So, I've been looking at why cranks fail and what we might be able to do about it. I don't see this turning into a product, so I am going to open this up to the community.

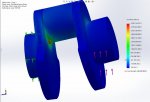

I'll open with a simplified model of the first throw of the crank and a representation of only the Max force from a single piston firing. Note the location of the concentrated stress. (red) Exactly where the cranks break.

I'll open with a simplified model of the first throw of the crank and a representation of only the Max force from a single piston firing. Note the location of the concentrated stress. (red) Exactly where the cranks break.