Info: Quad Turbo Update

- Thread starter FORBIDN

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2 words pretty much sum that truck up.

Holy sh!t :thumb:

I was thinking more like 3 words.

HOLY FU%$ING SHIT!!!!

Last edited:

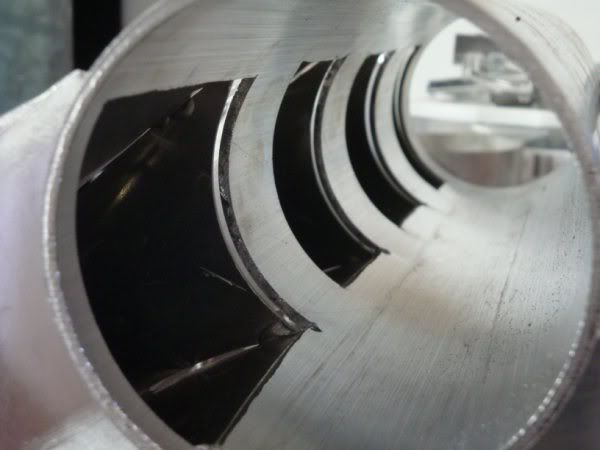

twin inlet twin outlet cooler! i cant add anymore pictures I maxed out my attachments.

Email your pics to a mod, they will post for you. Man I am staring and my mouth dried out and I think I dislocated my jaw. That is some AWESOME work, and a great paint job.

To you and whomever else is helping this along, you guys have put together one nice piece. Absolutely AMAZING. Someone pass me a beer and a sling so I can get my mouth closed.:thumb:

Moderator

Thanks......the paint was done by a guy here in billings,Montana as for the rest of the truck I am engineering and fabricating all of it myself.Do you have a moderator in mind that I can email those pics too.

Email your pics to a mod, they will post for you. Man I am staring and my mouth dried out and I think I dislocated my jaw. That is some AWESOME work, and a great paint job.

To you and whomever else is helping this along, you guys have put together one nice piece. Absolutely AMAZING. Someone pass me a beer and a sling so I can get my mouth closed.:thumb:

Thanks......the paint was done by a guy here in billings,Montana as for the rest of the truck I am engineering and fabricating all of it myself.Do you have a moderator in mind that I can email those pics too.

Thanks......the paint was done by a guy here in billings,Montana as for the rest of the truck I am engineering and fabricating all of it myself.Do you have a moderator in mind that I can email those pics too.

email them to me and i will be able to post them

Way cool. I want one. Don't know how much time you have in it, but I am guessing a year or so of full time based on the amount of custom fab work.

Now for the engineering that I know about:

From what I remember about fluid dynamics in school, you may want to radius the leading edges on intake runners. You will get excessive turbulant flow at the interface between the main supply tube and the downtubes. Could probably cost you about 20% or more in flow. Also the end runner tube will experience more flow and pressure:screwy:. If you do not believe me, look at a yard sprinkler. The old style ones with the curved water bar, the last hole is smaller than the previous and that one is smaller than the previous and such. Not all are smaller than the previous.

I do believe that it will work, just think that the balance may be off b/c of air flow rate. You may want to add pressure ports to the bottom of the intake runners to monitor the boost pressure until you get it tuned opcorn:.

opcorn:.

Now for the engineering that I know about:

From what I remember about fluid dynamics in school, you may want to radius the leading edges on intake runners. You will get excessive turbulant flow at the interface between the main supply tube and the downtubes. Could probably cost you about 20% or more in flow. Also the end runner tube will experience more flow and pressure:screwy:. If you do not believe me, look at a yard sprinkler. The old style ones with the curved water bar, the last hole is smaller than the previous and that one is smaller than the previous and such. Not all are smaller than the previous.

I do believe that it will work, just think that the balance may be off b/c of air flow rate. You may want to add pressure ports to the bottom of the intake runners to monitor the boost pressure until you get it tuned

Way cool. I want one. Don't know how much time you have in it, but I am guessing a year or so of full time based on the amount of custom fab work.

Now for the engineering that I know about:

From what I remember about fluid dynamics in school, you may want to radius the leading edges on intake runners. You will get excessive turbulant flow at the interface between the main supply tube and the downtubes. Could probably cost you about 20% or more in flow. Also the end runner tube will experience more flow and pressure:screwy:. If you do not believe me, look at a yard sprinkler. The old style ones with the curved water bar, the last hole is smaller than the previous and that one is smaller than the previous and such. Not all are smaller than the previous.

I do believe that it will work, just think that the balance may be off b/c of air flow rate. You may want to add pressure ports to the bottom of the intake runners to monitor the boost pressure until you get it tunedopcorn:.

But in an irrigation system the valves are all open. And there is always flow going through them. A engine has valves opening and closing. I'm not trying to be a Albert Einstein or anything of the sorts but wouldn't those two scenarios be completly different. I have not seen a Banks intake manifold in person but I think their intake runners are all the same size.

http://assets.bankspower.com/prod_images/1098/BigHossIntake-Dmax.jpg

It looks like the last intake runner is about half the size of the others for some strange reason.

I agree with the valves opening and closing. I would need to look at the valve map to see where each opens and its duration. I can imagine that there should be a steady flow of air through the valves. Otherwise there would be pulsing and a lot of blow off due to overpressure.

It looks like the last intake runner is about half the size of the others for some strange reason.

I agree with the valves opening and closing. I would need to look at the valve map to see where each opens and its duration. I can imagine that there should be a steady flow of air through the valves. Otherwise there would be pulsing and a lot of blow off due to overpressure.

http://assets.bankspower.com/prod_images/1098/BigHossIntake-Dmax.jpg

It looks like the last intake runner is about half the size of the others for some strange reason.

I agree with the valves opening and closing. I would need to look at the valve map to see where each opens and its duration. I can imagine that there should be a steady flow of air through the valves. Otherwise there would be pulsing and a lot of blow off due to overpressure.

They all look to be the same size to me. Hell forbidn's looks to be pretty close to the same design. And I'm not trying to be an azzhole but I think you are trying to overthink this. Pressure is pressure.

Intake manifold Design

I do believe you are correct in the fact that the air will hit the back of the plenum and force the air into the last intake port. That is a fact! but thats why I have built them 2 inches longer than the last port........rather than acting like a slide where the the air hits the back of the plenum and has an easy way into the last intake port....being that it is longer when the air hits the back wall of the plenum it will create reversion and for the most part equilize the incoming air. I also agree with radiusing the inner edges of the intake tubes.......I just havent got that far yet!

http://assets.bankspower.com/prod_images/1098/BigHossIntake-Dmax.jpg

It looks like the last intake runner is about half the size of the others for some strange reason.

I agree with the valves opening and closing. I would need to look at the valve map to see where each opens and its duration. I can imagine that there should be a steady flow of air through the valves. Otherwise there would be pulsing and a lot of blow off due to overpressure.

I do believe you are correct in the fact that the air will hit the back of the plenum and force the air into the last intake port. That is a fact! but thats why I have built them 2 inches longer than the last port........rather than acting like a slide where the the air hits the back of the plenum and has an easy way into the last intake port....being that it is longer when the air hits the back wall of the plenum it will create reversion and for the most part equilize the incoming air. I also agree with radiusing the inner edges of the intake tubes.......I just havent got that far yet!