cracked piston

- Thread starter 1slomax

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

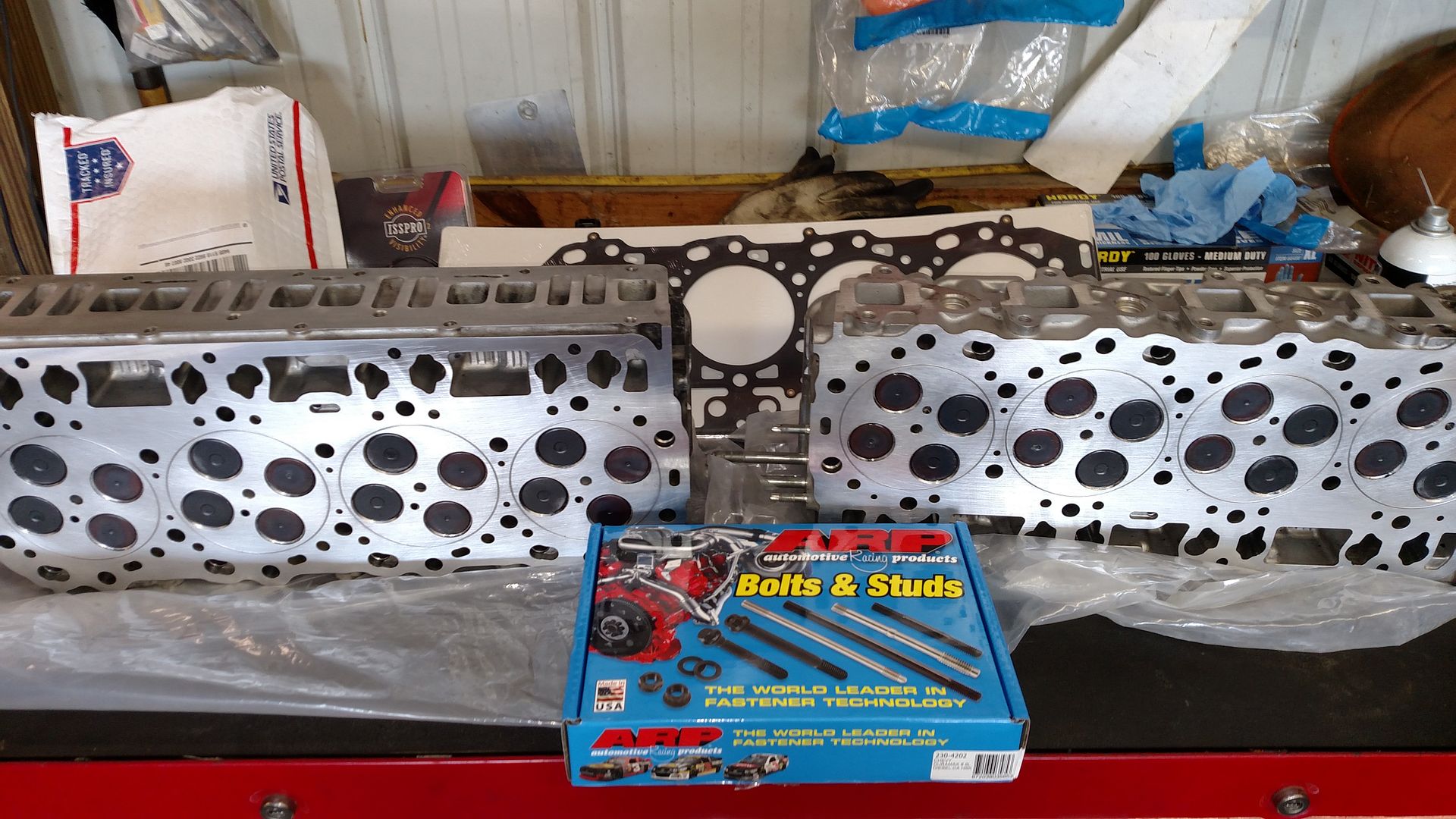

I've got my sleeves and head cut for an oring. Some people say it's not a good idea to ring a duramax because of how close the coolant ports are to the cylinder though

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

If your're already going to be machining for o-rings, why not drill out everything to fit Socal 14mm studs instead of the 625's?

That brings on a whole other list of issues that don't seem to be worth the trouble to me. Having to sleeve the bolt holes in the head because the broke out isn't my idea of a good time. Dealt with two motors with the 14mm studs and don't plan on it again anytime soon. The 625's have been more than effective for us so far. I'm a little more unorthodox than most I guess, so take it for what it is worth. We still run cast oval pistons in Brett's truck that goes 8.5xx@161mph in the quarter and yet guys are having issues with cracking Mahle race cast factory bowl pistons at 700-900hp range. Call me crazy but I'm going to continue doing what is working great for me.

That brings on a whole other list of issues that don't seem to be worth the trouble to me. Having to sleeve the bolt holes in the head because the broke out isn't my idea of a good time. Dealt with two motors with the 14mm studs and don't plan on it again anytime soon. The 625's have been more than effective for us so far. I'm a little more unorthodox than most I guess, so take it for what it is worth. We still run cast oval pistons in Brett's truck that goes 8.5xx@161mph in the quarter and yet guys are having issues with cracking Mahle race cast factory bowl pistons at 700-900hp range. Call me crazy but I'm going to continue doing what is working great for me.

Thanks for explaining. I've also cracked delipped cast mahle pistons in my old LMM, sucks.

Mark thanks for taking the time to me and explain everything it means a lot

No problem buddy, any time!:thumb:

Really good tech here guys! Speaking of building the bottom the best way possible, how do you guys feel about billet main caps compared to dowel pins in the stock caps? I'm having my billet main caps dowel pinned because I already had the billet main caps line bored when I started hearing about the dowel pins.

Thanks for explaining. I've also cracked delipped cast mahle pistons in my old LMM, sucks.

There's a decent difference between mahle motorsports pistons and mahle replacements, even if they're delipped..

Just food for thought, we ran stock de lipped LB7 pistons well over 100 passes at 1k hp in the Chevelle. We never cracked one until we started adding the N20 to it. I'm thinking they survived the conditions because of the 3560lb weight, but who knows. We never expected that motor to live as long as it did. Basically bone stock motor with Carrillos and std ARP 2000's @ 90+ psi boost.