Is there a problem with making traction bars with square tubing or is there a reason they are done with DOM tubing. I have a set designed for my truck just looking for some info before I fab them up. Thank's

Phil

Phil

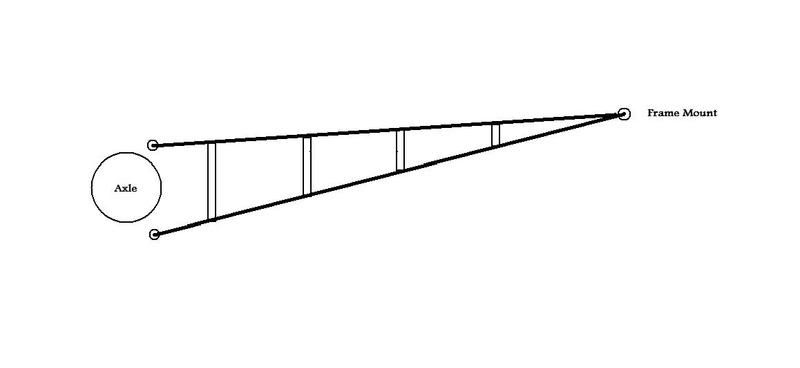

although most people wouldn't want to take the time to build it, the strongest and lightest thing would be latace, like a crane boom. But the external dimensions would be much larger.

:nopic:

although most people wouldn't want to take the time to build it, the strongest and lightest thing would be latace, like a crane boom. But the external dimensions would be much larger.