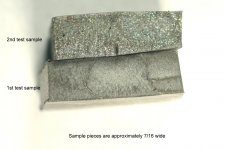

Here are some samples I did when I was adjusting my heat treatment parameters to try and reduce grain structure.

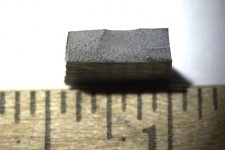

In this photo. The 1st test was a lower austenitizing temperature. I think it was around the 1450° range. The second I believe was about 50° higher and the difference in grain was huge. Temperature plays a huge rule in the quality of the final heat treatment

View attachment 112008

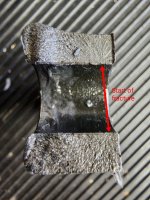

In this sample. I was told the grain was too large to have adequate toughness for knives. And yours I would imagine should have been much tougher then most knife perimeters have. I didn't see anything about what steel was being used and a quick Google search showed that others are using "alloy steel" which could mean anything as all steel is an alloy. Kinda meaningless.

View attachment 112009

If your vendor gives you the finger and you have trouble getting replacements that don't break. I'd be inclined to at least reach out to Larrin Thomas at Knife Steel Nerds to see if he is willing to look at your hold downs and give his opinion. That guy is the smartest guy I know when it comes to metallurgy. He freaken designs his own steels and has the largest breakdown and testing of various steel testing. He is also an active member on the blade forums so he is always giving out information for free and helping others