My wife and I like watching that "forged in fire" show. Takes lots of skill to make a good knife. It is a skill I do not have. :hehe:

Anyone play with making knives or hatchets??

- Thread starter RickDLance

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A lot of guys around here come by and pickup an edger saw that is wore down and make knives. I could save you a few if you would like and send them to you.

My wife and I like watching that "forged in fire" show. Takes lots of skill to make a good knife. It is a skill I do not have. :hehe:

No skill nor equipment for forging so all stock removal for me. takes time to develop the muscle memory and skills to grind out good bevels. Still learning

So, my precut branches from my yard trees are all split and cracking. Probably should have cut them into oversized boards to assist in the drying. If I try and cut more it will be a long time before they are dry enough to use. Oh well

May stop at cabinet maker near by to see if they have any suitable scraps.

Also, for the large chopper, I'm thinking of trying out some horse stall mats / rubber for the handles. Supposed to be super grippie even when wet, sweety, blood or oils. Would be an easy one to try as I have a few mats already.

If it turns out good I may use it on the 2nd (skinner style) knife too. (I may gift it to my uncle as he regularly bow hunts elk, so it would work well as a skinning knife for him). If not then it shouldn't be too much trouble to grind off and put micarta or wood on

May stop at cabinet maker near by to see if they have any suitable scraps.

Also, for the large chopper, I'm thinking of trying out some horse stall mats / rubber for the handles. Supposed to be super grippie even when wet, sweety, blood or oils. Would be an easy one to try as I have a few mats already.

If it turns out good I may use it on the 2nd (skinner style) knife too. (I may gift it to my uncle as he regularly bow hunts elk, so it would work well as a skinning knife for him). If not then it shouldn't be too much trouble to grind off and put micarta or wood on

Hitachi Ats-34 used to be the high tech choice but now any of the crucible S**V steels are what I use. S35VN Current favorite.

That being said any tool steel, can work out well. Or an annealed file. have fun embellishing handles, make it art.

Imperfections turn to flaws, turn to failures, when stressed.

That being said any tool steel, can work out well. Or an annealed file. have fun embellishing handles, make it art.

Imperfections turn to flaws, turn to failures, when stressed.

Yes, s35vn is quite good but seems most can't tell the difference between that and s30v. But you can't really go wrong with either

I've played with files before. Good starting steel. However many newer files are sometimes a mistry steel. Hopefully its 1095 but you never know, so you may not get the best from the steel when heat treating it. Good for practice though

I've played with files before. Good starting steel. However many newer files are sometimes a mistry steel. Hopefully its 1095 but you never know, so you may not get the best from the steel when heat treating it. Good for practice though

Micarta is great for scales, you can get paper, linen, canvas for any texture you want.

Excellent grip in most conditions.

550 chord if someone needs that effect. Leather/wood for older styles.

I used what i could find when i started, now i buy what i intend to use.(snob alert)

Also good source for steel is leaf springs... the kukri is properly made of Mercedes truck springs i believe.

Excellent grip in most conditions.

550 chord if someone needs that effect. Leather/wood for older styles.

I used what i could find when i started, now i buy what i intend to use.(snob alert)

Also good source for steel is leaf springs... the kukri is properly made of Mercedes truck springs i believe.

ok, more progress

about 90% done. need to add pins, finish shaping the handle, some finish sanding, make a sheath and put an edge on it

I used the horse stall mats on this. I really like how it feels in the hand. kind of soft and firm at the same time. grippy even when wet. not the easiest to hand sand but not to hard.

I put an aluminium bolster on it too. I think it really helps to take it to the next level. first one for me

about 90% done. need to add pins, finish shaping the handle, some finish sanding, make a sheath and put an edge on it

I used the horse stall mats on this. I really like how it feels in the hand. kind of soft and firm at the same time. grippy even when wet. not the easiest to hand sand but not to hard.

I put an aluminium bolster on it too. I think it really helps to take it to the next level. first one for me

Those are awesome looking knives! Have you ever considered selling them?

Thanks. I haven't really put much thought into selling any. They are nowhere close, in my opinion, to typical custom or production quality. At least in fit and finish. There are many small flaws that I am still working on getting out in by knifes. Photos don't really show them. Plus I am way behind on sheath making skills too

These last set of knifes are probably the best one's I have made so far but I would need to improve a bit more to make them worth selling. I only do this once every six months or so, so progress would be slow.

I am open to making them for friends and family right now but not really on the open market

all of mine are stock removal. I don't think I'd stand much chance in Forged in fireApplied to Forged by Fire yet?

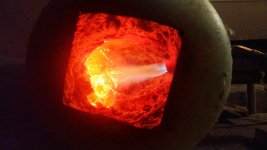

so while we where out hiking our burned property from the Caldor fire we found an old rusty file inside a burned tree. decided it needed a second life at being a knife. hydrochloric acid to remove the rust, reheat treat it in my mini forge as it had gone a little soft from being in the fire. I was able to make two little identical knives. I left the original file teeth to keep the caricature it had while it was living in the forest and battling a fire

Last edited: