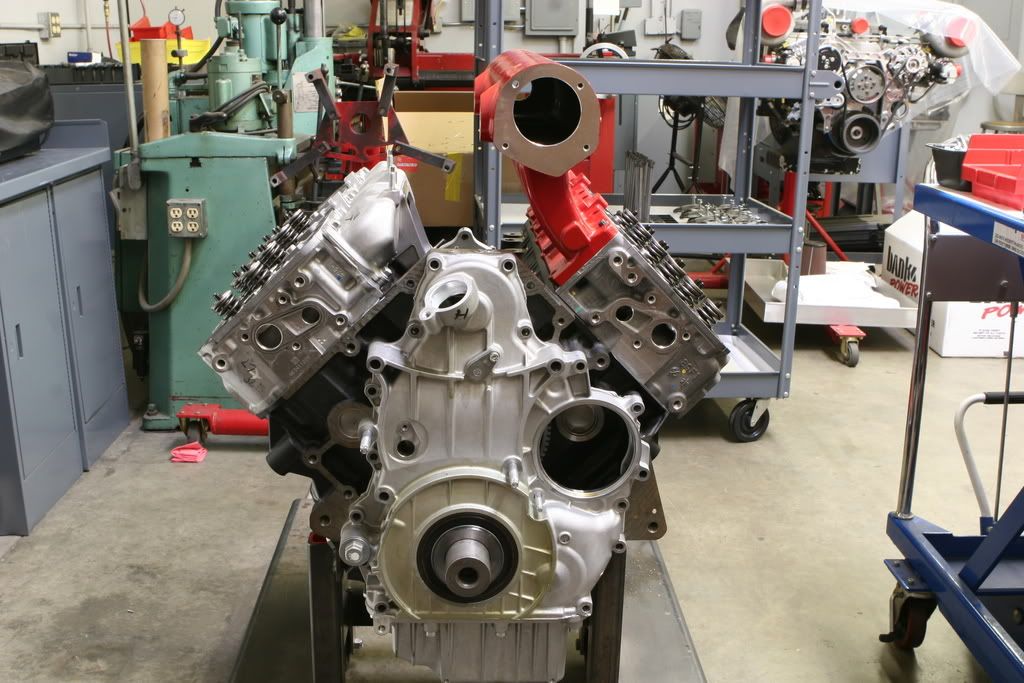

1/2 Banks 1/2 stock on the engine:

This manifold does away with ALL of the factory short comings. It has individual intake runners (2 per cylinder), a much larger intake area, very smooth transitions from the chamber to the port, they're o-ring sealed, and has a drasticly higher flow rate over stock. This design will allow you to deliver far higher volumes of air to your cylinder heads (and take better advantage of your port work) without having to run sky high boost pressures. Hope this helps

Ok, here are some shots of the stock intake manifold as it sits on the truck. This is where the boost tube connects coming out of the intercooler:

All of the air has to pass through the above assembly just to reach the cylinder heads. But trust me it gets worse. After the air gets to the inlet tube the first restriction it reaches is this one:

This is the inlet tube that attaches to the intake "bridge that connects the two halfs of the engine together. You can plainly see the extremly sharp bend (almost 90 degrees) and below you can see the very sharp diameter change:

It's also not very large to begin with:

After that the air reaches the "bridge" where it runs straight into a wall:

But it still gets worse. Here a side shot if the inside of the intake "bridge" What your seeing here is the flange inside the bridge that supports the intake tube. The air actually has to make a 180 degree turn just to get around it. It's almost like the incoming air has to stop and ask for directions:

But still, it gets worse!! Here's a shot of the chamber where it attaches to the head. It also begs the question "How expensive can a bolt be?" The answer is "It depends on weather or not it falls out". If you look inside the opening, lower right corner, you can see one of the bolts that holds the chamber on. It's actually inside the chamber. You can also see that where the bridge meets the chamber the air runs into yet ANOTHER wall:

Here's a shot of the inside. Both chambers are totally different shapes which will greatly cut down the air delivery to the ports. You can also plainly see how small the stock intake chamber port actually is. Remember that the Duramax engine has 2 ports per cylinder and all 8 ports have to get their air through this little thing:

The Banks solution? Get rid of all of it:

1/2 Banks 1/2 stock on the engine:

This manifold does away with ALL of the factory short comings. It has individual intake runners (2 per cylinder), a much larger intake area, very smooth transitions from the chamber to the port, they're o-ring sealed, and has a drasticly higher flow rate over stock. This design will allow you to deliver far higher volumes of air to your cylinder heads (and take better advantage of your port work) without having to run sky high boost pressures. Hope this helps

Last edited: