Sorry if this seems a bit sparatic in my description but i am at my whits end and on this project for a little over 4 weeks off and on with VERY little sleep.

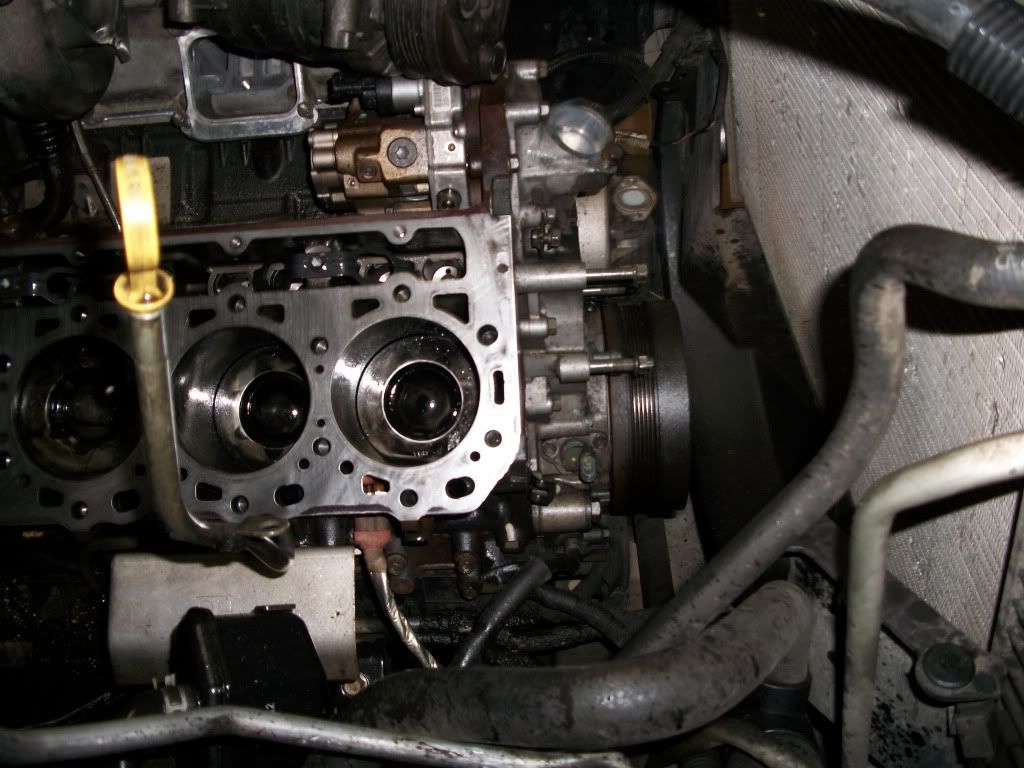

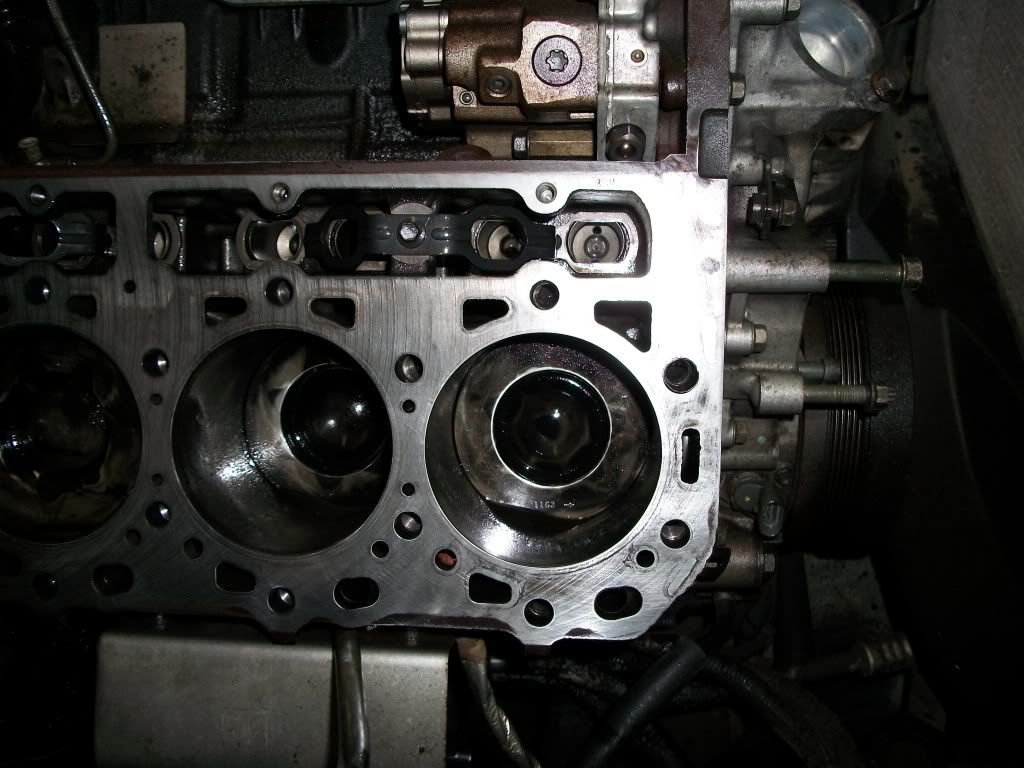

I have had a leak of water to oil and hydro locking when starting my truck. It got to the point i decided to just do it and do it right. I ordered the head gasket kit from merchant that had the ARP studs and head gasket, I also ordered all 8 injector cups (didnt want to do this again). when i removed the heads the right side (passenger) back 2 were full of coolant. I had the heads machined and pressure tested (with no cups as mine had not came in yet). WD-40 1000 grit sanded the block untill it had a almost mirror finish. cleaned the injector cup holes with the kent moore bore tool and HUGE Q-tip. used a TON of the red locktight that came with the gasket kit on the bottom of the injector cups, and installed all new OEM injectors to seat the cups. put back together torqued to 125 in the proper order. I went to work (heard the cups need a 24 hour cure time with the locktight so i wasent going to risk it and fill and run before) placed all back together and fired it up, changed the oil and filter 4 times to get the coolant that was in it out of the block and ports. I have drove it for 2 days, and also let idol for hours during the flush process. I have pictures of the entire process if it will help let me know.

torqued the nuts to 125 in 4 steps.

step 1 - 37lb

step 2 - 59lb

step 3 - 92lb

step 4 - 125lb

i have had the truck for over a year as a daily driver. never a water leak untill just recently and my lower end is stock. and my PPE was never set over level 3 (dont have the money for the allison). the turbo has the PPE increase valve in it ( the blue one).

thing is no over pressure or over heating issue. mater of fact it still is running the exact same temp as before. Also it isnt "loosing" coolant as long as it is running. it seems to only leak into the cyl if it is just sitting not running. That is why i was thinking maybe there was some way the turbo could leak to the intake while not running but that would be in all of the chambers insted of the one. beats me I just dont know...

Now I noticed it hydro locking again and slight water loss (havent filled with the dex-cool yet) I am at a loss here, no idea where to start or what it could be.

Thanks for any help

I have had a leak of water to oil and hydro locking when starting my truck. It got to the point i decided to just do it and do it right. I ordered the head gasket kit from merchant that had the ARP studs and head gasket, I also ordered all 8 injector cups (didnt want to do this again). when i removed the heads the right side (passenger) back 2 were full of coolant. I had the heads machined and pressure tested (with no cups as mine had not came in yet). WD-40 1000 grit sanded the block untill it had a almost mirror finish. cleaned the injector cup holes with the kent moore bore tool and HUGE Q-tip. used a TON of the red locktight that came with the gasket kit on the bottom of the injector cups, and installed all new OEM injectors to seat the cups. put back together torqued to 125 in the proper order. I went to work (heard the cups need a 24 hour cure time with the locktight so i wasent going to risk it and fill and run before) placed all back together and fired it up, changed the oil and filter 4 times to get the coolant that was in it out of the block and ports. I have drove it for 2 days, and also let idol for hours during the flush process. I have pictures of the entire process if it will help let me know.

torqued the nuts to 125 in 4 steps.

step 1 - 37lb

step 2 - 59lb

step 3 - 92lb

step 4 - 125lb

i have had the truck for over a year as a daily driver. never a water leak untill just recently and my lower end is stock. and my PPE was never set over level 3 (dont have the money for the allison). the turbo has the PPE increase valve in it ( the blue one).

thing is no over pressure or over heating issue. mater of fact it still is running the exact same temp as before. Also it isnt "loosing" coolant as long as it is running. it seems to only leak into the cyl if it is just sitting not running. That is why i was thinking maybe there was some way the turbo could leak to the intake while not running but that would be in all of the chambers insted of the one. beats me I just dont know...

Now I noticed it hydro locking again and slight water loss (havent filled with the dex-cool yet) I am at a loss here, no idea where to start or what it could be.

Thanks for any help