I decided it was time to share my camaro with you guys. I've had a thread about it over on competitiondiesel.com for a couple months now. The thread can be seen here:

http://www.competitiondiesel.com/forums/showthread.php?t=141513

I bought my Camaro from my mom when I was 18 and built it as a high school "senior project" which was required for graduation. After I graduated, I drove it around town and to work all summer, until it started raining in October of '06. Since it had quite a bit of rot (or at least what I considered quite a bit) I decided it was time to tear it all apart and restore the body.

I had the body dipped to remove all the rust, bondo, etc. and got to see what I was up against. It became clear that it was wrecked a couple times in the early to mid 70's before my mom owned it and was "repaired" very poorly. It needed a lot of work.

As time went on, money became scarce, family became divided, and my car sat for 6 years. So in January of '12, I decided it's now or never. I made a deal with my boss to keep my Camaro at the body shop I work at so I could work on it and fix it the way it should be fixed. I've tried my best to take as many pictures as I could along the way. All of the body work was done by me.

Day 1 right after my lunch break from trailering to the shop and mounting it on my rotisserie.

Super Bowl Sunday morning started cutting out the old sheet metal. The rest of these were taken over about a 6 week period working on Saturdays.

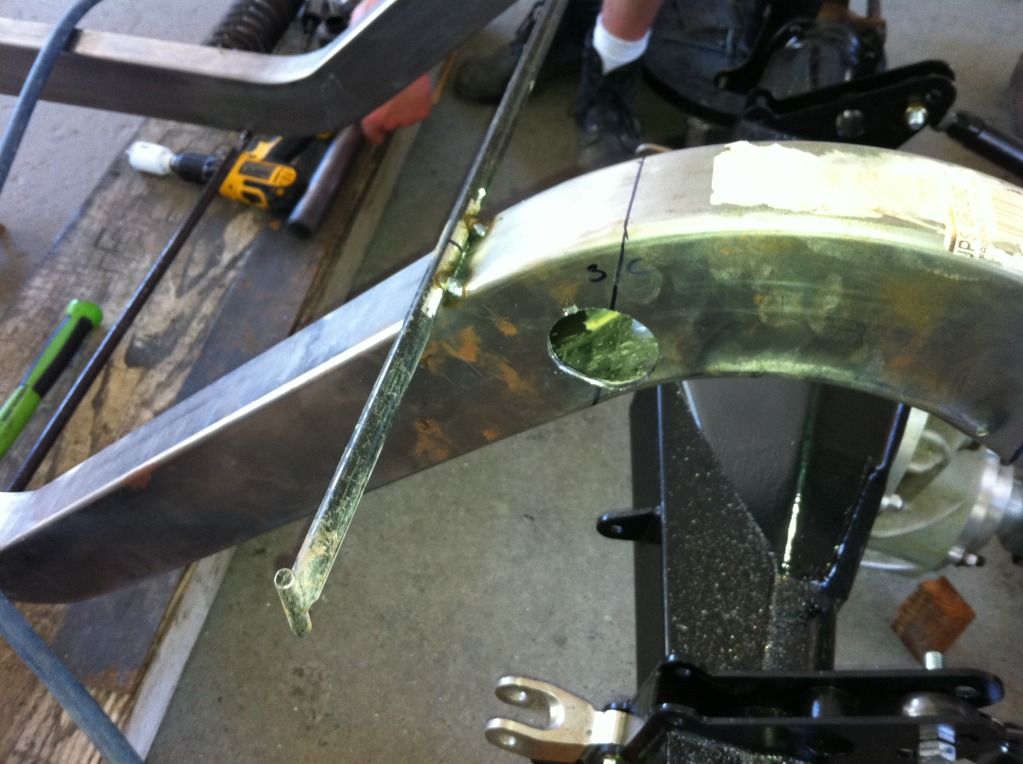

I had attempted to replace a crumpled frame rail a few years back and realized it was a lost cause. You can see the end of it through a cut out in the trunk floor.

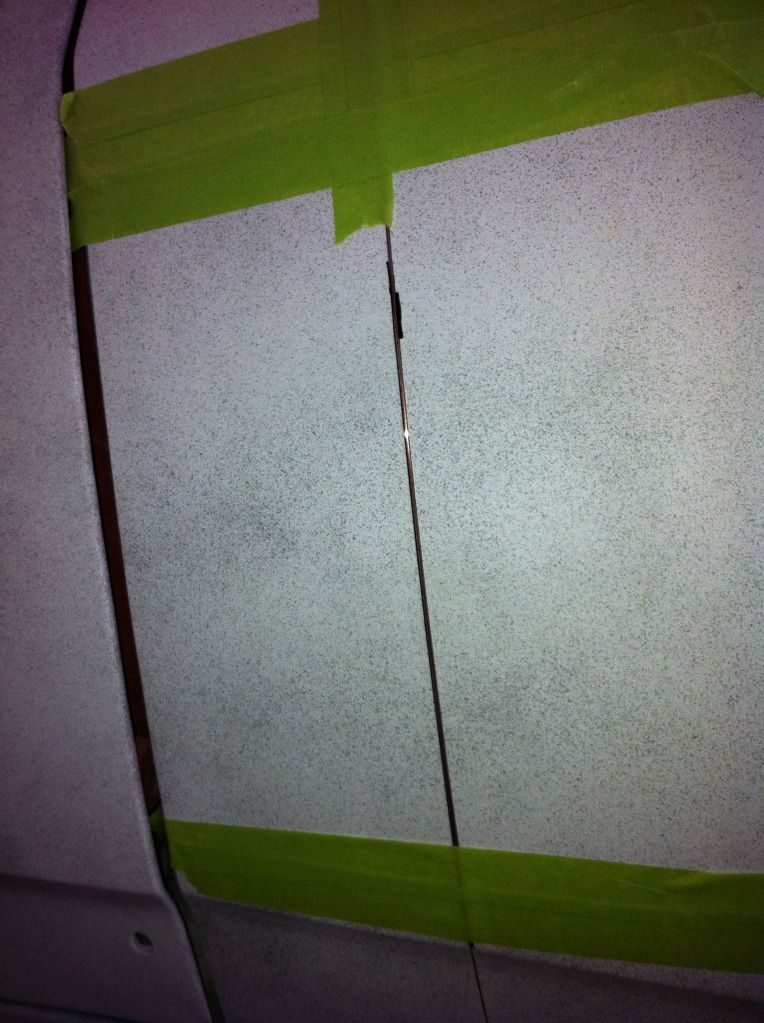

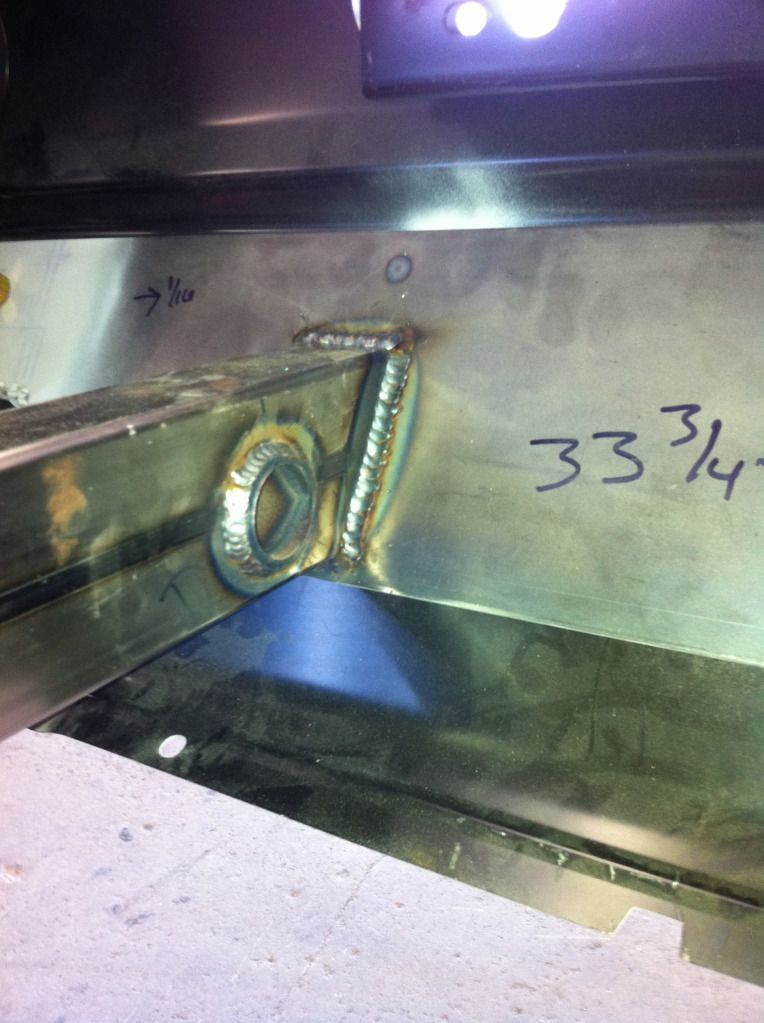

A shot of the new rocker panel spliced in.

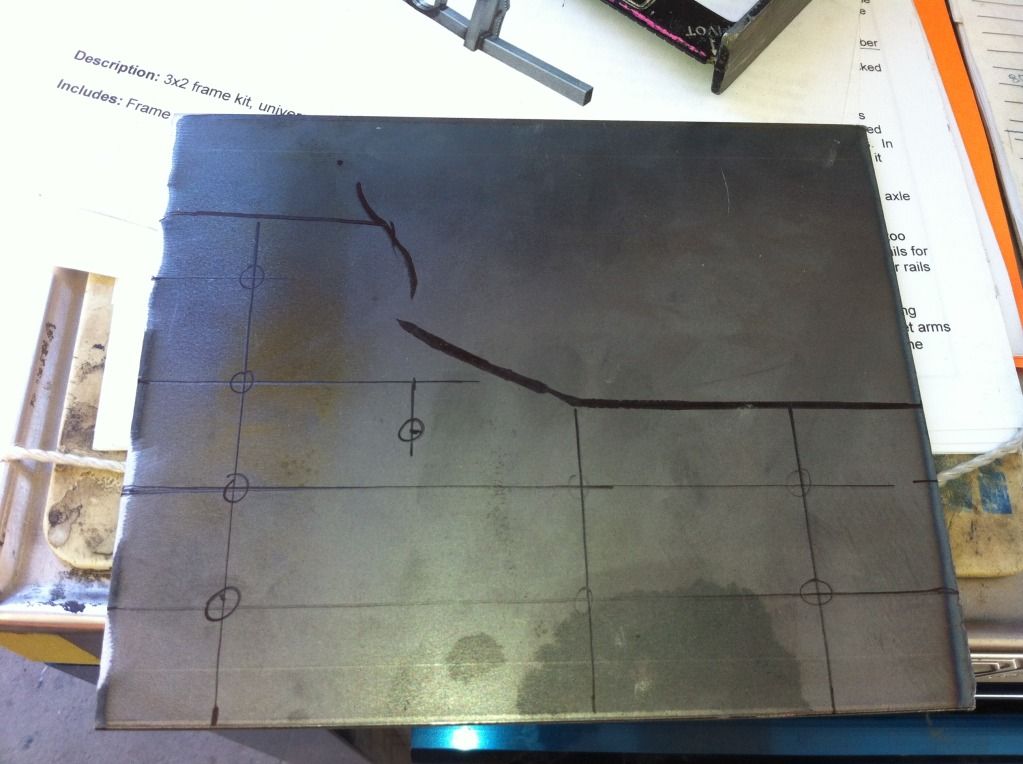

New right quarter test fit.

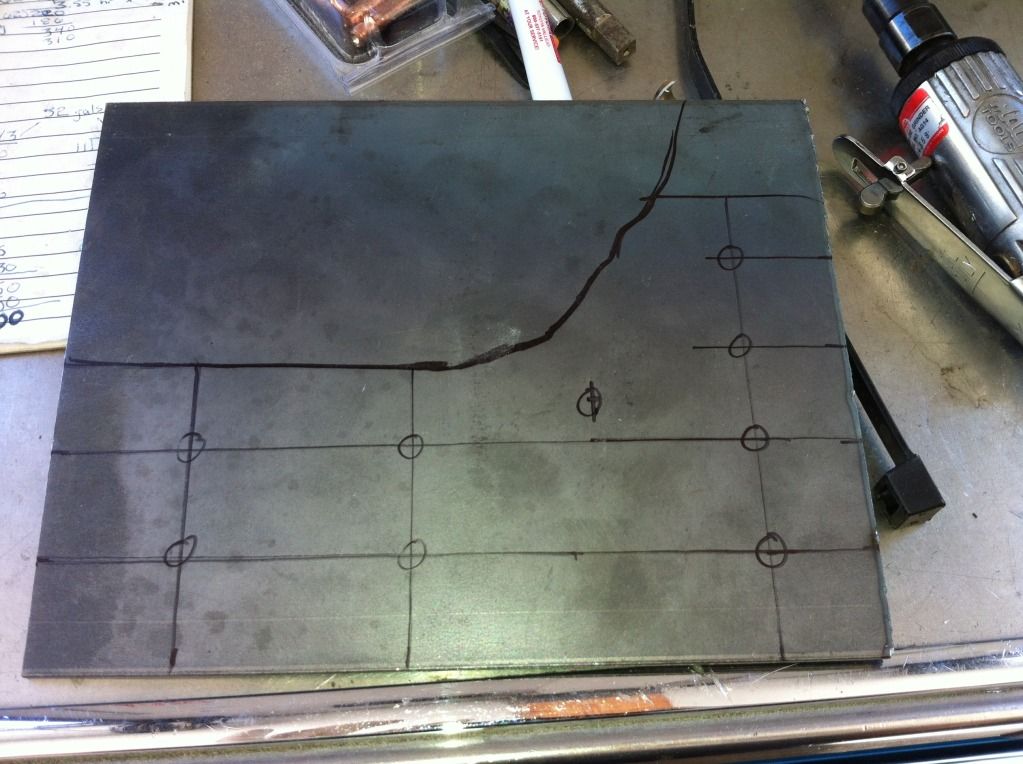

New tail panel test fit.

http://www.competitiondiesel.com/forums/showthread.php?t=141513

I bought my Camaro from my mom when I was 18 and built it as a high school "senior project" which was required for graduation. After I graduated, I drove it around town and to work all summer, until it started raining in October of '06. Since it had quite a bit of rot (or at least what I considered quite a bit) I decided it was time to tear it all apart and restore the body.

I had the body dipped to remove all the rust, bondo, etc. and got to see what I was up against. It became clear that it was wrecked a couple times in the early to mid 70's before my mom owned it and was "repaired" very poorly. It needed a lot of work.

As time went on, money became scarce, family became divided, and my car sat for 6 years. So in January of '12, I decided it's now or never. I made a deal with my boss to keep my Camaro at the body shop I work at so I could work on it and fix it the way it should be fixed. I've tried my best to take as many pictures as I could along the way. All of the body work was done by me.

Day 1 right after my lunch break from trailering to the shop and mounting it on my rotisserie.

Super Bowl Sunday morning started cutting out the old sheet metal. The rest of these were taken over about a 6 week period working on Saturdays.

I had attempted to replace a crumpled frame rail a few years back and realized it was a lost cause. You can see the end of it through a cut out in the trunk floor.

A shot of the new rocker panel spliced in.

New right quarter test fit.

New tail panel test fit.