what a relief. Yeah I know I got to adjust the valves. (.011) is what I am reading from everyone. ARP's was a no brainer. :thumb: I am not sure about the torque specs though.DO I torque them down to 125f/lbs and then loosen. And do this 3 times? please help. Also since I am "in there" any recommendations on the CP3 fuel pump?

I have already swallowed purchasing new injectors. the ones I took out looked like A$$! Having the turbo rebuilt and a WW2 installed with 360degree thrust bearing.

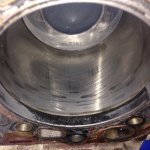

What are recommendations on prepping the block surface?

Tq to 125ft/lbs 3 times. Go to tq, then loosen, re tq. Repeat 3 times.

![20150104_190015[1].jpg](/forum/data/attachments/20/20382-a614d4350a7638c1b74a9e94d2a8e2f7.jpg)

![20150104_194550[1].jpg](/forum/data/attachments/20/20389-72320367ea5822124aa3106a95c0737b.jpg)

![20150106_191121[1].jpg](/forum/data/attachments/20/20400-c580c14d952b2b626711e26615fc0304.jpg)