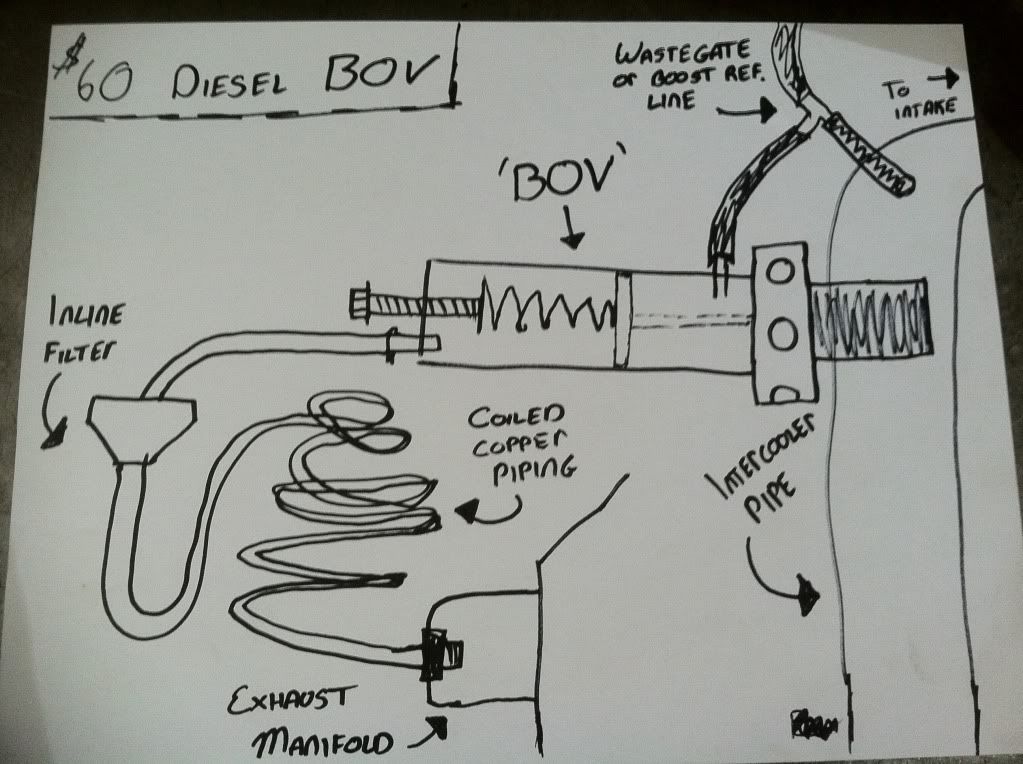

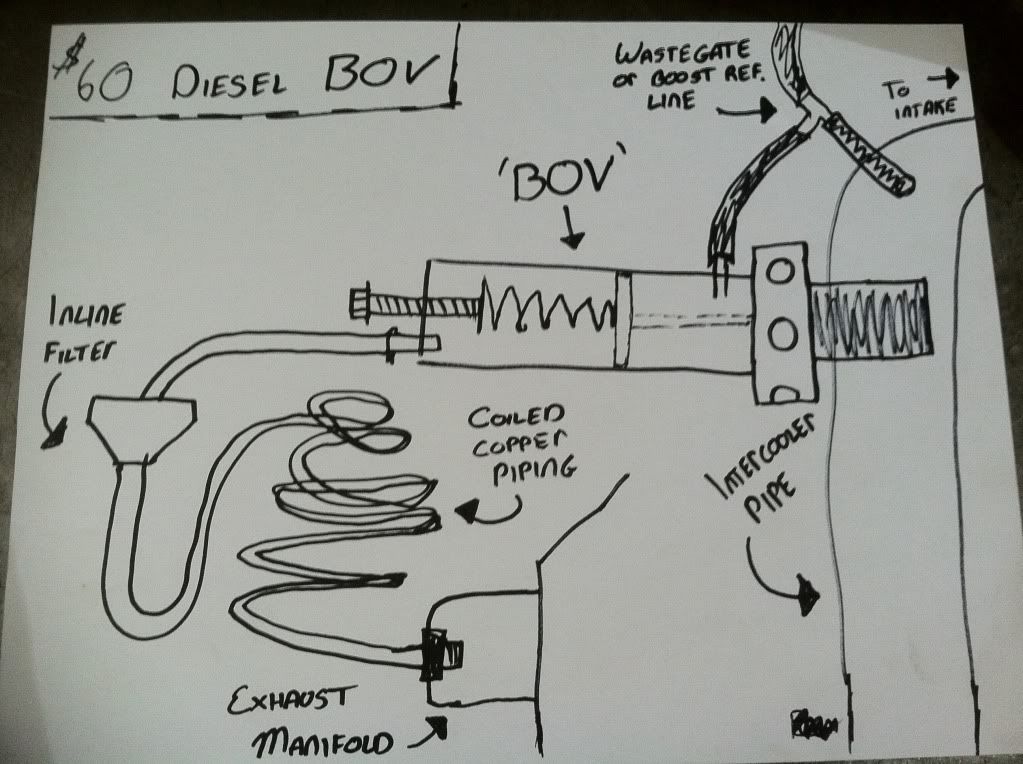

That's a pic when I was first trying it out. And yes it was bolted onto the pipe at that time haha. Its all welded up now. And here is my professional diagram of what I did:

The picture shows what is actually inside of the blow off valve. There is a piston in the middle with a pressure port on each side of it, and then an adjustable spring pushing on only one side of the piston. Then there is a little rod tied into the piston which runs down and controls the actual 'valve' that opens and closes the port to your intake. The valve I used is a cheapo one off of craigslist made to be used on a turbocharged gasoline engine. I tapped into my waistgate boost line and ran that to the 'Boost Reference' port on the valve. And then I took some copper tubing and installed it into my passenger exhaust manifold. Coiled it about 4-6 times to allow for ample cooling, installed a little filter, then ran that hose to the 'Intake Manifold' reference port on the valve. I'm basing this setup off of a 1:1 boost-to-drive pressure ratio as it makes explaining it easy.

So at idle/low boost operation there is not much going on. Boost pressure and drive pressure are on the low side with very minimal differences. The spring pressure helps guarantee the valve is staying in the shut position.

Under high boost, say 30psi, the BOV now has 30psi on one side of the piston and roughly 30-35psi for drive pressure on the other side of the piston. So since the pressure on the drive pressure side is the same (if not a bit higher than boost pressure) along with the spring helping out, the valve stays in the closed position.

Now lets chop the throttle, under full boost, with a loose unlocked converter. Drive pressure drops due to loss of heat and rpm. But yet there still is boost pressure in the intake. So now there is 30psi on the boost side of the valve yet no pressure on the exhaust drive pressure side. This pressure difference overcomes the little spring inside of the valve and PSSSHHHHH

Each setup will be different though. It took me a lot of fine tuning to get it perfect. The original spring in the BOV will more than likely need to be changed out for a very soft spring, as its designed to overcome vacuum in a gasoline engine. I'm still experimenting with the filter in the drive pressure line. I used a tiny lawn mower fuel filter for it and it got clogged pretty quick and effected the response time of the valve. So right now I have no filter in it. Really not that bad. I just have to take the valve apart about once a year to clean.

Another fine tuning adjustment I had to make was to put a one-way check valve in the 'boost reference' line going into the BOV. This helped keep the valve open longer since there is a lot more air in a diesel charge air system vs typical gasoline. Also, I tapped into the wastegate line which is on the complete other side of the charged air system. This I believe helped keep the valve open just slightly longer as it would see a longer boost signal with the valve open due to the air having to move through the intercooler to the other side where the BOV was.

The spring and the check valve will be the biggest variable in how long the valve stays open and what conditions it opens. I noticed with mine if I go full boost and chop the throttle then instantly get on it again, sometimes the valve will stay open a bit longer. But I never really do that so its fine. ZF6 trucks may need to fine tune a bit more.

Oh yea, don't use clear water hose like I did. It tends to melt when your towing a camper over the Rocky Mountains haha.