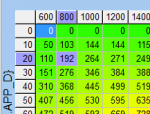

I attempted to adjust the apps voltage scales down in the ECM tables to match observed throttle readings. Tune file loaded fine, but bricks the ECM upon completion.

Good thing I've yet to find a way to actually kill an E35. Try as I may, they always recover... EFI recovery script tested and certified good ... Lol

Sent from a reclined position using Tapatalk

Good thing I've yet to find a way to actually kill an E35. Try as I may, they always recover... EFI recovery script tested and certified good ... Lol

Sent from a reclined position using Tapatalk