Twins with Twins, Anyone?

- Thread starter kidturbo

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

For now we are gonna call it a fluke issue, unless the autopsy says otherwise.. But since we have two engines, if she guts that other 12mil, then we will know where to start cutting new gear sets ..

I guess it depends on what caused the failure, but do you think dropping to a 10mm would be easier on the internals?

Reminder to myself never to post in the "what did you do at work" thread ever again.....My kid is a UPS center mgr, and he gave me 50/50 odds on that CP3 overnight yesterday based on Louisville volume and exceptions. Buddy of mine got stuck in Nashville airport for two days from Sunday. But why the heck they can't get air freight outa GA has got me. Ground would have made here it by now...

My pump made it on time, your clear. LoLReminder to myself never to post in the "what did you do at work" thread ever again.....

Sent from my SM-G892A using Tapatalk

No definitive answer yet on the cause of CP3 failure, but was promised a full run down next week. We did however go over some possible measures to lessen chance of future problems. In similar application with high sustained RPM over long periods, backing the rail pressure down to around 26k has shown good results. This discovered due to a customers super low lubricity fuel usage. Verified it so on C platform, and gonna ask a friend in cali if that's same line on the D platforms. However think I'm the only setup running stroked pumps under these same high RPM conditions. May have to consider adjusting the tuning to compensate up top. Cause just looking back at my tach recall pics and videos to date, seems I do spend the majority operating time above the 3000rpm line. That time being in minutes only so far.. lol

I'm curious, did they say pressures over 26k exceed the MAWP of their pump, or just that for your intended duration of load and 26k+ pressure, it was not going to survive?

Last edited by a moderator:

Not a known issue with any of Exergy stuff. However pressure related wear has been noted in other Bosch units that run sustained high rpm on say l, Jet A.

Sent from my SM-G892A using Tapatalk

Sent from my SM-G892A using Tapatalk

No definitive answer yet on the cause of CP3 failure, but was promised a full run down next week. We did however go over some possible measures to lessen chance of future problems. In similar application with high sustained RPM over long periods, backing the rail pressure down to around 26k has shown good results. This discovered due to a customers super low lubricity fuel usage. Verified it so on C platform, and gonna ask a friend in cali if that's same line on the D platforms. However think I'm the only setup running stroked pumps under these same high RPM conditions. May have to consider adjusting the tuning to compensate up top. Cause just looking back at my tach recall pics and videos to date, seems I do spend the majority operating time above the 3000rpm line. That time being in minutes only so far.. lol

I'm curious, did they say pressures over 26k exceed the MAWP of their pump, or just that for your intended duration of load and 26k+ pressure, it was not going to survive?

It is more a fuel quality(lubricity) vs pressure and heat generated for a sustained time period as the fuel can get pretty hot under load especially when you are cranking that kinda rpms and pressure. We have run their pumps from 29-34K PSI in competition use but Ken's situation is different than anyone else's so its a different learning curve.

Last edited by a moderator:

Maybe run a short section of the high pressure fuel line through the coolant system to keep the fuel temperature from getting to high? Or is it only at the pump that is the problem, and submerging it would be impractical?

The fuel returns run through a liquid to liquid cooler on front of the engine. Plus it's got a 300gal fuel tank capacity. I ditch the factory fuel temp sensors and use the ecm input and pid to monitor oil temp on the marine stuff. That also lets me defuel on oil temp and IAT 2, which is ultimately more important. But I'll stick a temp sensor on the port where it goes back into the tank and check it for good measure..

Main reason I wanted Exergy to do a full inspection is to tell if any excessive wear is detected at such low hours. Stuff breaks, so if it's just a one off problem, ya move on and hopefully everyone learns something to improve next design. But still gonna get a tune ready with a little less pressure and see how they run.

Main reason I wanted Exergy to do a full inspection is to tell if any excessive wear is detected at such low hours. Stuff breaks, so if it's just a one off problem, ya move on and hopefully everyone learns something to improve next design. But still gonna get a tune ready with a little less pressure and see how they run.

Question for Mark, having been a huge proponent for higher pressures for making more power for years, have you also tested any modifications to injectors and, say piston bowl design, to optimize power at lower injection pressures?

In general, I wonder if a water-cooled pump case would be beneficial for marine use?

In general, I wonder if a water-cooled pump case would be beneficial for marine use?

Question for Mark, having been a huge proponent for higher pressures for making more power for years, have you also tested any modifications to injectors and, say piston bowl design, to optimize power at lower injection pressures?

In general, I wonder if a water-cooled pump case would be beneficial for marine use?

Yes Tim, and it always works better at higher pressures and is part of the reason why the OE stuff overseas is approaching the 36-40K psi operating range now because it is a cleaner more controlled event with the higher pressure. Lowering the pressure causes the injection event to be slowed down and actual timing to be lowered so if you went that route you would have to crank up the timing and such but you will still end up with a less than desired combustion event because it isn't going to be atomized as well and the air fuel mixture will not be as even across the piston as you would like it to be. Pre cooling the fuel would be a great idea at that point since the pump is also lubricated by the fuel itself so cooler fuel will help keep the pump temperatures down also which would have to be better in this situation.

Yes Tim, and it always works better at higher pressures and is part of the reason why the OE stuff overseas is approaching the 36-40K psi operating range now because it is a cleaner more controlled event with the higher pressure. Lowering the pressure causes the injection event to be slowed down and actual timing to be lowered so if you went that route you would have to crank up the timing and such but you will still end up with a less than desired combustion event because it isn't going to be atomized as well and the air fuel mixture will not be as even across the piston as you would like it to be. Pre cooling the fuel would be a great idea at that point since the pump is also lubricated by the fuel itself so cooler fuel will help keep the pump temperatures down also which would have to be better in this situation.

I also wonder if pre-heating the fuel prior to cooling, and incorporating a separator to trap the asphaltines (abrasives) would help? Or as a bypass setup, add the separator on the return side of the pump where the unused fuel is still hottest?

These are just theoreticals. The heat produced by the delta in pressure in the pump is something we can't address directly it seems. Initially guaranteeing fuel quality, for competition vehicles, may prove to be the most efficient way to combat these issues? But for the larger market, at this point, adding lubricity additive, filtering, controlling fuel temps, and being conservative with injection pressure seems to be the most effective path to reliability, right?

Last edited:

Different fuel characteristics respond differently in the combustion process. Most of you might know the BTU and octane based differences such as those in ethanol, methanol, vs gasoline. But there are similar difference in oil's such as K1, D1, D2, Jet-A or Jet-B blends. Then we can get deeper into alternatives such as biodiesel blends. Last time at UCC, I was pleasantly surprised to smell french fries coming outa the stacks of multiple competitors.

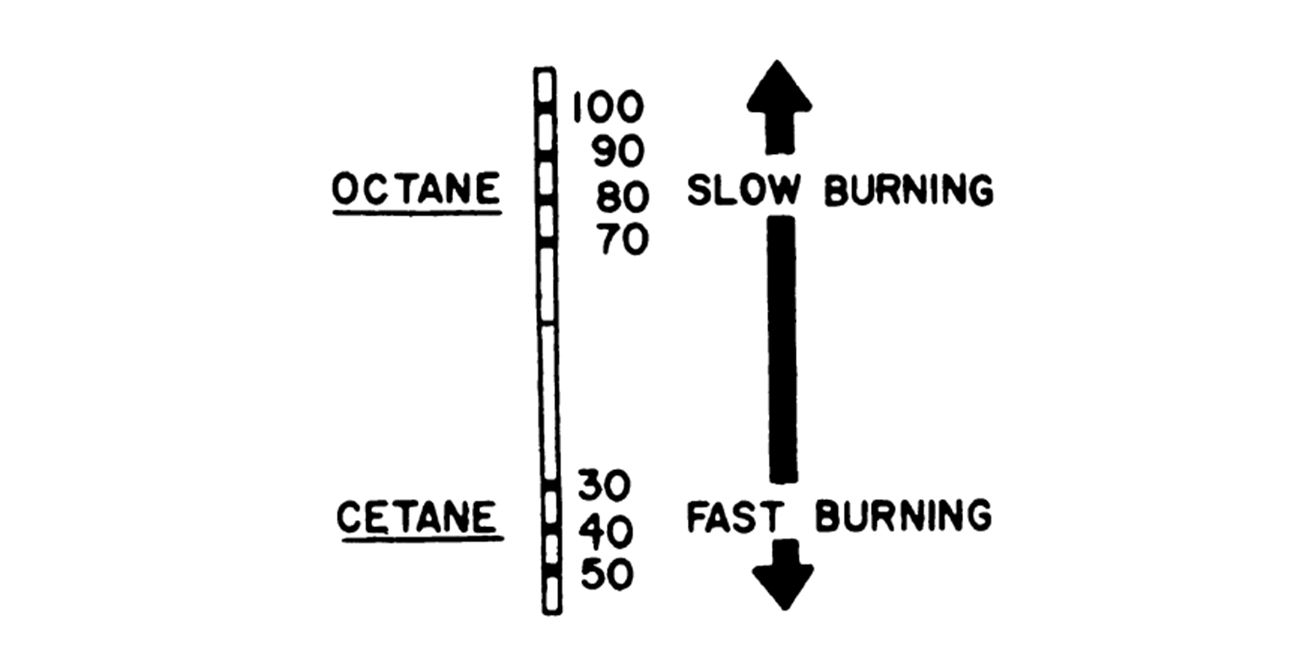

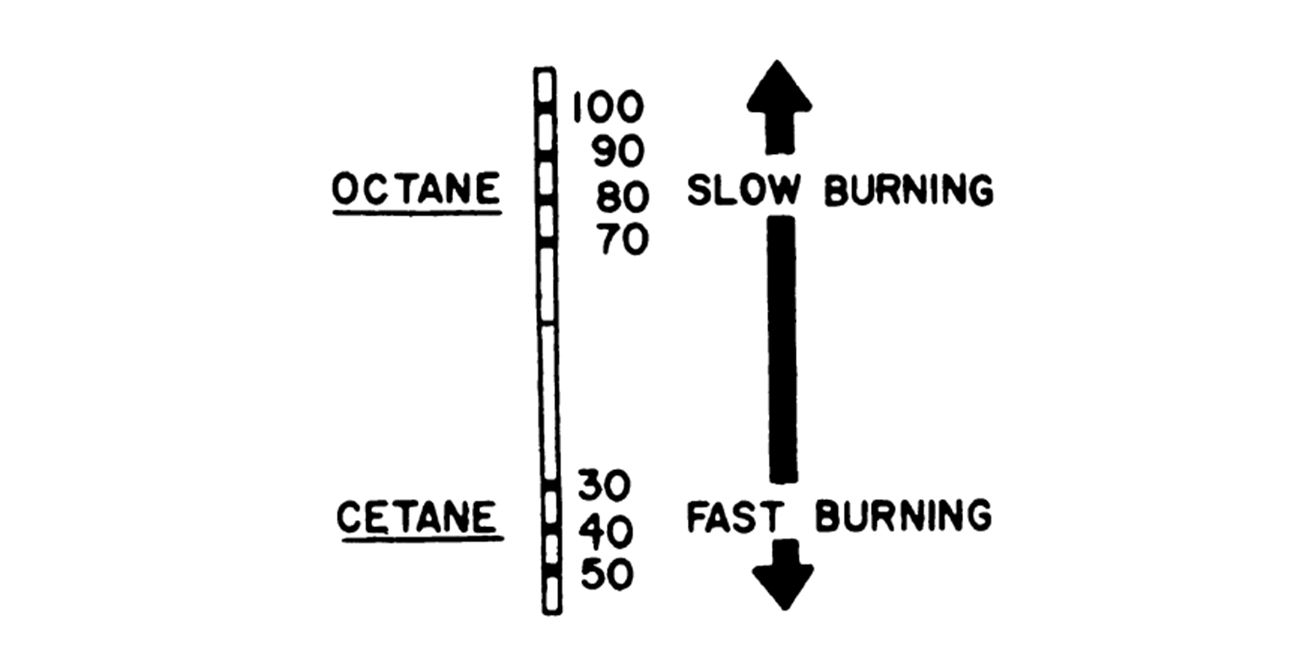

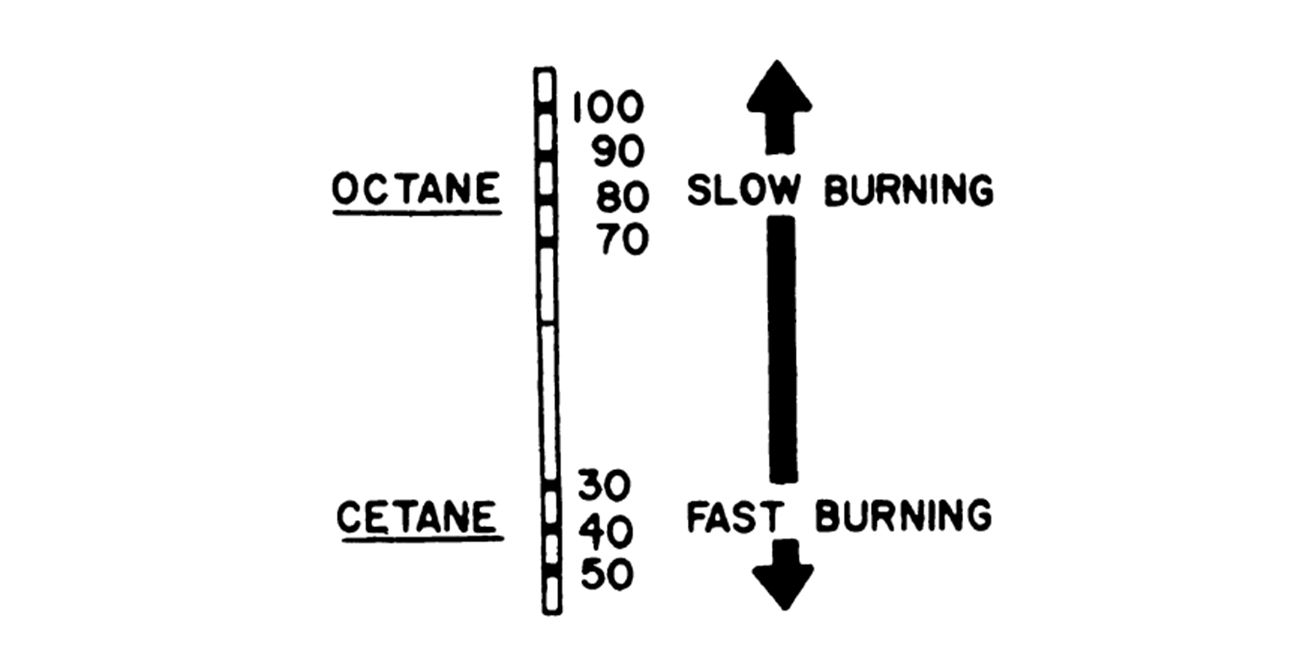

Leaning about, then becoming a commercial Biodiesel producer is what got me into these dang Duramax powered boats. When I bought the original PPE boat in 09, it was for promoting biodiesel as a performance fuel. Lubricity is 70x higher than D2, and Cetane is typically in the mid 50's. But it also has about 10k less BTU's than D2. So in a pure form it ignites easier [at lower temps] and burns faster [cetane] , but has less overall power potential due to lower BTU's. Reason diesels smoke less and sound quieter on bio blends. It also contains some attached oxygen molecules like Methanol, which can potentially make more power if you stuff more of it in the cylinders. So blending biodiesel [and other oxygenation additives] into D2 can equal nice performance gains if you understand how to tune for it.

How does all this play into our discussion here? Lubricity, Cetane, and Atomization. Jet-A is basically straight K1 with very little gasoline blended. Jet-B is K1 with a bunch of gasoline in it. Both have the lubricity of tap water. Where as D2 or straight diesel what we run in the summer, where D1 is blended with some K1 for winter anti-gel characteristics. Hence crappy fuel mileage in the winter, but good mileage in the summer... But these differences also impact how each fuel performs in the cylinders, and most notably torque based on timing.

While most of you are now likely wonder why would anyone run straight Kerosene in a modern common rail diesel, the answer is straight up availability. Our gov camo tanker jockeys prefer to roll around with just one type of fuel type to supply everything they run. That's Jet-A. And while it's noted that CP3 pumps might operate differently between D1 and Jet-A. Likely just a lubricity issue when PSI gets jacked up. Adding some lube additives or biodiesel will likely fix any problems, lowering the pressure helps too. We just don't have a lot of data from the performance side. It's gonna suffer on power, but timing might resolve it. However we plan to always run B20 once we get to that point I don't risk parking the boat with 300 gallons of Biodegable fuel onboard...

petroleumservicecompany.com

petroleumservicecompany.com

Leaning about, then becoming a commercial Biodiesel producer is what got me into these dang Duramax powered boats. When I bought the original PPE boat in 09, it was for promoting biodiesel as a performance fuel. Lubricity is 70x higher than D2, and Cetane is typically in the mid 50's. But it also has about 10k less BTU's than D2. So in a pure form it ignites easier [at lower temps] and burns faster [cetane] , but has less overall power potential due to lower BTU's. Reason diesels smoke less and sound quieter on bio blends. It also contains some attached oxygen molecules like Methanol, which can potentially make more power if you stuff more of it in the cylinders. So blending biodiesel [and other oxygenation additives] into D2 can equal nice performance gains if you understand how to tune for it.

How does all this play into our discussion here? Lubricity, Cetane, and Atomization. Jet-A is basically straight K1 with very little gasoline blended. Jet-B is K1 with a bunch of gasoline in it. Both have the lubricity of tap water. Where as D2 or straight diesel what we run in the summer, where D1 is blended with some K1 for winter anti-gel characteristics. Hence crappy fuel mileage in the winter, but good mileage in the summer... But these differences also impact how each fuel performs in the cylinders, and most notably torque based on timing.

While most of you are now likely wonder why would anyone run straight Kerosene in a modern common rail diesel, the answer is straight up availability. Our gov camo tanker jockeys prefer to roll around with just one type of fuel type to supply everything they run. That's Jet-A. And while it's noted that CP3 pumps might operate differently between D1 and Jet-A. Likely just a lubricity issue when PSI gets jacked up. Adding some lube additives or biodiesel will likely fix any problems, lowering the pressure helps too. We just don't have a lot of data from the performance side. It's gonna suffer on power, but timing might resolve it. However we plan to always run B20 once we get to that point I don't risk parking the boat with 300 gallons of Biodegable fuel onboard...

Deisel Fuel grades

Recently told to use D2 deisel (ULSD) in our new truck. Can someone explain what different types of deisel fuels are out there, what the differences are?

www.expeditersonline.com

JET-A And JET-B Fuels Whats The Diffrence? - Airliners.net

www.airliners.net

The Difference Between Cetane and Octane

Whether you realize it or not, you've seen octane ratings on a regular basis. It's what makes one type of gas at the gas station more expensive than another. The octane ...

Last edited:

Different fuel characteristics respond differently in the combustion process. Most of you might know the BTU and octane based differences such as those in ethanol, methanol, vs gasoline. But there are similar difference in oil's such as K1, D1, D2, Jet-A or Jet-B blends. Then we can get deeper into alternatives such as biodiesel blends. Last time at UCC, I was pleasantly surprised to smell french fries coming outa the stacks of multiple competitors.

Leaning about, then becoming a commercial Biodiesel producer is what got me into these dang Duramax powered boats. When I bought the original PPE boat in 09, it was for promoting biodiesel as a performance fuel. Lubricity is 70x higher than D2, and Cetane is typically in the mid 50's. But it also has about 10k less BTU's than D2. So in a pure form it ignites easier [at lower temps] and burns faster [cetane] , but has less overall power potential due to lower BTU's. Reason diesels smoke less and sound quieter on bio blends. It also contains some attached oxygen molecules like Methanol, which can potentially make more power if you stuff more of it in the cylinders. So blending biodiesel [and other oxygenation additives] into D2 can equal nice performance gains if you understand how to tune for it.

How does all this play into our discussion here? Lubricity, Cetane, and Atomization. Jet-A is basically straight K1 with very little gasoline blended. Jet-B is K1 with a bunch of gasoline in it. Both have the lubricity of tap water. Where as D2 or straight diesel what we run in the summer, where D1 is blended with some K1 for winter anti-gel characteristics. Hence crappy fuel mileage in the winter, but good mileage in the summer... But these differences also impact how each fuel performs in the cylinders, and most notably torque based on timing.

While most of you are now likely wonder why would anyone run straight Kerosene in a modern common rail diesel, the answer is straight up availability. Our gov camo tanker jockeys prefer to roll around with just one type of fuel type to supply everything they run. That's Jet-A. And while it's noted that CP3 pumps might operate differently between D1 and Jet-A. Likely just a lubricity issue when PSI gets jacked up. Adding some lube additives or biodiesel will likely fix any problems, lowering the pressure helps too. We just don't have a lot of data from the performance side. It's gonna suffer on power, but timing might resolve it. However we plan to always run B20 once we get to that point I don't risk parking the boat with 300 gallons of Biodegable fuel onboard...

Deisel Fuel grades

Recently told to use D2 deisel (ULSD) in our new truck. Can someone explain what different types of deisel fuels are out there, what the differences are?www.expeditersonline.com

JET-A And JET-B Fuels Whats The Diffrence? - Airliners.net

www.airliners.net

The Difference Between Cetane and Octane

Whether you realize it or not, you've seen octane ratings on a regular basis. It's what makes one type of gas at the gas station more expensive than another. The octane ...petroleumservicecompany.com

This is all great info, thanks Ken. I'm going to have to do a lot more homework on this subject now. I thought I did a lot of research back in 07- 11 on biodiesel, but I certainly have a lot more to learn.

There is some good papers out there on biodiesel power and mileage studies. Some of my favorites are by college students who did biofuel mixture studies with old 10-15hp single cylinder diesels on a dyno. Couple even dumped some nitromethane into the mix, which added some nice kick. But main take away is up to 50% bio typically makes more power and better mileage than straight diesel with less timing required.

Sent from my SM-G892A using Tapatalk

Sent from my SM-G892A using Tapatalk

She's back on the water, and such a watched project, my weather man buddy even spotted it at the boat ramp. And I checked the hour meters, 30.6hrs since on the dyno.

Sent from my SM-G892A using Tapatalk

Sent from my SM-G892A using Tapatalk

Was unable to find any Fuchs 762 locally, so I used a permatex 80335 on the mating surface of turbo v-bands flanges. Its rated 2000F, and similar to the stuff I used on the up pipe joint. Then coated the clamps in antisieze and cranked the fuchs outa the T-bolts.

Ran it 5 miles at 50, and first time ever, no exhaust leaks on port.. You could even feel the throttle response diffetence.

Sent from my SM-G892A using Tapatalk

Ran it 5 miles at 50, and first time ever, no exhaust leaks on port.. You could even feel the throttle response diffetence.

Sent from my SM-G892A using Tapatalk