This is a continuation of Bdsankey's thread for is race truck batteries located here: Https://www.duramaxdiesels.com/forum/threads/race-truck-battery-batteries.88346/ but I didn't really want to hijack his thread so I am making a new one. Mods, if you want to copy the relevant parts over to this thread that would be great

I have no idea how this DIY version compares to commercially made ones as I don't have or use any. I only have my own experience in it's use and it appears to do the job with restoring the cranking capability and holding a charge for longer when sitting unused.

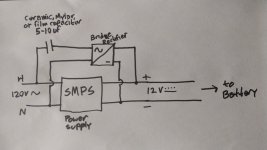

I start with finding a 12 volts DC power supply. 1 amp SMPS (switch mode power supply) seems to be quiet common supplied with all sorts of equipment, toys, routers, etc. so these are the ones I like to use.

you can usually squeeze them around the seem to get them open. sometimes knives or saws are required. this is of course it's glued or welded together and no screws.

this is what that latest one looks like that I will build here for you

often times there is extra room inside to add the necessary components.

I like to salvage my components from old used equipment. I tend to keep a few circuit boards laying around for this purpose.

that one was from an older projection TV. as you see, there are all sorts of goodies in here

here is what I pulled.

on the left is a full bridge rectifier and the right is a polyester capacitor. if the rectifier is pulling from the input power side of the board then it is already rated for the voltage. if pulled from anywhere else you'll have to check what the rating is before use. best practice is to use one rated for at least twice the peak to peak. 400 or more volt rating is what you are looking for if you have to buy one or are looking up the specs. for the capacitor, you need to use a low ESR or series equivalent resistance one. this basically is just a rating for how much resistance the capacitor has to current flow into and out of it. it's important because to high and the capacitor will over heat. that means those electrolytic, the ones that look like little cylinders with the specs heat shrinked on are off the table. the ones you want are typically film capacitors. they come in various types but I like the polyester type as in the above photo. My brain is too full of other useless information so I can never remember how to calculate the capacity of these so I always just Google for "capacitor value calculator" and punch in the numbers. on the one above, the "225" is the capacity. the "J" is the tolerance which is not important for use and the "250" is voltage rating. you'll often find ones with a voltage rating of 1.2k or 1.5k or similar. probably not worth using these as there capacity is much too low to be of any interest. the highest capacity one you can fit in your power supply and still get it back together is what you want to accomplish.

rule of thumb for this type of circuit is 25 uF used at 120 volts will pass 1 amp of charging current. Ideally you want at least as much current to counteract the self discharge rate of the battery. a standard lead acid battery of decent health may be in the 20 mA range. this would require at least a 1/2 uF capacitor but normally we are trying to use desulfators on less then healthy batteries so get as much as you can inside the case. the one I am using above is a 2.2uF which should push through about 88 mA. not great but not bad

I have no idea how this DIY version compares to commercially made ones as I don't have or use any. I only have my own experience in it's use and it appears to do the job with restoring the cranking capability and holding a charge for longer when sitting unused.

I start with finding a 12 volts DC power supply. 1 amp SMPS (switch mode power supply) seems to be quiet common supplied with all sorts of equipment, toys, routers, etc. so these are the ones I like to use.

you can usually squeeze them around the seem to get them open. sometimes knives or saws are required. this is of course it's glued or welded together and no screws.

this is what that latest one looks like that I will build here for you

often times there is extra room inside to add the necessary components.

I like to salvage my components from old used equipment. I tend to keep a few circuit boards laying around for this purpose.

that one was from an older projection TV. as you see, there are all sorts of goodies in here

here is what I pulled.

on the left is a full bridge rectifier and the right is a polyester capacitor. if the rectifier is pulling from the input power side of the board then it is already rated for the voltage. if pulled from anywhere else you'll have to check what the rating is before use. best practice is to use one rated for at least twice the peak to peak. 400 or more volt rating is what you are looking for if you have to buy one or are looking up the specs. for the capacitor, you need to use a low ESR or series equivalent resistance one. this basically is just a rating for how much resistance the capacitor has to current flow into and out of it. it's important because to high and the capacitor will over heat. that means those electrolytic, the ones that look like little cylinders with the specs heat shrinked on are off the table. the ones you want are typically film capacitors. they come in various types but I like the polyester type as in the above photo. My brain is too full of other useless information so I can never remember how to calculate the capacity of these so I always just Google for "capacitor value calculator" and punch in the numbers. on the one above, the "225" is the capacity. the "J" is the tolerance which is not important for use and the "250" is voltage rating. you'll often find ones with a voltage rating of 1.2k or 1.5k or similar. probably not worth using these as there capacity is much too low to be of any interest. the highest capacity one you can fit in your power supply and still get it back together is what you want to accomplish.

rule of thumb for this type of circuit is 25 uF used at 120 volts will pass 1 amp of charging current. Ideally you want at least as much current to counteract the self discharge rate of the battery. a standard lead acid battery of decent health may be in the 20 mA range. this would require at least a 1/2 uF capacitor but normally we are trying to use desulfators on less then healthy batteries so get as much as you can inside the case. the one I am using above is a 2.2uF which should push through about 88 mA. not great but not bad

Last edited: