I know there have been some threads about this shop already but wanted to further warn people that are looking to have their transmission built or buy a complete transmission. I had a customer that gave me a deposit on a trans build but then "couldn't afford" to have his transmission built by me, so he picked up his SunCoast GMax-6-3 kit and Precision Industries converter from me and had it all installed in his LMM by Per4mance Innovations. After the break in period he brought the truck back to me to have his tuning upgraded to all out race tuning I told him things didn't feel right - some shifts were harsh, some flared horribly, downshifts felt like you were getting rear-ended. He drove it anyway and in less than a month was limping the built transmission. He had an intake, exhaust, lift pump, shimmed FPRV, and tuning on an otherwise stock LMM and was running tuning that has dynoed 550+ rwhp on LMMs with similar mods. As time went on it got worse and worse and the owner of Per4mance Innovations stopped answering his phone calls and wouldn't correct the transmission issues, so he broke down and brought it to me to clean up their mess. Upon teardown I found the following discrepancies:

Here are pictures of the torn C3 apply piston and separator plate:

Just the labor here brought him up to what it would have cost him to have me build it right (and stand behind it). Then tack on the parts that had to be replaced (C3 apply piston, C3 clutches, separator plate), machining to get proper clearance, fluids, filters, and his bill at Per4mance Innovations and he is way over the price he "couldn't afford" in the first place. Moral of the story is that if you can't afford to have it done right the first time by a shop that knows what they are doing and stands behind their work, will you be able to afford to have it fixed?

- C4 clearances were over .030" too loose (looser than the top of the range that SunCoast recommends).

- C3 apply piston was torn during installation and applying the C3 clutched crooked and not fully applying them

- C3 clutches were all warped from being improperly applied

- C2 clearances were over .015" too loose

- C1 clearances were over .025" too loose

- Main pressure regulator spring wasn't properly shimmed - builder had replaced the correct .136" shim with an improperly fitting .102" shim, meaning lower line pressure

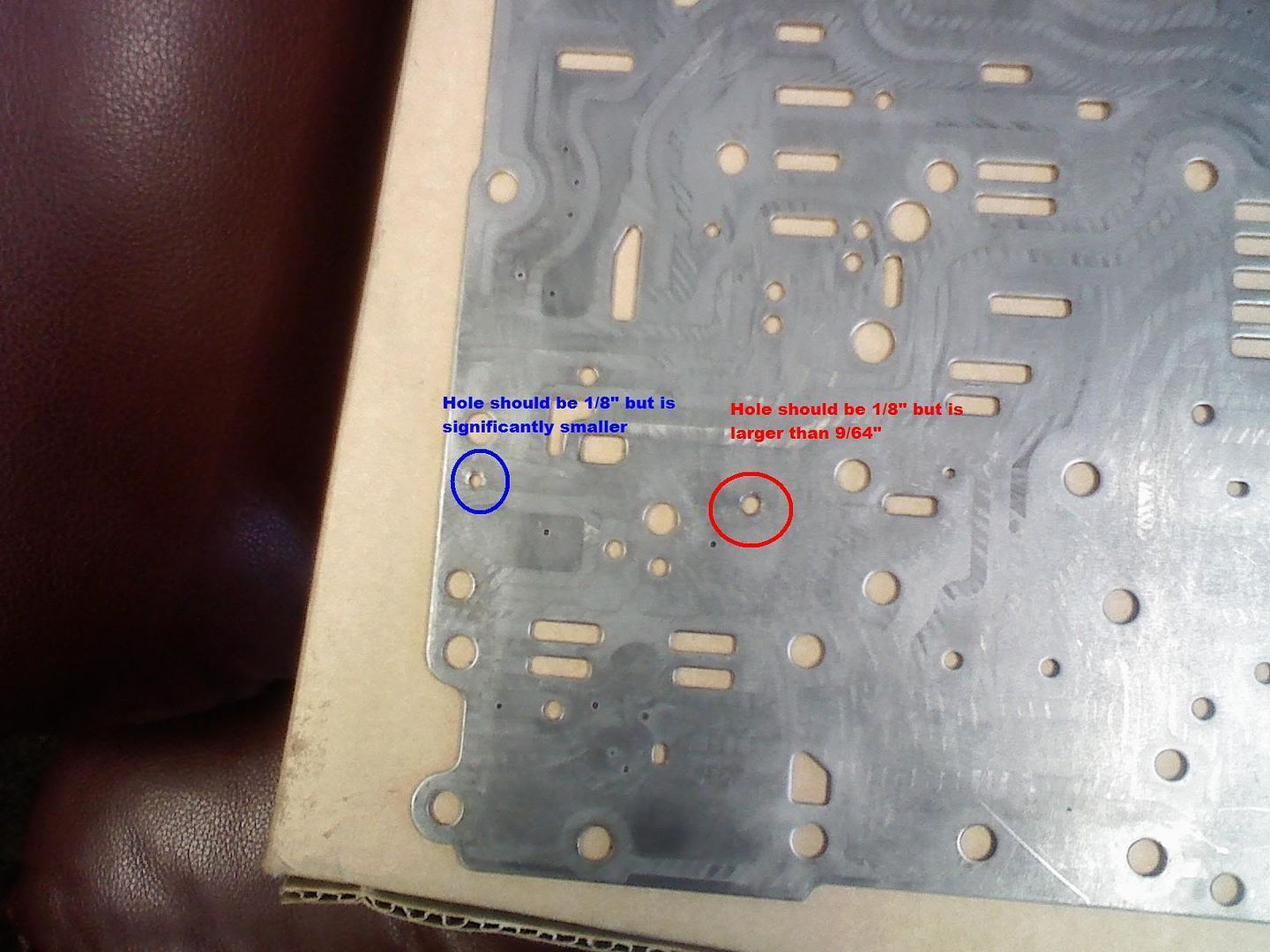

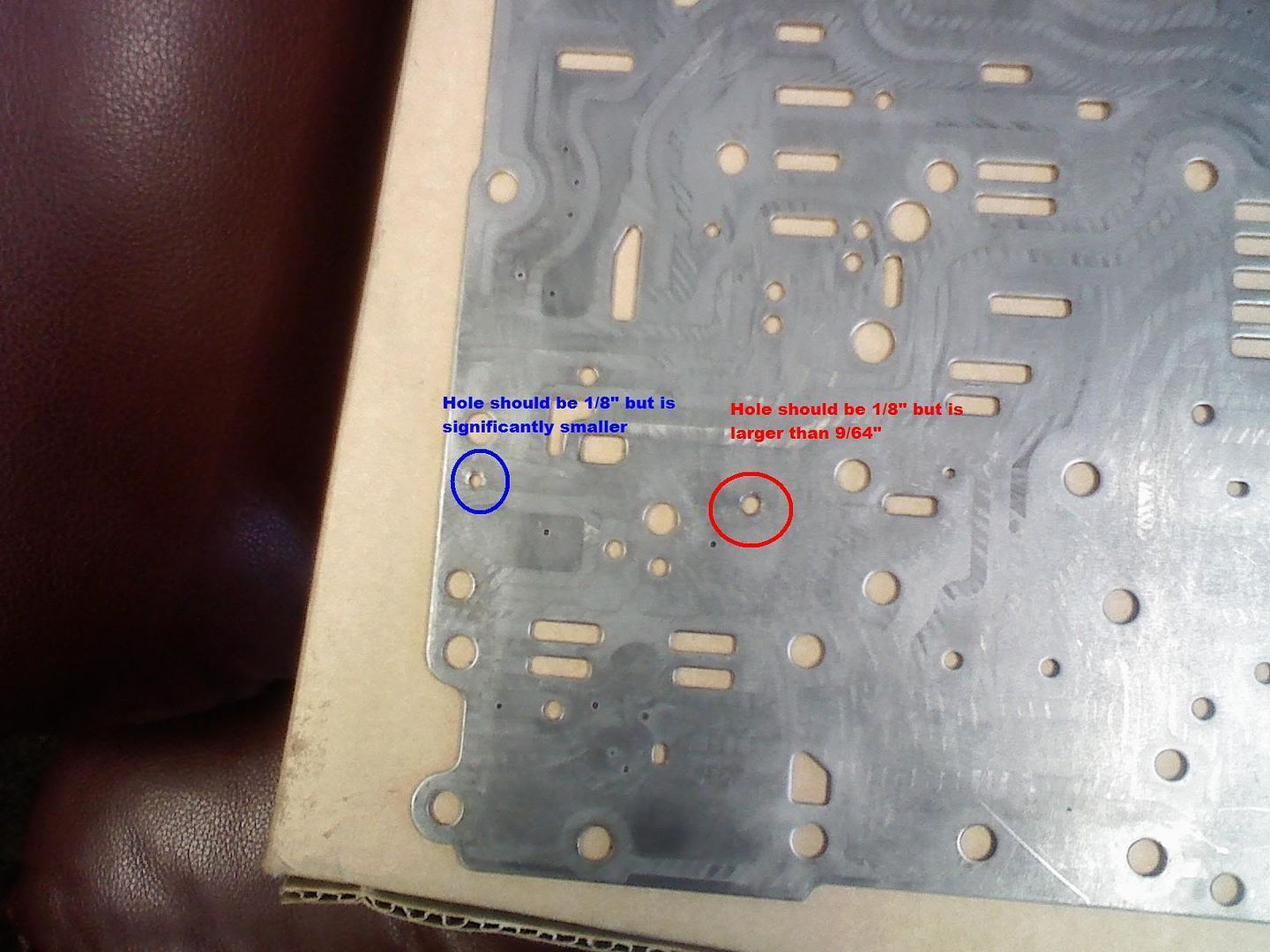

- Valve body separator plate was improperly drilled - one hole was drilled to less than 1/8", while the other was 9/64" (both should be 1/8"). This may seem like a small difference but is actually a 26% increase in flow through the larger hole.

Here are pictures of the torn C3 apply piston and separator plate:

Just the labor here brought him up to what it would have cost him to have me build it right (and stand behind it). Then tack on the parts that had to be replaced (C3 apply piston, C3 clutches, separator plate), machining to get proper clearance, fluids, filters, and his bill at Per4mance Innovations and he is way over the price he "couldn't afford" in the first place. Moral of the story is that if you can't afford to have it done right the first time by a shop that knows what they are doing and stands behind their work, will you be able to afford to have it fixed?