Rob, There are no kinks in the return line, it is flowing full blast back into the filler neck.

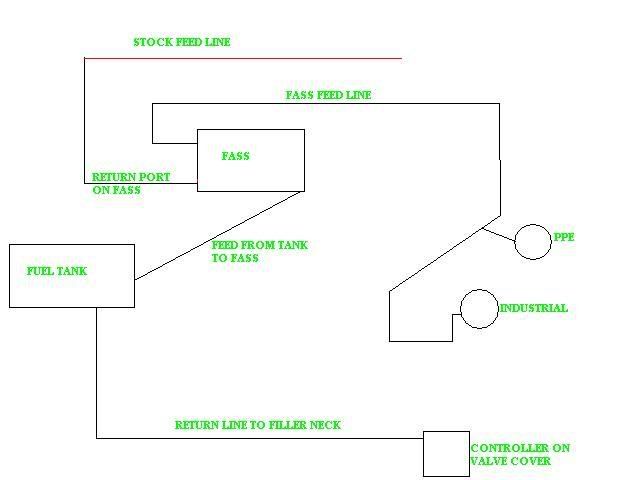

Mitch, It is a FASS for the duramax. The feed line comes from the FASS directly to the PPE CP3 and T's off, then goes over to the FICM. The return line leaves there and goes back to the filler neck. The return line off the FASS actually routes back into the stock metal lines back by the tank.

I have my stock CP3 in storage, so I could swap regulators to see if that changes anything. I'm out of time to play with it for at least a week now. I'll be out of town until Dec. 13th. Mark Broviak routed everything, and he should be back from vacation on Wednesday. Larry at Danville said Jon had this problem before too. Hopefully Mark will have the fix since he has had this problem before.

McRat, I'll try that when I'm back in town. Now I have to do maintenance on the old faithful LLY since it gets neglected but still manages to always be reliable

Mitch, It is a FASS for the duramax. The feed line comes from the FASS directly to the PPE CP3 and T's off, then goes over to the FICM. The return line leaves there and goes back to the filler neck. The return line off the FASS actually routes back into the stock metal lines back by the tank.

I have my stock CP3 in storage, so I could swap regulators to see if that changes anything. I'm out of time to play with it for at least a week now. I'll be out of town until Dec. 13th. Mark Broviak routed everything, and he should be back from vacation on Wednesday. Larry at Danville said Jon had this problem before too. Hopefully Mark will have the fix since he has had this problem before.

McRat, I'll try that when I'm back in town. Now I have to do maintenance on the old faithful LLY since it gets neglected but still manages to always be reliable