I was going to just update the other thread but figured I would start a new one for oil coolers.

Condensed version of the oil cooler talk in the other thread.

Summit Racing was out of stock on the Fluidyne DB-30617 cooler and originally showed a ship date of 4-15 or something like that. They kept pushing the date back and it is now at 05-25. Since I am getting close to building and installing the motor I wanted to get one sooner. I called all my normal sources and no one had one in a warehouse. Found one at HRPWorld.com and someone bought it while I was trying to order it. I then started calling all of the Fluidyne dealers on their site and finally found one that had it. www.theboombopshop.com for $380 shipped. Just keeping everyone up to date. When I get it installed I will post what temps I see.

Condensed version of the oil cooler talk in the other thread.

Maybe it is engine oil temperature more than egts. Are egt's fine if the cool oil keeps cooling the piston then when the oil gets hot and provides insufficient cooling then egt's play a factor? Fact: Pistons and cylinders are heat generators. Egts are only one source of measuring heat. Engine oil temperature gives the egts a degree or a severeity level. So if you keep egt's in check, then engine oil temps stay in check. Do briefly and extremely high egt's make little difference when oil temps stay cool? Egt's over time do the damage. I think egt's are only severe if given time, kind of like the difference between a 3rd degree burn and a 1st degree burn. Both do their damage. If you get enough third degree events then will you eventually end up with 1st deg consequence?

You are running your gauge pre-cooler. What was your reason for putting it there? You are also running an external cooler, correct? If you had your gauge before you added the cooler, what kind of benefits did you see from it?

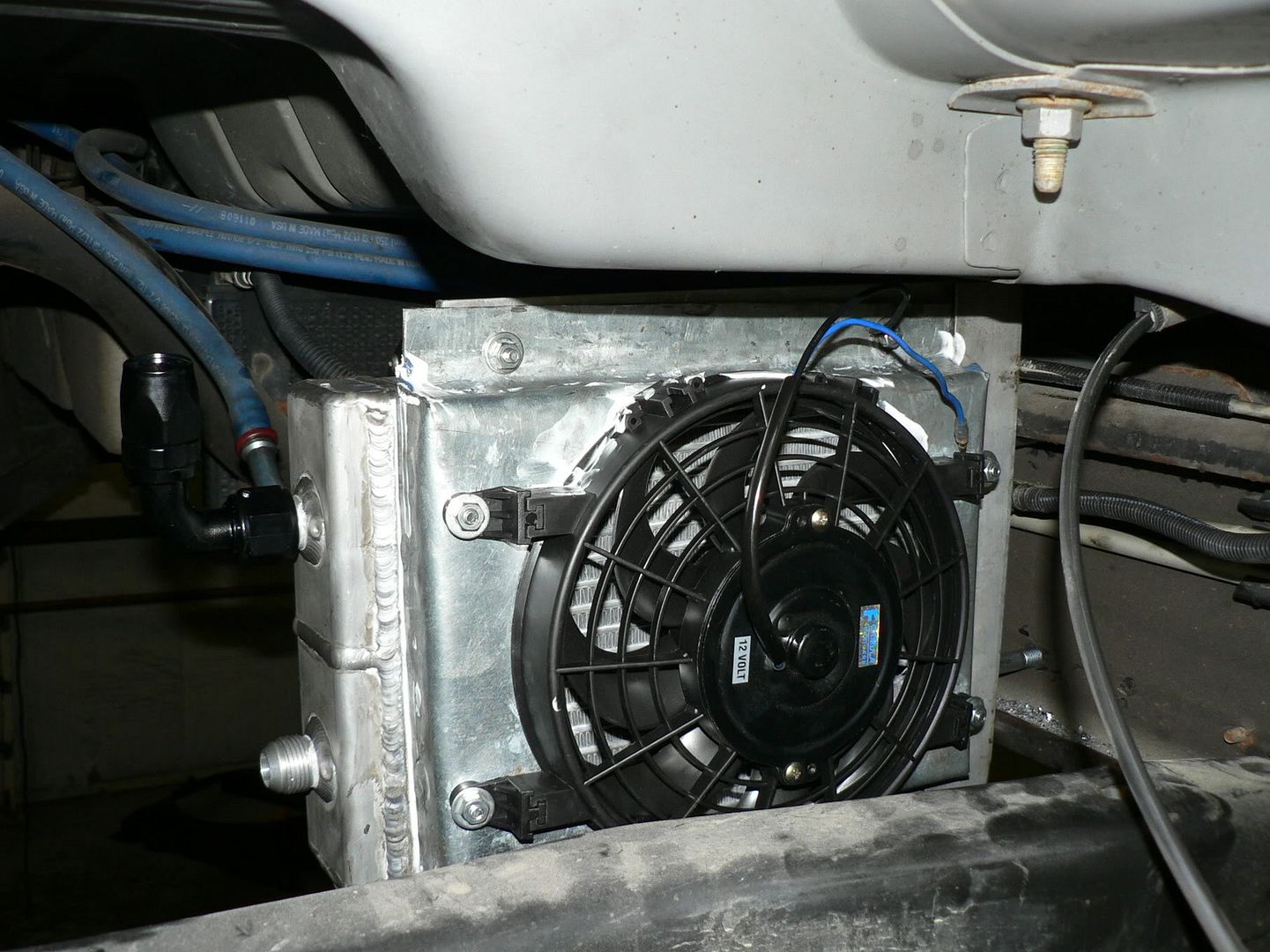

I installed my guage before I had the cooler. I would see average temps of 220+ just cruising around town. Put a small load behind it (or a bit of racing) and it would easily be 250+. When I decided to install the HTT I wanted some safety, being that it's only cooling is from oil, so I got the oil cooler too. Now my average around town temps are usually under 200, and even with my 37' toyhauler in tow I have to really work it to reach 240. Normal towing temps are 220ish with ambient temp in the 70s..

One thing that the cooler oil helped is the psi. Even when at operating temps the idle pressure is usually above 30, and hot cruise is above 60.

A side benefit was removing enough heat from the engine to allow me to remove the belt driven fan and run dual Taurus electric fans with out having coolant temp issues while towing.

Whether you want a thermostatic oil filter adapter or a plain adapter you need to know that the nipple for the oil filter is 13/16" x 16 thread and the o-ring seating area is 3.5" diameter.

Just ordered everything for my oil cooler:

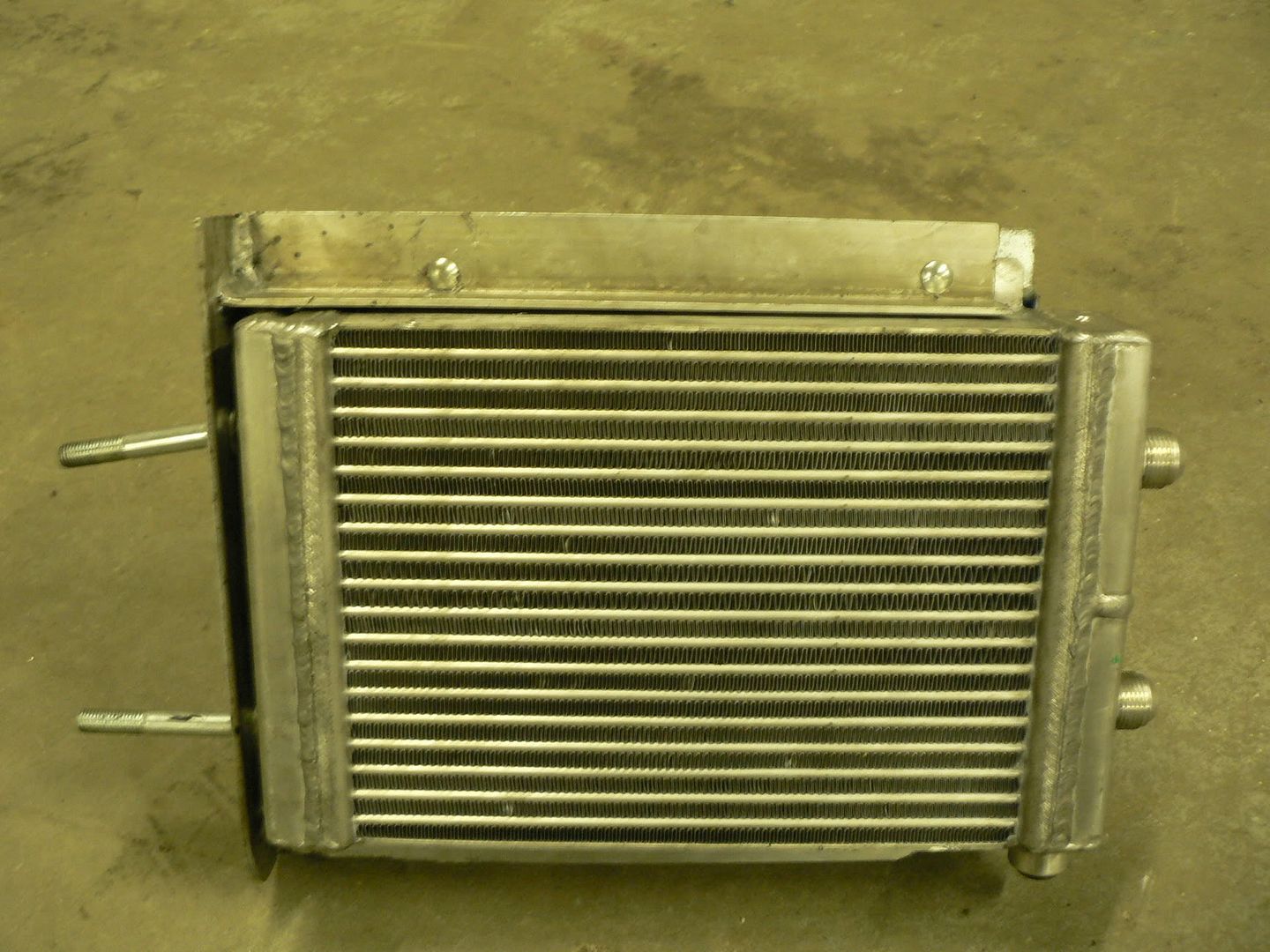

Oil Cooler - make Summit price match CarShopInc.com

Oil Filter Mount - won't take a Duramax filter but I'll just get a filter that fits it.

4 - 1/2NPT to -12AN fittings for the adapter at the motor and the filter mount

4 - -12AN hose ends for the adapter and filter mount

2 - 90* -12AN hose fittings for at the oil cooler

10 ft of braided nylon 350PSI -12AN line

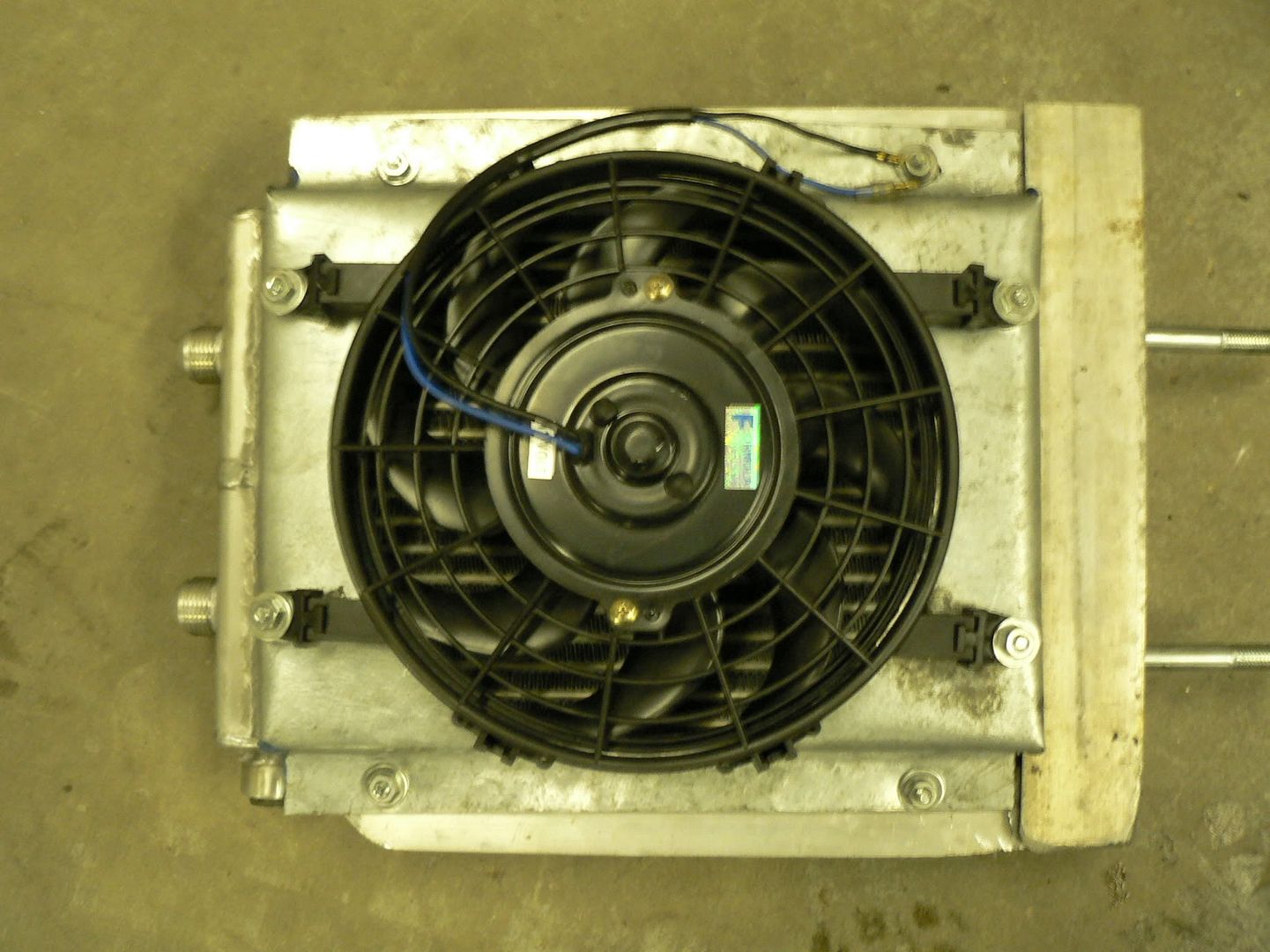

10" 1000 CFM electric fan - picked it up at their booth at a swap meet this weekend

Total with shipping and all was under $600. I'll wire the fan to a switch beside my oil temp gauge (what used to be my trans temp gauge) so that it's only on when I want it to be. You could also use a thermal fan switch to do it for you.

I like this setup more for me because the truck doesn't have to be moving to push air through the cooler and after a pass down the track I can sit in the pits with the truck idling and the fan on. I'll let you know what I see for temps.

Summit Racing was out of stock on the Fluidyne DB-30617 cooler and originally showed a ship date of 4-15 or something like that. They kept pushing the date back and it is now at 05-25. Since I am getting close to building and installing the motor I wanted to get one sooner. I called all my normal sources and no one had one in a warehouse. Found one at HRPWorld.com and someone bought it while I was trying to order it. I then started calling all of the Fluidyne dealers on their site and finally found one that had it. www.theboombopshop.com for $380 shipped. Just keeping everyone up to date. When I get it installed I will post what temps I see.