So I had a Quest brake controller installed when I started hot shotting. Since day one, my trailer brakes have not been very strong even with the controller turned all the way up, everyone tells me you should be to easily stop the truck from idling forward with just the trailer brake controller test button which I cannot do. Multiple people have also mentioned locking up/squaling the trailer tires with the trailer brakes. Mine wouldn't dream of doing that... Me and a buddy checked the pads and tightened them up since they are adjustable. Still about the same.. anyone have any ideas? I'm sure it's simple this is just kinda my first rodeo with trailer brakes.

Trailer Brakes Too Weak

- Thread starter OleBlackyLBZ

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

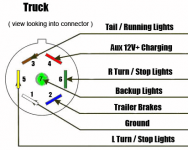

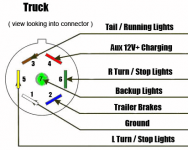

unplug the trailer and have the truck running, with the manual brake controller depressed (as if you are just grabbing trailer brakes only), check voltage at the plug at the back. you dont want a big voltage drop and it happes over time with corrosion. should be around 13v.

if thats all good, get under the trailer and start looking at all the scotch locks they use to connect wires and take them out/change to a sealed butt connector. clean up any corrsion at the ground or other connections as well. the brake wire may also be undersized and causing a voltage drop. wont hurt to see what kind of amps the mags pull at full voltage and upsize the main brake wire if needed.

if all thats good, id look at what magnets are on there, might be undersized for the axles. its possible to put the wrong ones on. Id also make sure there is ) grease on the magnet, in the drum or on the shoes. if it even looks like there was at one time (you have no idea how many guys use the ez lube on the end of the spindle and then blow it all into the brakes), its going to reduce braking. I went through that on my toyhauler cause every precheck as it was built or moved, they pumped grease in and blew it all into the drums.

now by all means, my axles are 7k axles (dual axle on the toyhauler). empty, it wont lock up the brakes but the trailer weighs 12k empty. when you hit the brakes, you feel them hit and slow you down. when i put the tracker in there, its now 14k on the axles and 2k on my pin and braking is greatly reduced. it will still slow me down a hill if i grab them but nothing substantial.

if thats all good, get under the trailer and start looking at all the scotch locks they use to connect wires and take them out/change to a sealed butt connector. clean up any corrsion at the ground or other connections as well. the brake wire may also be undersized and causing a voltage drop. wont hurt to see what kind of amps the mags pull at full voltage and upsize the main brake wire if needed.

if all thats good, id look at what magnets are on there, might be undersized for the axles. its possible to put the wrong ones on. Id also make sure there is ) grease on the magnet, in the drum or on the shoes. if it even looks like there was at one time (you have no idea how many guys use the ez lube on the end of the spindle and then blow it all into the brakes), its going to reduce braking. I went through that on my toyhauler cause every precheck as it was built or moved, they pumped grease in and blew it all into the drums.

now by all means, my axles are 7k axles (dual axle on the toyhauler). empty, it wont lock up the brakes but the trailer weighs 12k empty. when you hit the brakes, you feel them hit and slow you down. when i put the tracker in there, its now 14k on the axles and 2k on my pin and braking is greatly reduced. it will still slow me down a hill if i grab them but nothing substantial.

A simple thing to check is your grounds. Both truck side of the 7 pin (the #1 blade) and the trailer side. Apply your truck brakes with the trailer lights on and see if the trailer lights go out or dim when the trailer brakes are applied. If your lights go dim or out when the trailer brakes are applied then you have a weak ground in the system. Dean

Places that sell trailers, like general utility trailers, have a variety of trailer electric brake magnets. See if they have magnets with more stopping power than your existing units but that will fit and function without any modification. Very easy replacement and great results. James is correct - the connection between the trailer wiring and the brake magnets often is the cause of poor braking performance.

Did you remove the drum and check the brakes?

Do you have through axle grease zerks?

As mentioned, test each magnet using a compass to ensure they are activating. Also double check the axle grounds.

On the first one, if you have not removed the drum to check the brakes, start there as there have been known issues in the camping area of the internal oil seal coming out and greasing the brakes.

On the second, STOP using the zerk. Using the zerk can lead to issue 1 as the internal seal may not have enough seating pressure to prevent it from coming loose.

One other thing is to check the wiring into the brake controller. Are the Positive, Negative, and Blue wires all of large enough gauge? Verify that the connectors used to hook between the controller and the factory wiring is well made. Butt connectors should have the wire seated all the way to the divider and be crimped to secure the wire. I have changed to seamless connectors b/c the ones with the split have given me issues b/c people do not pay attention to where they crimp (also started using non insulated and heat shrink). I also almost always use the non insulated crimp area to ensure the connector is properly seated to the wire double crimping both ends next to each other to increase the contact area. Remember all 3 of these wires can carry the same amperage.

Lastly, have someone else with a known good brake controller hook up and check your trailer. On my GN empty, it will lock up the brakes in grass easily with the factory controller (2018). My Prodigy (in my 04 and my 06) would lock up my TT brakes with no issue if there were any rocks on the pavement.

Do you have through axle grease zerks?

As mentioned, test each magnet using a compass to ensure they are activating. Also double check the axle grounds.

On the first one, if you have not removed the drum to check the brakes, start there as there have been known issues in the camping area of the internal oil seal coming out and greasing the brakes.

On the second, STOP using the zerk. Using the zerk can lead to issue 1 as the internal seal may not have enough seating pressure to prevent it from coming loose.

One other thing is to check the wiring into the brake controller. Are the Positive, Negative, and Blue wires all of large enough gauge? Verify that the connectors used to hook between the controller and the factory wiring is well made. Butt connectors should have the wire seated all the way to the divider and be crimped to secure the wire. I have changed to seamless connectors b/c the ones with the split have given me issues b/c people do not pay attention to where they crimp (also started using non insulated and heat shrink). I also almost always use the non insulated crimp area to ensure the connector is properly seated to the wire double crimping both ends next to each other to increase the contact area. Remember all 3 of these wires can carry the same amperage.

Lastly, have someone else with a known good brake controller hook up and check your trailer. On my GN empty, it will lock up the brakes in grass easily with the factory controller (2018). My Prodigy (in my 04 and my 06) would lock up my TT brakes with no issue if there were any rocks on the pavement.

One thing I've done in the past is to have someone manually apply the trailer brakes from the controller (max current setting), then use a clamp-on DC current meter (~$50 on Amazon) to verify proper current is getting to each brake of the trailer. Measure down at each wheel where the brake wire enters. There are 2 wires per wheel - measure either one. Dexter Axle (one of the most common) says their brakes draw about 3 amps @12v. If the current looks good, then start looking at mechanical issues as mentioned above.

So we checked the wiring last night, 13v at the plug like it should be. Cheap connectors were all used the rest of the way back of course(Will try to upgrade those eventually along with new wiring). We had about 8.5 volts to each brake assembly, assuming you lose some running back that far? I know almost nothing about electrical so I had a friend help me test everything.unplug the trailer and have the truck running, with the manual brake controller depressed (as if you are just grabbing trailer brakes only), check voltage at the plug at the back. you dont want a big voltage drop and it happes over time with corrosion. should be around 13v.

if thats all good, get under the trailer and start looking at all the scotch locks they use to connect wires and take them out/change to a sealed butt connector. clean up any corrsion at the ground or other connections as well. the brake wire may also be undersized and causing a voltage drop. wont hurt to see what kind of amps the mags pull at full voltage and upsize the main brake wire if needed.

if all thats good, id look at what magnets are on there, might be undersized for the axles. its possible to put the wrong ones on. Id also make sure there is ) grease on the magnet, in the drum or on the shoes. if it even looks like there was at one time (you have no idea how many guys use the ez lube on the end of the spindle and then blow it all into the brakes), its going to reduce braking. I went through that on my toyhauler cause every precheck as it was built or moved, they pumped grease in and blew it all into the drums.

now by all means, my axles are 7k axles (dual axle on the toyhauler). empty, it wont lock up the brakes but the trailer weighs 12k empty. when you hit the brakes, you feel them hit and slow you down. when i put the tracker in there, its now 14k on the axles and 2k on my pin and braking is greatly reduced. it will still slow me down a hill if i grab them but nothing substantial.

I had unknowingly used the ez grease zerks, and I'm sure the guy that had owned the trailer before me used them as well. Pulled one of the tires off last night and there is definitely grease slung up on the pads, it was curled off the edge of the pads but they had definitely been greased good. There was grease on the magnets too.

Do I need to just buy all 4 new brake assemblies at this point or can I just buy new pads, new grease seals, pack the bearings by hand this time, and clean up the magnets and everything real good with brake cleaner?

Last edited:

So we checked the wiring last night, 13v at the plug like it should be. Cheap connectors were all used the rest of the way back of course(Will try to upgrade those eventually along with new wiring). We had about 8.5 volts to each brake assembly, assuming you lose some running back that far? I know almost nothing about electrical so I had a friend help me test everything.

I had unknowingly used the ez grease zerks, and I'm sure the guy that had owned the trailer before me used them as well. Pulled one of the tires off last night and there is definitely grease slung up on the pads, it was curled off the edge of the pads but they had definitely been greased good. There was grease on the magnets too.

Do I need to just buy all 4 new brake assemblies at this point or can I just buy new pads, new grease seals, pack the bearings by hand this time, and clean up the magnets and everything real good with brake cleaner?

it was cheap when i replaced mine to just do it. you can clean the shoes but as they heat up, grease will sweat out of them and can cause smoking or even still give a little lack luster on braking. up to you if you wanna just clean and give it a shot.

you should have far more voltage back at the brakes. it should be MAYBE 11-12v by time you get back there. sounds like there is too much resistance from either too small of wire (typical for trailers) or bad connections.

I'd guess too small of wire as the primary cause. bad connections can do it too but because it's a concentrated heat location it tends to fail or burn up more quickly if dropping that much voltage at that current level. 14 gauge minimum with 12 being more idealit was cheap when i replaced mine to just do it. you can clean the shoes but as they heat up, grease will sweat out of them and can cause smoking or even still give a little lack luster on braking. up to you if you wanna just clean and give it a shot.

you should have far more voltage back at the brakes. it should be MAYBE 11-12v by time you get back there. sounds like there is too much resistance from either too small of wire (typical for trailers) or bad connections.

i think adam ran 12 ga on his old trailer and still saw a 1v drop from plug to mag but he probably ran bigger magnets than the ones we are talking about.I'd guess too small of wire as the primary cause. bad connections can do it too but because it's a concentrated heat location it tends to fail or burn up more quickly if dropping that much voltage at that current level. 14 gauge minimum with 12 being more ideal

If you are applying full manual brake application to the trailer you should have vehicle voltage to the trailer. Check this first at the connection at the back of your truck and then at the brake wires. That you look at next will depend on what you find there. As for the brake pads do some checking, some trailer places will show the whole brake assy for about what the pads alone will go for. Personally I have no problem cleaning up the old stuff but price on parts can dictate what you want to do. When replacing the hub seals for the bearings make sure the seals you get have a double seal design. One side to keep grease in and the other to keep everything else out. Basically the internals of the seal will have a V profile. Some cheaper seals will only keep dirt out and this is wrong for an easy lube axle. Dean

1 volt is not bad. certainly better then the 4.5 volts the OP is havingi think adam ran 12 ga on his old trailer and still saw a 1v drop from plug to mag but he probably ran bigger magnets than the ones we are talking about.

lol no kiddin1 volt is not bad. certainly better then the 4.5 volts the OP is having

Thanks guy, sounds like I have at least two issues. We are going to do some more testing tonight and try to find where we are losing the voltage. If I can get that fixed then I will clean up the shoes and magnets etc and see how it does then.

Do your wires run through the axel or on the outside. Some times the wires inside an axel will rub through and cause voltage drop to an outright short. You might try separating the wires right before it hits the first brake and check voltage there. That will eliminate circuit before and after the first magnet.