Ok reviewed the pw and tq table settings, then implemented much of the advice above. As Dave mentioned, the PW values in lower mm3 rows/columns needed trimmed back a bit. I compared % subtracted from stock in Marks latest adjustment at higher mm3/MPa, and tapered up to it. Except in the low MPa / high mm3, range, and those I slashed 300% or so. That cleaned things up good bit on cranking, and she starts to light off nicely now at any fuel pressure, then stumbles. Argh..

Which brings my main observance so far, torque, torque, and torque tables.

These things live and breath on torque values. No matter what you change in FP, PW, ect, it always tries to maintain whatever torque value it's seeking by raising or lowering the Main Injection Flow Rate mm3 to get there. So if you undercut the PW value at say 50mm3 / 60MPa, it will just jack the mm3 up enough to satisfy the torque value it's targeting. Or cut it to reach what it "perceives" is the matching Nm value at FW..

That said, there is certainly some missing tables in our current LMM OS bag of tricks. Like boost PSI to torque limits, load based values, and crank to start transitions that Mark first mentioned last year. And there in lies the issue in any stand alone / engine dyno setting without BCM. I know how, and have full intentions of rectifying that problem for everyone soon as this builds done. But not today.

The E35x ECM experiences issues transferring between "Cranking" and "Running" modes whenever "it's" not in control of the starter relay. IE, if your truck misfires on cranking, the ECM kicks out the starter relay automatically, and then you turn key again, and tell the BCM to tell the ECM to start again. In this setup I can crank it till the starter falls off, but once it fires off and fails to start once, it won't refire until I let off the key and RPM falls to 0.. Even-though the data logs shows it still fueling... Go Figure.

So I've logged enough data now to understand why it's stumbling right after firing, but still can't trick it into just grabbing ahold and kicking enough fuel in soon as it lights off. Can do this by adding some throttle. But at 0%TPS, ECM's killing the mm3 value soon as it detects firing or a load value on engine. Exact same time it transfers between cranking torque table B1127 and Pedal Position Mode A B1161. Possible we can use some IAT and ECT multiplier combo trick to let it know it's a cold start.

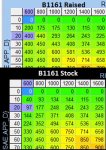

If ya pull up the tables above, you'll notice that while B1127 goes up to 1400Rpm, by default GM only places torque values up to 1000Rpm. While B1161 starts at 600Rpm, and row [TPS-D 0%] must always = 0.0 Nm across the board. Next row [TPS-D 10%] has stock valves of like 40Nm at 600Rpm. Which I've push up to 180Nm with little change.

So, soon as it fires off with a requested cranking TQ of say 700Nm@500Rpm, the ecm detects a load, switches to running table B1161 and seeks the torque value in the TPS-D% matching 600Rpm cell. IE 180Nm and Bang you've overshot new torque value, cut the mm3 fuel. Then it says oh shit, I lost my mojo and attempts to recover set idle Rpm by jacking mm3 back up. If it misses that one shot, then it says F-it, lets start over again at 0Rpm.

If I set a cranking TQ table with rounded off edges so it starts pulling requested Nm at say 350-500Rpm, she spins up nice and smooth even cold as ice, and acts like its gonna take off. Then when tables switch, it stumbles to adjust mm3, and then stops fueling. If i jack the cranking torque tables up, it pushes FP and mm3 way up, and she hits off hard, but typically overshoots set idle [820Rpm currently] and once again pulls fuel completely out half sec, and can't recover..

So that's where I'm at today. Sorry for the novel, but have a look at the log pics below from same key on set.

Feel free to toss up any suggestions. As mentioned Mark has experienced / fought this issue a good bit on the engine dyno. Fix has been push up the cranking torque up to get over the hump from waterbrake drag. Now they have zero drag on em at cranking / idle.

Which brings my main observance so far, torque, torque, and torque tables.

These things live and breath on torque values. No matter what you change in FP, PW, ect, it always tries to maintain whatever torque value it's seeking by raising or lowering the Main Injection Flow Rate mm3 to get there. So if you undercut the PW value at say 50mm3 / 60MPa, it will just jack the mm3 up enough to satisfy the torque value it's targeting. Or cut it to reach what it "perceives" is the matching Nm value at FW..

That said, there is certainly some missing tables in our current LMM OS bag of tricks. Like boost PSI to torque limits, load based values, and crank to start transitions that Mark first mentioned last year. And there in lies the issue in any stand alone / engine dyno setting without BCM. I know how, and have full intentions of rectifying that problem for everyone soon as this builds done. But not today.

The E35x ECM experiences issues transferring between "Cranking" and "Running" modes whenever "it's" not in control of the starter relay. IE, if your truck misfires on cranking, the ECM kicks out the starter relay automatically, and then you turn key again, and tell the BCM to tell the ECM to start again. In this setup I can crank it till the starter falls off, but once it fires off and fails to start once, it won't refire until I let off the key and RPM falls to 0.. Even-though the data logs shows it still fueling... Go Figure.

So I've logged enough data now to understand why it's stumbling right after firing, but still can't trick it into just grabbing ahold and kicking enough fuel in soon as it lights off. Can do this by adding some throttle. But at 0%TPS, ECM's killing the mm3 value soon as it detects firing or a load value on engine. Exact same time it transfers between cranking torque table B1127 and Pedal Position Mode A B1161. Possible we can use some IAT and ECT multiplier combo trick to let it know it's a cold start.

If ya pull up the tables above, you'll notice that while B1127 goes up to 1400Rpm, by default GM only places torque values up to 1000Rpm. While B1161 starts at 600Rpm, and row [TPS-D 0%] must always = 0.0 Nm across the board. Next row [TPS-D 10%] has stock valves of like 40Nm at 600Rpm. Which I've push up to 180Nm with little change.

So, soon as it fires off with a requested cranking TQ of say 700Nm@500Rpm, the ecm detects a load, switches to running table B1161 and seeks the torque value in the TPS-D% matching 600Rpm cell. IE 180Nm and Bang you've overshot new torque value, cut the mm3 fuel. Then it says oh shit, I lost my mojo and attempts to recover set idle Rpm by jacking mm3 back up. If it misses that one shot, then it says F-it, lets start over again at 0Rpm.

If I set a cranking TQ table with rounded off edges so it starts pulling requested Nm at say 350-500Rpm, she spins up nice and smooth even cold as ice, and acts like its gonna take off. Then when tables switch, it stumbles to adjust mm3, and then stops fueling. If i jack the cranking torque tables up, it pushes FP and mm3 way up, and she hits off hard, but typically overshoots set idle [820Rpm currently] and once again pulls fuel completely out half sec, and can't recover..

So that's where I'm at today. Sorry for the novel, but have a look at the log pics below from same key on set.

Feel free to toss up any suggestions. As mentioned Mark has experienced / fought this issue a good bit on the engine dyno. Fix has been push up the cranking torque up to get over the hump from waterbrake drag. Now they have zero drag on em at cranking / idle.

Attachments

Last edited: