Attn: People running ARP head studs

- Thread starter Kat

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It has just come to our attention that ARP has changed the torque spec's form 96 ft lbs to 125 ft lbs.

thanks for the info Kat:hug:

Also do you know if you run them for a bit then re-torque

and should a peson torque in steps? like 60-90-126?

thanks for the info Kat:hug:

Also do you know if you run them for a bit then re-torque

and should a peson torque in steps? like 60-90-126?

I don't have a clue but I will find and let you know tomorrow

It seems though it would be hard to re-torque them though

well ya it would be a total pain in the butt, i just remember reading a couple threads about this issueI don't have a clue but I will find and let you tomorrow

It seems though it would be hard to re-torque them though

Torque them the first time!!

whenever i tourque alot of bolts, I will useally go in steps

i would tourque them to 126 before i was done with them just wondered what others do?

I always have them all Tight and then torque them down to spec. I only have experience with CNC machines and heavy equipment, no dmax's.

To be honest, Sometimes i just tighten the shit out of things

Always use a cross pattern starting from the middle and work your way out. Also do it in steps to ensure you have an even displacement of pressure across the surface of whatever you are tightening.

This is a pretty much standard rule to go by when tightening/torquing pretty much everything! Or at least in my world it's my standard and I have never had a problem. Most manufacturer's would probably agree though.

Simon-You need to by about 3 torque wrenches of different sizes-I've seen you work!!

This is a pretty much standard rule to go by when tightening/torquing pretty much everything! Or at least in my world it's my standard and I have never had a problem. Most manufacturer's would probably agree though.

Simon-You need to by about 3 torque wrenches of different sizes-I've seen you work!!

To be honest, Sometimes i just tighten the shit out of things

Thats what I do most of the time.

ARP says to bring the bolts up to spec, then loosen them, then tighten again. 4 Times!

After you do that once, you do not have to do it again.

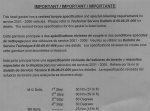

I'm going another step - I'm polishing the threads with a wirewheel to get even more repeatable torquing. You can feel that the nuts spin freer than unpolished. See pics:

After you do that once, you do not have to do it again.

I'm going another step - I'm polishing the threads with a wirewheel to get even more repeatable torquing. You can feel that the nuts spin freer than unpolished. See pics:

Attachments

No, the studs have an allen head, but you are NOT supposed to tighten the studs themselves.

You lube up everything with moly assembly lube (threads, washers, nuts) then screw the studs in finger tight. Well, the threads will hydrolock a little with the lube, so screw it down til it stops with an allen wrench, loosen, then go finger tight. Then put on the washers, then nuts. I'm going 40lb then 80lb, then 125lb per GM ordering, then loosening, and repeating 3 times.

Interesting that the head gaskets come with a warning label that says to ignore the GM book specs and tighten to 60 deg + 60 deg instead of 90 deg + 75 deg. Or in other words, GM wants you to NOT tighten the OEM headbolts as much as before. Interesting.

You lube up everything with moly assembly lube (threads, washers, nuts) then screw the studs in finger tight. Well, the threads will hydrolock a little with the lube, so screw it down til it stops with an allen wrench, loosen, then go finger tight. Then put on the washers, then nuts. I'm going 40lb then 80lb, then 125lb per GM ordering, then loosening, and repeating 3 times.

Interesting that the head gaskets come with a warning label that says to ignore the GM book specs and tighten to 60 deg + 60 deg instead of 90 deg + 75 deg. Or in other words, GM wants you to NOT tighten the OEM headbolts as much as before. Interesting.

ARP has now released an upgrade to the previous studs 625's are now on the shelf.

Stretched my old ARP's.

Stretched my old ARP's.