So I think its time for some HG's

- Thread starter wsmithduramax

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

if you just done it last year,it should of lasted a longer that this. . .

thats what I would have thought, but then again it was an ac pump number not the GM pump one but who knows, it seems like parts these days are failing fastere and faster even when they are new. I think I'm gonna run a few more test tonight, and then maybe just for shits and grins throw a water pump on there, and then I will have eliminated most of the problems it could be.

yea I agree. Thanks for all your input, I'll see what I can get done this weekend if anything, and I'll keep you guys updated.:thumb:

Thanks for all your input, I'll see what I can get done this weekend if anything, and I'll keep you guys updated.:thumb:

Exactly.

Thanks Ben, I lacked the proper vocabulary after several beers into last night.

:thumb:

That makes sense. I thought you meant "fire ringing" with a steel crush ring. Never seen that done on a duramax.

That makes sense. I thought you meant "fire ringing" with a steel crush ring. Never seen that done on a duramax.

That's what I thought but the ethanol infused lack of comprehension/vocabulary was handicapping me.

Thanks for the added info Wes, does sound like another issue at this point other than HG's. Got my fingers crossed $180 water pump is all u need.

That's what I thought but the ethanol infused lack of comprehension/vocabulary was handicapping me.

Lol. I know the feeling.

Thanks for the added info Wes, does sound like another issue at this point other than HG's. Got my fingers crossed $180 water pump is all u need.

yea I think im gonna try a water pump first, only takes a couple hours to change it out anyway

New two piece water pump

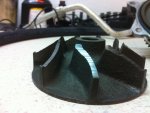

So I'm almost sure that this is my overheating problem. looks like I got one of those NEW two piece water pumps . Dunno if anyone has seen this before, i've heard of the gear spinning on the shaft, but not the impeller. Anyways my dumbass didn't bring home a housing with me and as you can see from the pics I should prolly replace it. So gotta wait till monday. Hope this fixes my problem.:thumb:

. Dunno if anyone has seen this before, i've heard of the gear spinning on the shaft, but not the impeller. Anyways my dumbass didn't bring home a housing with me and as you can see from the pics I should prolly replace it. So gotta wait till monday. Hope this fixes my problem.:thumb:

So I'm almost sure that this is my overheating problem. looks like I got one of those NEW two piece water pumps

Attachments

Yea I think its safe to say that as well. I just wish I wasn't such a dumbass, I even had the part number for the housing and thought there would be no way that could be screwed up. Guess that goes to show what i know

I do have one question about the welding the gear and the impeller, should I use a mig or tig welder or does it even really matter, and should I weld the whole seem or just a tack on each side so I don't get to much heat on it?

some have good luck others dont . I have tried mig and tig and welding all the way around on both impeller and gear neither worked for me . as i said before first failure was impeller just a tack mig on both sides . second was tigged after taking out extra material on both sides near the shaft and tigging it ( lasted less then 200 miles) . there is a thread with more info on it here . both sweetdiesel and othergrl posted some good info on water pump failures . iirc Trent drillls the pump before he welds it and that has worked for him .

some have good luck others dont . I have tried mig and tig and welding all the way around on both impeller and gear neither worked for me . as i said before first failure was impeller just a tack mig on both sides . second was tigged after taking out extra material on both sides near the shaft and tigging it ( lasted less then 200 miles) . there is a thread with more info on it here . both sweetdiesel and othergrl posted some good info on water pump failures . iirc Trent drillls the pump before he welds it and that has worked for him .

Yea I've read several threads about welding the shafts. I asume when you say "trent drills the pump" you mean he drills a cross hole in it and then puts in a roll pin or something is that whay you mean?

hey now i like roll pin ideal!! never thought about that. . .all i did was just weld the sean all the way around the shaft,low heat both sides

I installed a roll pin kit for a guy who was possibly going to install a supercharger on his LS7 vette, and the kit he supplied came with the pin and drill bit. At any rate it just had you drill down the seam of the crank and balancer and drive the pin into the new hole. Should work good if things aren't hardened. I'm currently installing an LBZ pump on my LLY. Only had to modify one tab and heat and lube the hose to put it on. Next time I'll modify the inlet for the proper hose size, if i have any issues. Glad my % were wrong and appears to be an easy fix!

Last edited:

Yea I've read several threads about welding the shafts. I asume when you say "trent drills the pump" you mean he drills a cross hole in it and then puts in a roll pin or something is that whay you mean?

No , I think what he did was drill a good size hole and then welded it . even if the weld breaks around the shaft it sill works to keep everything together like a pin

No , I think what he did was drill a good size hole and then welded it . even if the weld breaks around the shaft it sill works to keep everything together like a pin

That makes sense. I think dad and I are gonna set it up in the CNC and mill a hole in the end of it and then press a pin in there and then tig weld the end of the pin and the main shaft and the impeller together. and then do the same on the gear side. Maybe that will help hold it together :thumb: