I had been thinkin bout this some and prolly the best place for the venturi (most vaccum draw) id say right before your exhaust opens up to bigger size. EX:// I have (for now) my 6" mated to my stock downpipe and chunk of the front pipe. Well where it adapts from 3" to the 6" i have a merge cone conecting the two. Now fast hi-velocity gas moving through the DP emptys into the large volume/lower psi of the 6" and by design will pull a "vaccum" at that area. So ideally IMO i would place the venturi a few inches forward of the transition in the hi-velocity stream. Now there can be psi in the exhaust but by effect of the venturi design, flow past it can still create a vaccum in a psi enviroment, but to maximixe effectiveness, proper placment is needed. So if your exhaust has such a spot in it, might think bout placeing it there. JMHO, since this is uncharted territory. The fact that there is a minor psi present in your PCV system already is good for makin this work. That checkvalve is insurance against pressurizing the crankcase. Hopefully it works so good that a vaccum is created in the crankcase! then you'll reap the benifits of improved ring/gasket sealing! I wish i were there to help! One of the best ways of checking to see that its working is with a slack tube, also called a Manometer (google it). You can buy one or build your own, very simple! We use one at work to diagnose PCV systems all the time, big maker of them is Dwyer, we got ours from Grainger, bout $200 though! If any you guys are intrested, ill make up a drawing and such for a homemade manometer, very handy tool.

Question: How to Route PCv into exaust system ?

- Thread starter slowlmm

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ive always wondered about this on our trucks.

Ive always ran evac systems on my hotrods just welded a couble diverter valves in the headers and ran some heater hose from the valve covers.

On my last engine I even picked up a 2/10ths in the quarter when I installed them.

Keep us posted!

Ive always ran evac systems on my hotrods just welded a couble diverter valves in the headers and ran some heater hose from the valve covers.

On my last engine I even picked up a 2/10ths in the quarter when I installed them.

Keep us posted!

I had been thinkin bout this some and prolly the best place for the venturi (most vaccum draw) id say right before your exhaust opens up to bigger size. EX:// I have (for now) my 6" mated to my stock downpipe and chunk of the front pipe. Well where it adapts from 3" to the 6" i have a merge cone conecting the two. Now fast hi-velocity gas moving through the DP emptys into the large volume/lower psi of the 6" and by design will pull a "vaccum" at that area. So ideally IMO i would place the venturi a few inches forward of the transition in the hi-velocity stream. Now there can be psi in the exhaust but by effect of the venturi design, flow past it can still create a vaccum in a psi enviroment, but to maximixe effectiveness, proper placment is needed. So if your exhaust has such a spot in it, might think bout placeing it there. JMHO, since this is uncharted territory. The fact that there is a minor psi present in your PCV system already is good for makin this work. That checkvalve is insurance against pressurizing the crankcase. Hopefully it works so good that a vaccum is created in the crankcase! then you'll reap the benifits of improved ring/gasket sealing! I wish i were there to help! One of the best ways of checking to see that its working is with a slack tube, also called a Manometer (google it). You can buy one or build your own, very simple! We use one at work to diagnose PCV systems all the time, big maker of them is Dwyer, we got ours from Grainger, bout $200 though! If any you guys are intrested, ill make up a drawing and such for a homemade manometer, very handy tool.

HOly moly batman IM lost LOL. ok well let see my down pipe basicly goes straight to my exaust there is a small radious then contiues on out the back of the truck. so would just at the bottom of the down pipe work or at the bottom of the radius on the exaust or even further down mabey? look slike on the pdf that that may be the equivilant spot on our trucks mabey ? I have always wanted to put some sort of gugae on the pcv as well to test it. is that the manometer dealio you where speaking of ? thanks for the help guys

Drawings

OK 1st one is an example of how i would place the venturi if there is an expantion in exhaust size somewhere in the system. If no expansion in size, place in convienient spot in downpipe.

2nd pic....

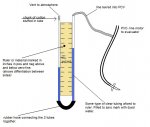

Homemade slack tube manometer!

Need:

clear tubing

measured/marked implement or ruler

some hose

dyed water

cotton (for restrictor)

Tee connector

Now, you'll take 2 equal lenth pieces of clear tube and attach them to the measured center piece. use a piece of hose to connect the tubes at the bottom. now you'll need to tee into the evacuator line with tee connector an hose and hook it to one of the tops of open tubing, dosnt matter which one.

now fill to the zero mark with dyed water. the other end of the clear tube stays open but i would stuff like a piece of loose cotton puff in the end as a restrictor/damper. Now you might want to find a way to rig this to hang from the hood to check @ idle. Now to check under all conditions, you'll need enough hose and a 2nd person to hold it inside the truck and ride with you. Make sure however you temporarilly run the hose that it doesnt get pinched. Also, no blower fan on inside or anything to affect pressure inside the cab. Lemme know if somthins unclear or i missed somthin!

Now shown in that drawing, (zero-line is hard to see, sry) it is pulling 2" of vaccum. The side the meter is hooked to the PCV line, you want the level to raise, (trying to suck water in) up some. It would be fantastic if it actually sucks the water all out, indicating strong vaccum. Should never spit water out open end with a good operating checkvalve!

OK 1st one is an example of how i would place the venturi if there is an expantion in exhaust size somewhere in the system. If no expansion in size, place in convienient spot in downpipe.

2nd pic....

Homemade slack tube manometer!

Need:

clear tubing

measured/marked implement or ruler

some hose

dyed water

cotton (for restrictor)

Tee connector

Now, you'll take 2 equal lenth pieces of clear tube and attach them to the measured center piece. use a piece of hose to connect the tubes at the bottom. now you'll need to tee into the evacuator line with tee connector an hose and hook it to one of the tops of open tubing, dosnt matter which one.

now fill to the zero mark with dyed water. the other end of the clear tube stays open but i would stuff like a piece of loose cotton puff in the end as a restrictor/damper. Now you might want to find a way to rig this to hang from the hood to check @ idle. Now to check under all conditions, you'll need enough hose and a 2nd person to hold it inside the truck and ride with you. Make sure however you temporarilly run the hose that it doesnt get pinched. Also, no blower fan on inside or anything to affect pressure inside the cab. Lemme know if somthins unclear or i missed somthin!

Now shown in that drawing, (zero-line is hard to see, sry) it is pulling 2" of vaccum. The side the meter is hooked to the PCV line, you want the level to raise, (trying to suck water in) up some. It would be fantastic if it actually sucks the water all out, indicating strong vaccum. Should never spit water out open end with a good operating checkvalve!

Attachments

Last edited: