The main reason I developed this is for that reason. Typical misting strategy is to spray single nozzle coarse mist, across the conduit. That just agglomerates and turns into a stream on the opposite wall of the conduit, a river that kills the leading edge of the blades.

This is 8 smaller nozzles, much smaller droplet size, airstream entrained fog, which will not hurt the blades.

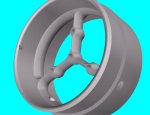

This design has been 2 years in the making. The original was a single nozzle located in front of the compressor. This evolved a lot. The latest challenge was making it un-restrictive to 1000 cfm airflow on CFD analysis.

The tractor puller I know that tried the pre turbo was not run of the mill 150 - 200 psi. This tractor uses engine driven 1000psi set up. He has nozzles in the heads for each cylinder. He also put a nozzle .015 (IIRC) 4" in front of the turbo comp wheel. On the dyno it gained power just switching from the 6 in the heads to the 6 in the heads plus the pre turbo. A good bit of HP to. But he decided to remove the pre turbo after seeing what it did to the wheel. He was worried that Turbonectics would not honor their warranty of that turbo if he hurt it later. Their warranty does not cover FOD which water is considered.

Think about this. Say you have a turbo with a 2.5 inducer comp wheel. If it is spinning at 100,000rpm which are turbos are capable of. At the outer edge of the inducer diameter the surface is traveling a 65445 feet per min (744mph)! At that speed anything it hits is far from soft. If there is any fog it will not be soft.

Not trying to flame you Michael. Just sharing what I know and have seen.