Help: LB7 new head studs and cups but still have water leak

- Thread starter SonicAudio

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

you need to stop driving the truck till you get this figured out

a good idea would be to test it with a cold motor then run it to operating temps then test it again if it leaks down cold then you probably wont need to test it hot

a good idea would be to test it with a cold motor then run it to operating temps then test it again if it leaks down cold then you probably wont need to test it hot

Last edited:

So to get by with one time you should tq them to 150 :spit:

There is no one time and skip to 150 there 125 for standard arp studs. The studs that are 150 max tq are aged 625 arps that cost alot more money.

If the thread starter only tq the heads up to the 125 in the set step once then most Likely the head gaskets need replaced and the head studs need to be streached to get the head seated. I do not see a injector cup leaking that much but anything can happen. I also like to use some of the loctite around the 2nd o ring on the injector cup along with it on the tip area. Also do not clean the head or block surface with anything to abrasive it can also cause the gasket to not seal.

pressure test leaked coolant to the front passenger cylinder.

I hate to hear that

new set of gaskets on the way from merchant, and a new head guy that that is familiar with the Duramax. will keep everyone informed as it goes.

We have never done the three torque to 125 three times then set overnite on our engines. We do the sequenc as stated to 125 and let set over nite and then loosen and retorque the next day. We've never had a problem but what ripm666 describes as his procedure can't be a bad thing, that is for sure, just not sure you need to do that much retorquing on the first day, especially on a motor not running that much power.

We have never done the three torque to 125 three times then set overnite on our engines. We do the sequenc as stated to 125 and let set over nite and then loosen and retorque the next day. We've never had a problem but what ripm666 describes as his procedure can't be a bad thing, that is for sure, just not sure you need to do that much retorquing on the first day, especially on a motor not running that much power.

Ken thats how Guy told us to do them.And I think the paper in the arp box said you had to do three times to 125 on the first time use new out of box to streach them also think a few others do it this way. Better safe then sorry also I did not want to retq mine in the truck lol.

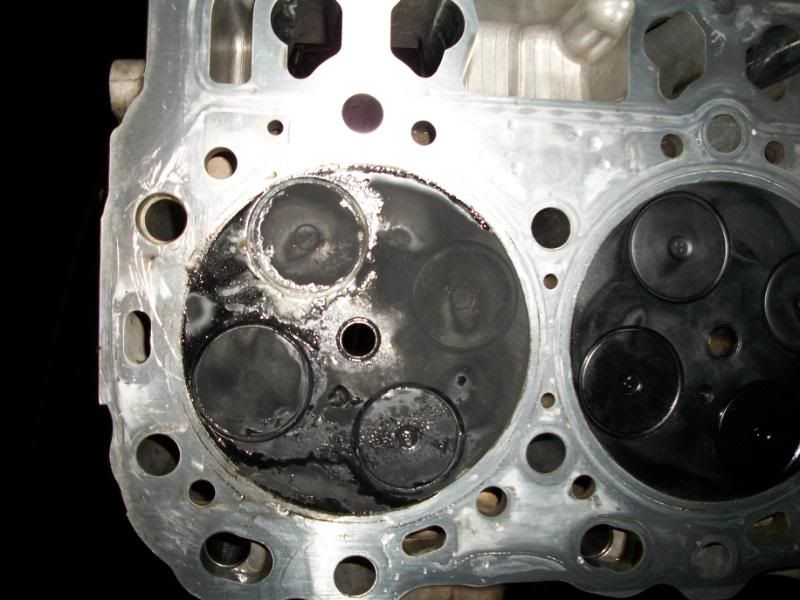

Mine wasent a torque issue at all, checked each one before removing and all were still at 125 on the button even after running! Haven't had the head to the shop yet but as you can see on the 3rd picture down, the valve on the first cylender was weeping water in, gaskets were fine, with no deposits on eather the head nor block of

the coating of the gasket. Crossing my fingers that the valve guide wa installed wrong or it will mean I need a new head.

the coating of the gasket. Crossing my fingers that the valve guide wa installed wrong or it will mean I need a new head.

Not sure if its just camera reflection or what but the back cylinder valves look to have coolant around them also and the headbolt hole in the gasket itself close to top front looks like it has some issues as well.

Last edited:

That was my over use of locktight and red grease I coated the cylenders with on the back valves . That wiped right off with a little smearing with a towl. Also I didn't put the anti-freze in it, it was just distilled water untill I knew It was good to go.

That was my over use of locktight and red grease I coated the cylenders with on the back valves . That wiped right off with a little smearing with a towl. Also I didn't put the anti-freze in it, it was just distilled water untill I knew It was good to go.

OK damn it I've tried to kill that damn bug on my screen twice now.

The head passed the presure test, it held 70 psi for 40 minutes, said that the cylender that was leaking had to be ground down .002 (that minor amount could have been from the removal) he wanted to see the gasket that came off. I will post info as I have it.

Well, magna-fluxed the block, and got the head back from the new machinist, He studied the head gasket also for 30 min with a magnifying glass looking for where the water was leaking. found NOTHING. I then sanded the block and cleaned. cleaned the head studs and added the ARP lube to the threads and the nuts, installed and torqued as stated in first post, got it all together, and still have a leak like i never touched it!

this beats me I have no idea from this point as to what it is.

this beats me I have no idea from this point as to what it is.

Well, magna-fluxed the block, and got the head back from the new machinist, He studied the head gasket also for 30 min with a magnifying glass looking for where the water was leaking. found NOTHING. I then sanded the block and cleaned. cleaned the head studs and added the ARP lube to the threads and the nuts, installed and torqued as stated in first post, got it all together, and still have a leak like i never touched it!this beats me I have no idea from this point as to what it is.

Is it leaking in the same cylinder as before?

Sorry on the numbers,, it was two one hundred thousands of a inch off on the #1.

On the first tear down I put in all new injectors, new cups, all new seals, an sealed with the red lock tight, then inserted the injectors and torqued before moving on to the next cup. But this head was presure tested at 70 PSI and had no leaks and held the presure for 45 min or so with no leak down. As far as the intake, it was dry. I drove I today ( frusterated with this being a recuring issue and just tired of my truck just sitting for a month waiting on mchn shop and money to repair) but after fillin with water ( dextron to expensive till I know I have th leak fixed and yes I am useing distilled water only) ran today on interstate and it never lost water when running. I will know tomorrow if it leaks over night as tha seems to be when it is at it's worst is when sitting.

On the first tear down I put in all new injectors, new cups, all new seals, an sealed with the red lock tight, then inserted the injectors and torqued before moving on to the next cup. But this head was presure tested at 70 PSI and had no leaks and held the presure for 45 min or so with no leak down. As far as the intake, it was dry. I drove I today ( frusterated with this being a recuring issue and just tired of my truck just sitting for a month waiting on mchn shop and money to repair) but after fillin with water ( dextron to expensive till I know I have th leak fixed and yes I am useing distilled water only) ran today on interstate and it never lost water when running. I will know tomorrow if it leaks over night as tha seems to be when it is at it's worst is when sitting.

I'm no machinist, but I didn't know you could pressure test a head without the injector cups installed??