Ultimately, all the fuel must pass through the FCA. The FCA pulls its fuel from the body of the pump where the rotating assembly, cam and roller reside. When the pump desides its had enough and commits suicide, all of the metal debris must pass though the FCA before making its way to the piston and then to the injectors. As it sits the screen on the FCA is the last resort to stop anything from making its way to the injectors. At 60 microns its more of a sand trap. 25 microns is better but no ware near enough to protect the injectors from harm.........

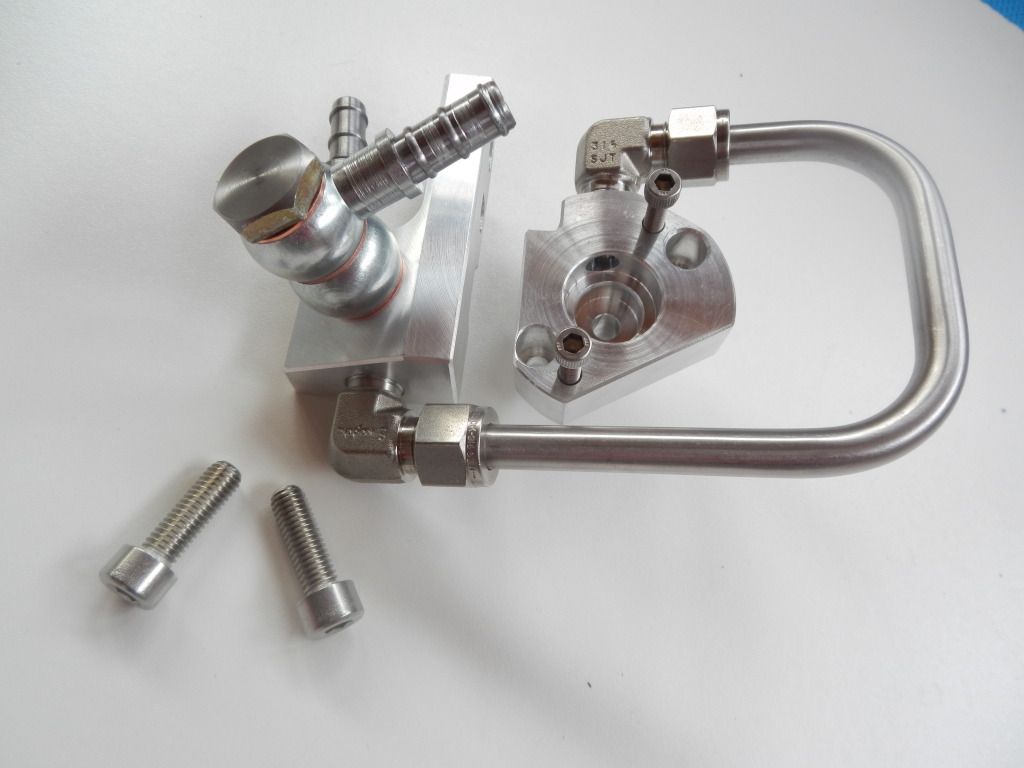

.........2micron makes a bypass kit for the VWs that would likely fit these trucks. It allows fuel to be fed directly into the FCA without going through the body of the pump. Now your main filter is the one that determines what micron size particles make it to the injectors

I think that the hope is the 20 micron might get plugged enough to throw low rail pressure codes causing you to shut down and investigate instead of blowing the bigger pieces into the pumps pistons and injectors scattering the piston section and scrubbing the injectors.

Been thinking of putting one of these FCA deals in my truck as I have no desire to change to a cp3 but I’m intrigued by this vw bypass kit. Wondering if anyone has looked into it further or tried to make it work?

Also has anyone that’s installed one of these had a pump failure that saved injectors?