New duramax rods iv been working on

- Thread starter Pootrol

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

those prices cant be right though.

Sent from my SM-G900T using Tapatalk

Would be when you send money and they swear they shipped the parts.

In my opinion, one should wait until after the product has been put through its paces privately to post on a forum about a new product as crucial as a connecting rod. I think its great that he is trying to bring something new to the table, but folks will be very reluctant and cautious before hearing how the product performs in a high stress engine. But until that is proven and data is made available, all claims are mere speculation.

Exactly. Get your facts and specs straight before bringing something so big into the market. I've learned you have to research the chit out of companies anymore cause so many con artist in the diesel world now days.

Hi iv just finished these up been 7 months in the making made from a forged billets and best maching stations availible heat treaded shot peened etc come with arp2000 equivalent bolts with material test data sheets etc. if anyones interested in trying some send me a pm

Man this feel's like Deja-vu all over....

alot of design and stress testing went into these to be as good if not better then the top brand rods. not another duramax tuner delema. we had all new tooling made just for the forgings

at the moment ill rate these to 1000 fwhp as thats what we have them at to keep people happy.

As good or better than other top brands???? and only tested on a torque deficient 800rwhp but rating them @ 1000 fwhp????:rofl: Come on now......

im trying to get a few sets out there with any luck there will be some feedback soon. no point just people saying there trash lets just see how they go as stated iv got them in my truck 100 over sticks 12mm cp3 with a big single nearly maxed out and no complaints so far so will get these other 2 motors running and see how they go. and then we wil see from a couple of others who have pm'd me how we go

As another "BIG" single guy (88mm) we ALL know they don't produce the TQ that a twin turbo truck will make. Twin turbo's are considerably harder on parts (especially rods/pistons), then any single turbo will even be. Using that as an example of how strong they are or aren't isn't proving anything....:hello:

Chassis yes.. Engine?

Yes Adam, I have the best engine dyno money can buy! I have a Land & Sea Dual water brake capable of 6,000hp 12,000ftlbs, more than I will ever need but better to have it and not need it than to not have enough and need it!:thumb:

I'll make it easy. There are several reputable diesel based shops out there, all whom own an engine dyno, in house. Pick 4 or 5 and send them a set for free to throw in their mule engine. Let them beat the piss out of your rods for a good while. That is what people want to see.

Exactly.

Ya know, the owner of this very forum does material/parts testing for a living.

Exactly.

Ya know, the owner of this very forum does material/parts testing for a living.

IDK Pat did strength testing? Thought he did dimensional testing - fancy measuring of dimensions on really critical parts?

Either way, yeah, these need a good run through the proper paces to even get on the radar as viable. Hope they turn out to be as good as the OP says he thinks they are. :thumb:

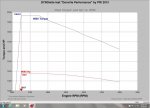

This guy can send me his "built engine" and I will gladly put it up on my engine dyno and put it through the paces and see what he does or doesn't really have to offer and will gladly document it all including the cylinder pressure vs. horsepower. I will continue to add air and fuel until something screams uncle and we can see how these rods fair in the real world applications that we are building engines for our customers! In fact I did a new record last night with single cp3 and single turbo fuel only, Finger's Oval Race cast pistons on my personal built motor that I use for testing parts and combinations. Made 1380hp and 19xxftlbs at 4412psi cylinder pressure. So if you really want to prove what you have for all these guys, send a motor with these rods in it but it better be what you say it is because I don't want to clean up a mess from junk parts! If there is a weak link I will definitely show you where it is!

Attachments

Last edited:

K

That scale says everything. Chinese knock off junk

Also arps are 12pt for rod bolts

That scale says everything. Chinese knock off junk

Also arps are 12pt for rod bolts

for the people that have legitimately pm'd me to test these ill pm you the test data and material data thanks for being willing to try something else out

these rods have really upset a few people. they cant prove them selfs with out anyone testing. iv had all the ndt and stress analysis done and have them in 3 motors so testing is happening

Why not openly share or show the data here? .....the figures you are talking about and others have asked for multiple times is not proprietary info to you/builder/designer/machinist/engineer/etc.

This guy can send me his "built engine" and I will gladly put it up on my engine dyno and put it through the paces and see what he does or doesn't really have to offer and will gladly document it all including the cylinder pressure vs. horsepower. I will continue to add air and fuel until something screams uncle and we can see how these rods fair in the real world applications that we are building engines for our customers! In fact I did a new record last night with single cp3 and single turbo fuel only, Finger's Oval Race cast pistons on my personal built motor that I use for testing parts and combinations. Made 1380hp and 19xxftlbs at 4412psi cylinder pressure. So if you really want to prove what you have for all these guys, send a motor with these rods in it but it better be what you say it is because I don't want to clean up a mess from junk parts! If there is a weak link I will definitely show you where it is!

That's impressive!!! :thumb:

Man this feel's like Deja-vu all over....Where are the pics of the rods with all the pretty colors showing how they will handle the stress??

Who could forget?

Yes Adam, I have the best engine dyno money can buy! I have a Land & Sea Dual water brake capable of 6,000hp 12,000ftlbs, more than I will ever need but better to have it and not need it than to not have enough and need it!:thumb:

Outstanding!! :thumb:

Stellar observations. Especially the rod bolts.K

That scale says everything. Chinese knock off junk

Also arps are 12pt for rod bolts

Too many questions without answers or proof of QC/QA, adequate testing, or willingness to give a few sets away for 3rd party testing for my liking. Or for most who know anything about what it takes to build a high hp/tq dmax.

Not enough posts containing the words program or mainstream to be related to hogie. I'm guessing just a troll trying to make a quick buck. Good thing this site is full of educated dmax folk. Might have saved someone alot of money!

He sent me a PM wanting to purchase the injectors I have for sale and ship them to Australia, I was not willing to risk it....

Not enough posts containing the words program or mainstream to be related to hogie. I'm guessing just a troll trying to make a quick buck. Good thing this site is full of educated dmax folk. Might have saved someone alot of money!

His name is pootrol :roflmao: