I'd definitely balance it. That wheel combo is heavy. Lots of mass flinging around at 100,000+ rpm to be out of balance...

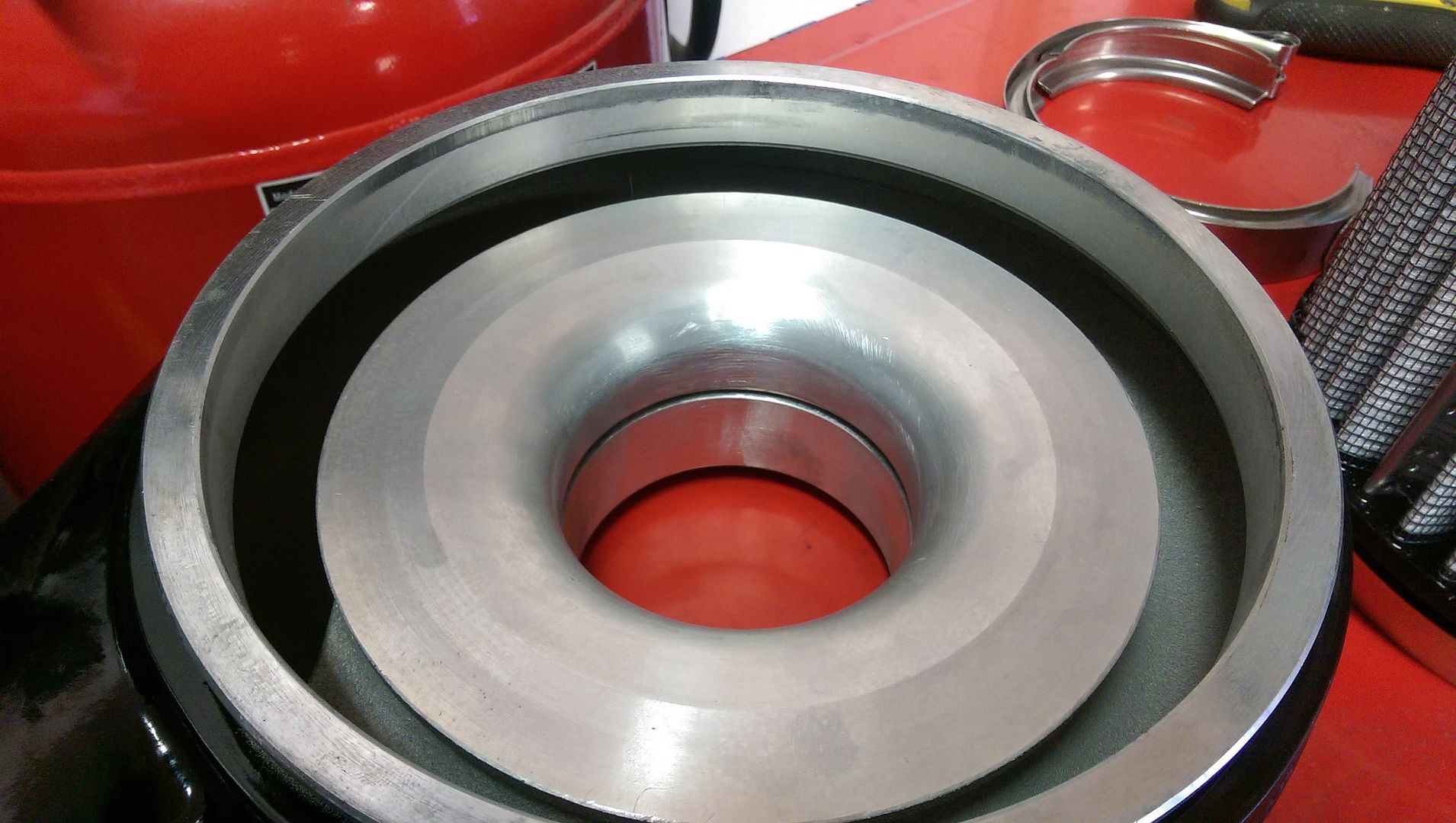

New turbo failed, compressor wheel rubbing housing

- Thread starter thunder550

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

might as well get the housing machined for a 80mm wheel. it looks pretty rough, its not very much money to upgrade and you know it will be fixed rite.

A little lesson here. Always tap all v-band clamps with a small hammer. It sets the clamp and clamped surfaces together. You will always have to re-torque the nut after giving the clamp a tap job. Sucks this happened...

If you buy a take-out comp wheel it should be factory balanced. The turbine shaft and compressor wheel don't have timing marks, so how do you suppose that works.

I would have it balanced and checked just to make sure the shaft is true. Even the slightest bend will destroy it quickly. As others have said it is balanced separately.

James, this is from AGP's web site....have you had them work on a turbo you didn't buy from them before?

If your turbo was not purchased from AGP Turbo, please contact the company you purchased it from. If it did not start off life coming from AGP, we do not want to rebuild it.

James, this is from AGP's web site....have you had them work on a turbo you didn't buy from them before?

Yes ive talked to the owner (ben) and he even put time aside for me to machine my backing plate to upgrade to the 80mm wheel i had a while back. plans changed and i never followed through but ben was very willing to help me out if he could.

you might call them this morning and run it by them first. Unless you work close by to them

So what now? Compressor housing and wheel have to be replaced?

the housing looks ok could probably be polished up, the wheel needs replaced though.

Went and visited Ben, picked up a new wheel. Will clean up the housing when I get home and put it all back together. He said not to worry about balancing. He also took a look at the turbo and said everything else looked fine.

Imagine that, a turbo guy said not to balance it

Weird huh? Apparently the assemblies are not balanced from the factory either. He said he talked to the BW guys at SEMA and they said the components are so close to zero that it would be maybe 1 in 1000 that would need any balancing work, and even then it would be minimal.

I swapped my cast wheel for a billet on my S400. No balancing, ran it for more than 20,000 hard miles and now its a 83 and still going. Not sure if Mark balances them or not but he put my 83 wheel in

The parts are neutral balanced to zero so you can swap them around without issue. Think about it this way, without it being key wayed, how would you keep the wheel and shaft lined up?

A little lesson here. Always tap all v-band clamps with a small hammer. It sets the clamp and clamped surfaces together. You will always have to re-torque the nut after giving the clamp a tap job. Sucks this happened...

I do this all the time when I assemble them:thumb:

As others have said you don't have to balance them being they're component balanced. That way, garrett, IHI, Holset, etc. can have different parts made at different factories then assemble them at there place; safes ALOT of money.

One thing to remember thought, all parts are balanced to a certain tolerance. If you so happen to line those spots up just right, you're assembly would be off even more.

Anymore, I balance all the turbo's I do. Its piece of mind so you don't have to worry. They usually have to removed some material off of the compressor wheel and turbine wheel. More generally has to be removed from the stock turbine wheel than the aftermarket compressor wheel.

Once an assemble is balanced, they will put a mark on the compressor and turbine side that you then have to line up when you reassemble your turbo.

Glad you got it fix and on your way back together.:thumb:

Yellowchevy