If there are any mechanical engineers in here, I need some help.

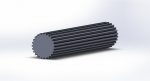

I have a splined shaft, that is 1.083" major OD, and has 25 teeth.

I'm thinking it must be metric, with a 26mm pitch dia?

Anyone familiar with involute splines?

Trying to locate an external spline for it.

I have a splined shaft, that is 1.083" major OD, and has 25 teeth.

I'm thinking it must be metric, with a 26mm pitch dia?

Anyone familiar with involute splines?

Trying to locate an external spline for it.