Custom Duramax Engine Stand

- Thread starter Lq4chevy

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

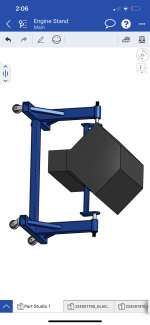

I took a lot of time trying to get it sitting at the correct height. Must have been dumb luck but the balance point is spot on. I can spin the thing with one finger. I should try to upload the video of it.

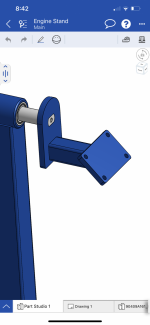

The slack adjuster I used for the worm gear has a little more black lash then I would prefer. So I came up with a locking mechanism to hold it in place once I have it at the orientation I want it to be

The slack adjuster I used for the worm gear has a little more black lash then I would prefer. So I came up with a locking mechanism to hold it in place once I have it at the orientation I want it to be

You know that wasn't an issue at all. I completely tore down that LLY to the bare block on the stand. At not once did the stand get in the way and I'm big dude 6'4 and overloading fiberglass ladders if you get my drift!very nice. only issue I see is that due to it's size and orientation and mount point it looks like it would make it difficult to sit beside it to work on the engine

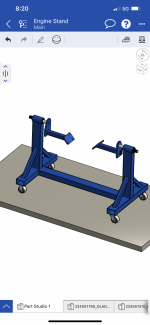

Now Ill tell you what was a HUGE design flaw lol its to wide for a cherry picker to fit a around and not tall enough for it to go under hah. I have worked around it by using a forklift or my picking point on my 2 post. I hate to say it but setting it on the stand never came into my mind during the design process, dummy

So what is the center line measurement between the engine motor mount adapter that created the perfect balance? This was an awesome build and I would really like to replicate it.I took a lot of time trying to get it sitting at the correct height. Must have been dumb luck but the balance point is spot on. I can spin the thing with one finger. I should try to upload the video of it.

The slack adjuster I used for the worm gear has a little more black lash then I would prefer. So I came up with a locking mechanism to hold it in place once I have it at the orientation I want it to be

Thank you for sharing!!!

Only thing that would make that better is some forklift pockets welded to the bottom side so i can scoop it right up and put it in the back of a truck.

Basically you want the rotational shaft inline with the deck. If I get a chance to work on mine, I will update my thread.

I have the version from Norco (same design) and it makes working on these things extremely easy and (to me) way less sketchy than a single sided mount like most do.very nice. only issue I see is that due to it's size and orientation and mount point it looks like it would make it difficult to sit beside it to work on the engine

I feel far more comfortable torqueing down things on the dual sided stand as opposed to a single side. Balancers, flexplates, 625 studs etc are all so much nicer on these type of stands. With how mine is shaped it has more clearance to the exhaust manifold area but that's due to the adapters from Norco to Duramax and how those were designed (third party).

Hey, you never posted pictures of those adapters...I have the version from Norco (same design) and it makes working on these things extremely easy and (to me) way less sketchy than a single sided mount like most do.

I feel far more comfortable torqueing down things on the dual sided stand as opposed to a single side. Balancers, flexplates, 625 studs etc are all so much nicer on these type of stands. With how mine is shaped it has more clearance to the exhaust manifold area but that's due to the adapters from Norco to Duramax and how those were designed (third party).