Holes in pistons?

- Thread starter Alligator

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I completely disagree.i think its a good possibility that the squirters could be cooling the piston down to fast .along with the surface pressure in the piston bowels pushing out on them when the cooling process is happening , therefore cracking the pistion in half

?

Lubrication System

9.5 L

8.7 L

14 psi

42 psi

64 psi

29 psi

- Oil Capacity - with Filter

9.5 L

- Oil Capacity - without Filter

8.7 L

- Oil Pressure - Minimum- Hot - at idle

14 psi

- Oil Pressure - Minimum - 1800 RPM

42 psi

- Oil Relief Valve Opening Pressure

64 psi

- Piston Cooling Jet Valve Opening Pressure

29 psi

ok so from what rip has posted after a hard run and back to a idle oil press is around 14 so that means the piston squirters arent even squirting at idle, see theres always a reason why a pistion cracks,like for instance if you had excessive piston to cyl wall distance you would have piston slap and would be cracking the piston skirts, so now i have seen in gas motors ring lands break from too much cylinder pressure from excessive boost and timing.

there has got to be a way to narrow this down to something other than shitty material in the piston, there is always a reason why a piston cracks and the way it cracks means a certain thing , so the more data we can bring to the table to look at the faster this problem can be solved .

does anyone have any data logging that they were doing when the piston let go in there truck?

there has got to be a way to narrow this down to something other than shitty material in the piston, there is always a reason why a piston cracks and the way it cracks means a certain thing , so the more data we can bring to the table to look at the faster this problem can be solved .

does anyone have any data logging that they were doing when the piston let go in there truck?

Last edited:

i think its a good possibility that the squirters could be cooling the piston down to fast .along with the surface pressure in the piston bowels pushing out on them when the cooling process is happening , therefore cracking the pistion in half

?

I see what your saying ,but cant see it cooling to fast as the oil is HOT and has less pressure and less vis

does anyone have the temp of the oil after a hard hard run at idle at the 14 psi?

I would geuss 250+ yet ive never seen a HOT OIL light that comes on at 300f IIRC

Im going to install a temp gauge for the oil on my truck this winter and start taking more note of it

ok so i found an article on the net and this is what i said about the pressure in the bowel causing the crack so this article says the same thing about extreem pressures in the piston bowels causing cracks in high hp application diesel engines like the duramax

Under Pressure

The pistons in a diesel engine must also withstand significantly higher compression pressures and operating temperatures than those in a gasoline engine. Because of this, the top piston ring runs hot. To reduce top ring pound out, most stock diesel pistons have a steel or iron insert for the top ring groove. This greatly improves the durability of the piston, and also allows the use of a keystone-shaped top ring to minimize ring sticking.

Because the pistons need a top ring groove insert for durability, the pistons must be cast rather than forged. Most use an alloy that contains 11 to 13 percent silicon so the pistons will have some ductility. To date, hypereutectic alloys with higher silicon levels have not been used for diesel pistons.

In heavy-duty high output engines, two-piece “articulated” pistons with steel crowns and aluminum skirts are often used for improved durability. The wrist pin holds the two pieces together, and allows the piston to handle higher loads than would be possible with a one-piece cast piston. Some engines also use a one-piece all-steel piston such as Mahle’s “Monotherm” piston or Federal Mogul’s “Monosteel” piston. The steel pistons are extremely durable and can handle the highest loads, but also tend to be heavy and expensive, costing up to three times as much as conventional cast aluminum pistons.

In recent years, diesel pistons with ceramic fiber reinforcement in the bowl rim have also been developed for high load applications. Such pistons were used in the Audi engine that won the Le Mans race. The cast-in fibers increase the load-bearing capacity at the bowl rim, and allow the pistons to withstand extremely high thermal loads without cracking.

Cooling, Coatings and Clearances

Another trick that’s done with many diesel pistons to use oil jets to help cool the pistons. When an oil jet is directed at the underside of the piston, oil is deflected into the gallery so it circulates behind the rings to carry away heat. This technique lowers the temperature of the top ring up to 100 degrees F or more to improve sealing, reduce blowby and emissions, and to extend the life of the piston and rings.

In performance and marine diesel engines, oil cooling is even more important. On a stock Duramax diesel that squirts 1.2 gallons of oil per minute at each piston, the flow can be doubled by using larger jets and a higher capacity external gear driven oil pump.

Cooling is improved even more by casting an oil cooling gallery into the top portion of the piston behind the upper ring land to dissipate heat. On some pistons, the cooling duct is created in the back of the top ring insert by welding on a steel plate.

so maybe we can use bigger cooling jets in the engines like in the marine duramax application

and get a piston that has fiber renforced piston bowel like the lemans audi diesel

Under Pressure

The pistons in a diesel engine must also withstand significantly higher compression pressures and operating temperatures than those in a gasoline engine. Because of this, the top piston ring runs hot. To reduce top ring pound out, most stock diesel pistons have a steel or iron insert for the top ring groove. This greatly improves the durability of the piston, and also allows the use of a keystone-shaped top ring to minimize ring sticking.

Because the pistons need a top ring groove insert for durability, the pistons must be cast rather than forged. Most use an alloy that contains 11 to 13 percent silicon so the pistons will have some ductility. To date, hypereutectic alloys with higher silicon levels have not been used for diesel pistons.

In heavy-duty high output engines, two-piece “articulated” pistons with steel crowns and aluminum skirts are often used for improved durability. The wrist pin holds the two pieces together, and allows the piston to handle higher loads than would be possible with a one-piece cast piston. Some engines also use a one-piece all-steel piston such as Mahle’s “Monotherm” piston or Federal Mogul’s “Monosteel” piston. The steel pistons are extremely durable and can handle the highest loads, but also tend to be heavy and expensive, costing up to three times as much as conventional cast aluminum pistons.

In recent years, diesel pistons with ceramic fiber reinforcement in the bowl rim have also been developed for high load applications. Such pistons were used in the Audi engine that won the Le Mans race. The cast-in fibers increase the load-bearing capacity at the bowl rim, and allow the pistons to withstand extremely high thermal loads without cracking.

Cooling, Coatings and Clearances

Another trick that’s done with many diesel pistons to use oil jets to help cool the pistons. When an oil jet is directed at the underside of the piston, oil is deflected into the gallery so it circulates behind the rings to carry away heat. This technique lowers the temperature of the top ring up to 100 degrees F or more to improve sealing, reduce blowby and emissions, and to extend the life of the piston and rings.

In performance and marine diesel engines, oil cooling is even more important. On a stock Duramax diesel that squirts 1.2 gallons of oil per minute at each piston, the flow can be doubled by using larger jets and a higher capacity external gear driven oil pump.

Cooling is improved even more by casting an oil cooling gallery into the top portion of the piston behind the upper ring land to dissipate heat. On some pistons, the cooling duct is created in the back of the top ring insert by welding on a steel plate.

so maybe we can use bigger cooling jets in the engines like in the marine duramax application

and get a piston that has fiber renforced piston bowel like the lemans audi diesel

Last edited:

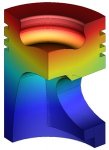

notice in this thermal image where most of the heat is . its in the crown and rim of the piston bowel

Diesel Engine Piston

In this model, a diesel engine piston is studied at steady-state conditions, that is, at a continuous engine speed and load. The combustion process at steady-state produces cyclic pressure loads and a high constant temperatures. These load conditions could yield a piston failure due to fatigue cracking, so-called high cycle fatigue cracks.

Diesel Engine Piston

In this model, a diesel engine piston is studied at steady-state conditions, that is, at a continuous engine speed and load. The combustion process at steady-state produces cyclic pressure loads and a high constant temperatures. These load conditions could yield a piston failure due to fatigue cracking, so-called high cycle fatigue cracks.

Attachments

ok so from what rip has posted after a hard run and back to a idle oil press is around 14 so that means the piston squirters arent even squirting at idle, see theres always a reason why a pistion cracks,like for instance if you had excessive piston to cyl wall distance you would have piston slap and would be cracking the piston skirts, so now i have seen in gas motors ring lands break from too much cylinder pressure from excessive boost and timing.

there has got to be a way to narrow this down to something other than shitty material in the piston, there is always a reason why a piston cracks and the way it cracks means a certain thing , so the more data we can bring to the table to look at the faster this problem can be solved .

does anyone have any data logging that they were doing when the piston let go in there truck?

you havent read the thread on DP.

Last edited:

I would geuss 250+ yet ive never seen a HOT OIL light that comes on at 300f IIRC

Im going to install a temp gauge for the oil on my truck this winter and start taking more note of it

Simon our trucks' ECM's do not monitor oil temp IIRC. I know there is a parameter in EFILive, but it doesnt do anything Im 99% sure.

ben

http://www.dieselplace.com/forum/showpost.php?p=1734224&postcount=165got a link?

http://www.dieselplace.com/forum/showpost.php?p=1734432&postcount=172

http://www.dieselplace.com/forum/showpost.php?p=1734535&postcount=175

http://www.dieselplace.com/forum/showpost.php?p=1734681&postcount=184

http://www.dieselplace.com/forum/showpost.php?p=1735647&postcount=201

http://www.dieselplace.com/forum/showpost.php?p=1735696&postcount=203

http://www.dieselplace.com/forum/showpost.php?p=1736042&postcount=208

Last edited:

Josh none of your links work for me

That's what I get for copy and pasting directly from a post. Try it now and let me know if it works.same

i think u would get more interesting results from 8 jets hooked up than just one things change when there is more oil coming out of other jets. just like a bunch of leaks in a water hose , u get a differnt reading of oil pressure from the bottom of the block than from the top , cause of all the oil leaking around all the bearings , also the oil pressure is lost as the engine heats up cause of the oil viscosity threw the pump