Not much new with the truck, have to get the exhaust one for the tunes, and haven't had any time. Been working on the Porsche.

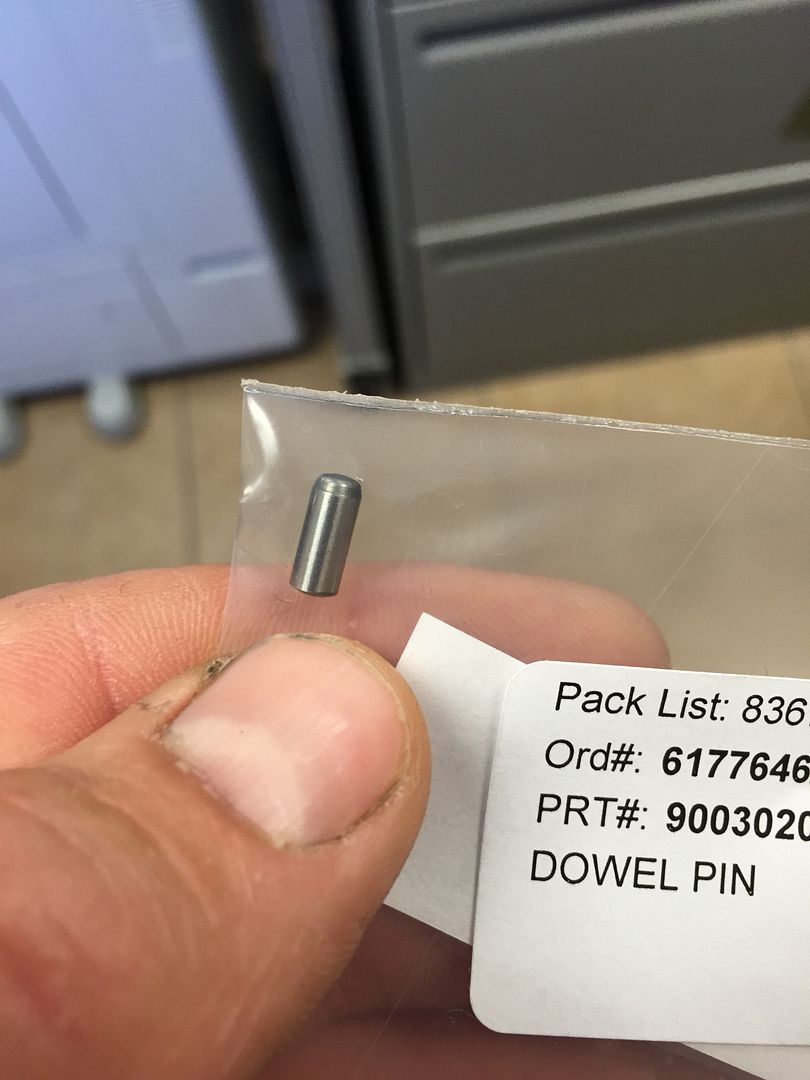

Well I worked at the dowel pin and they DO NOT come out. I bought $300 worth of bits that did not even scratch it.

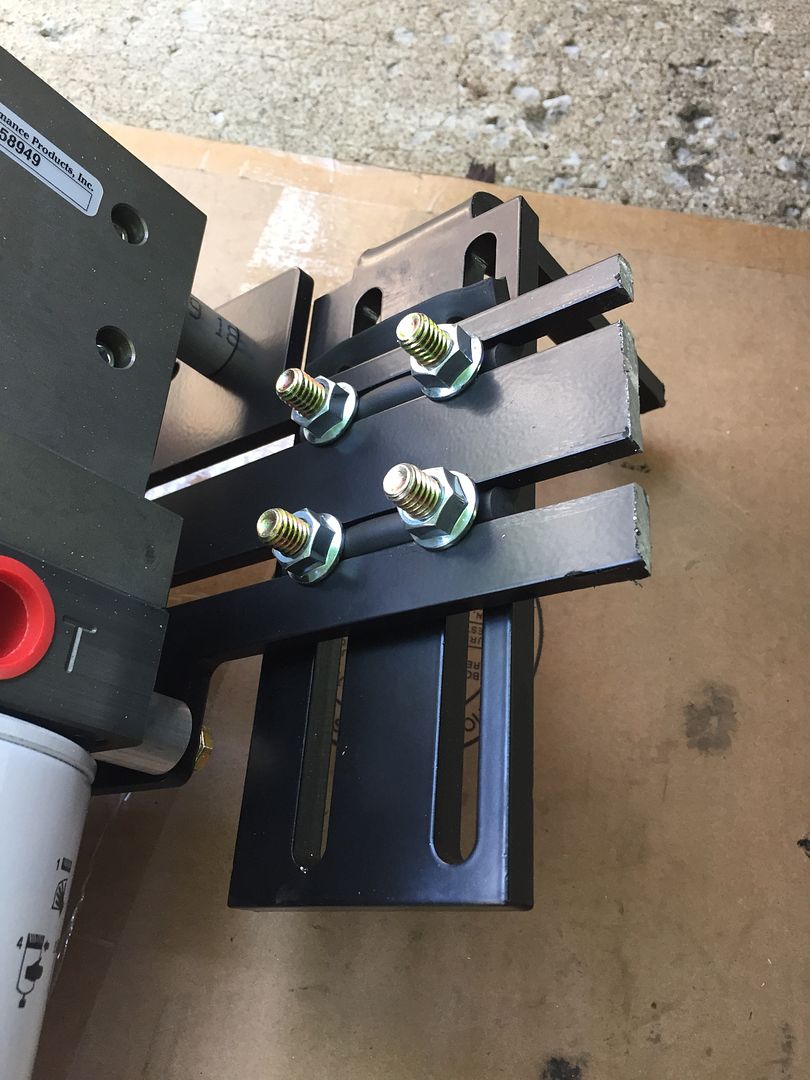

I had a fixture/drill guide made buy a local machinist that I could use to drill the crank for a new pin. In the Corvette world we do this when installing superchargers so the balancer doesn't spin on the crack with the extra drag.

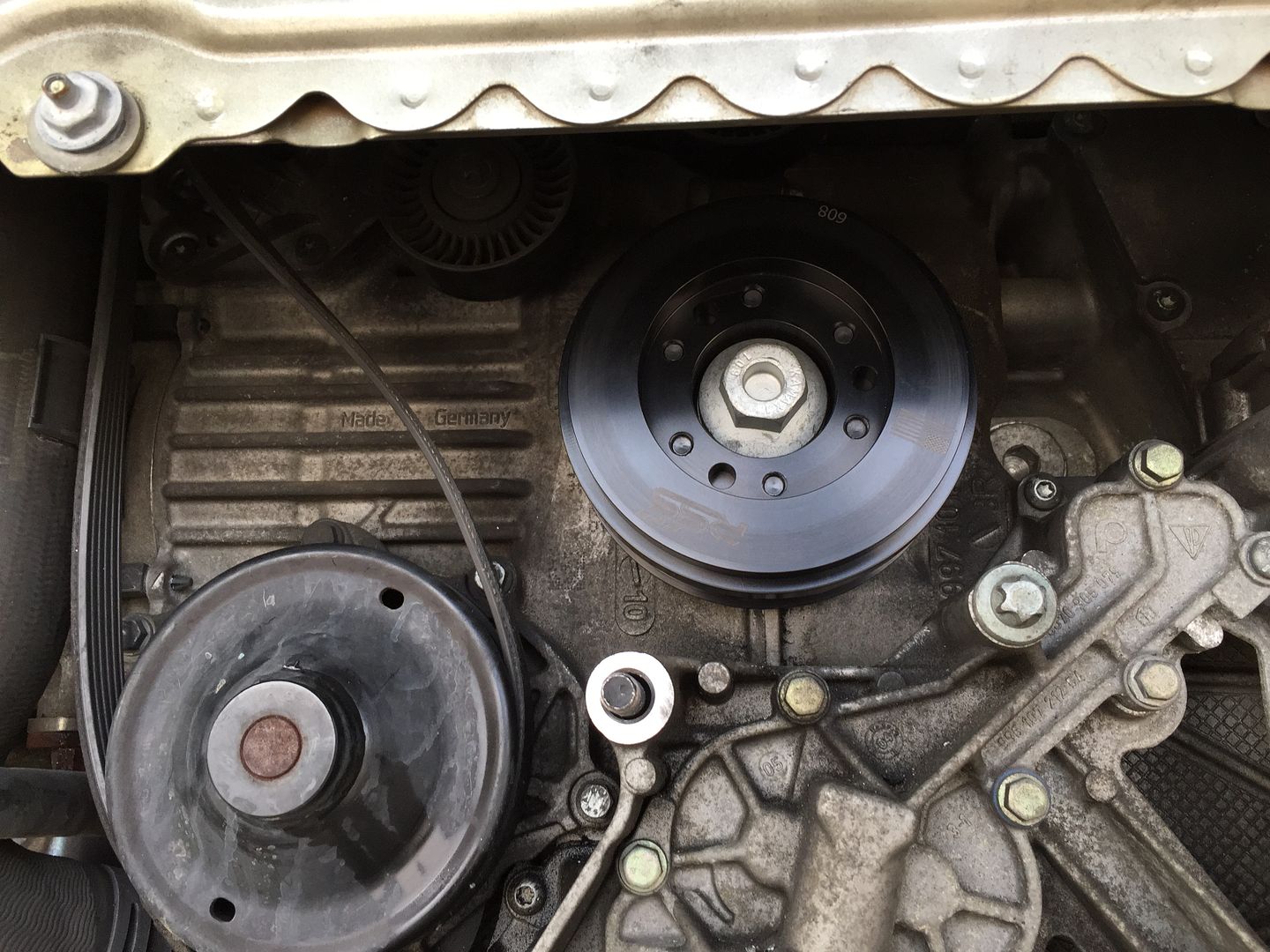

Well it worked. Crazy thing is the pin is 10mm long, so that tells me the factory hole has to be more than 10mm deep for it to bury itself. I chose to drill a 5mm hole in the crank leaving me 5mm out to index with the balancer.

The culprit:

New hole (was a real b*tch to drill this):

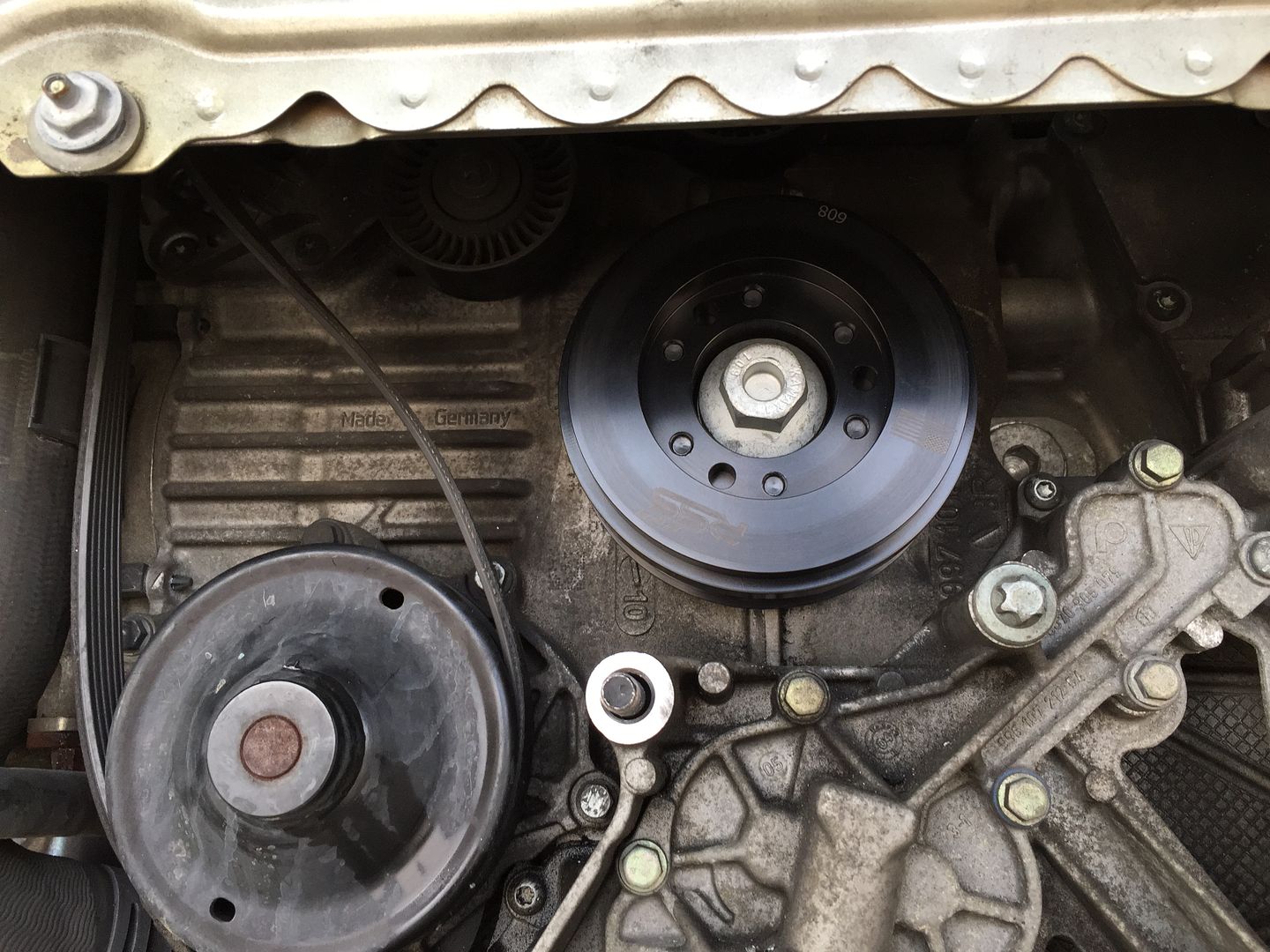

New balancer on and Loctite like crazy on the dowel and new crank bolt:

Buttoning it all back up:

My pops came down and helped me wash it off and then took it to his house to store in the barn.

ITS ALIVE:

It's back alive - YouTube

HUGE thanks to the parts guys at Isringhausen and the RSS for the quick turn around on the parts with the holidays.

I will have to say that these cars are way way way way way easier to work on that people make them out to be. My C5/6 Corvettes are a bigger pain to do the driveline on than this car.