here is an interesting one.

So ive had a rattle upon hitting the throttle from a stop or when hitting the throttle from a coast off boost like after a long downhill. its been there for quite some time but never been my top priority to look into, specially cause i only really notice it in higher elevation where the stock turbo spools slower. After my trip to silverton and back, im looking into this as it gets real annoying pulling passed or starting from lights sounding like an old 7.3.

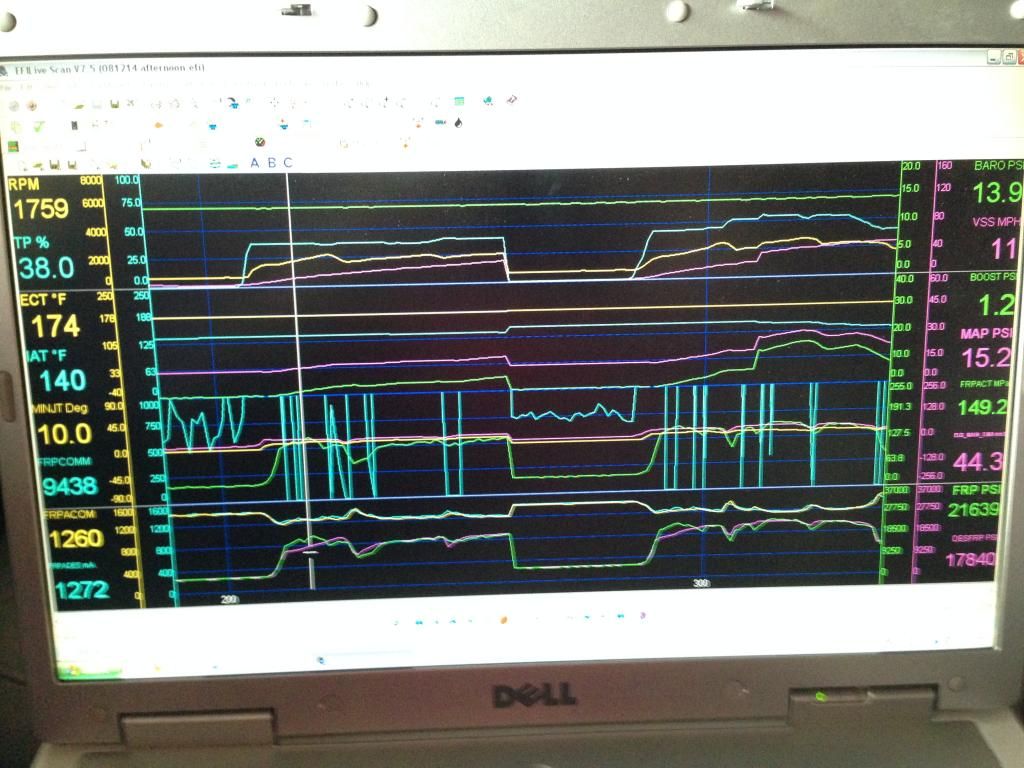

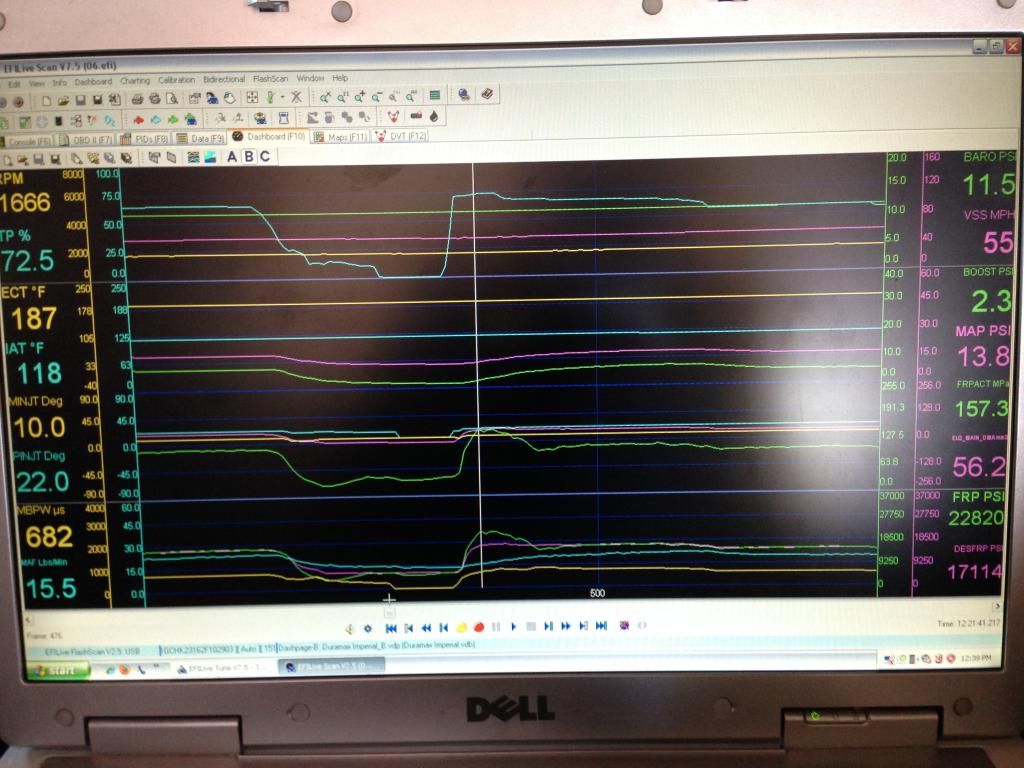

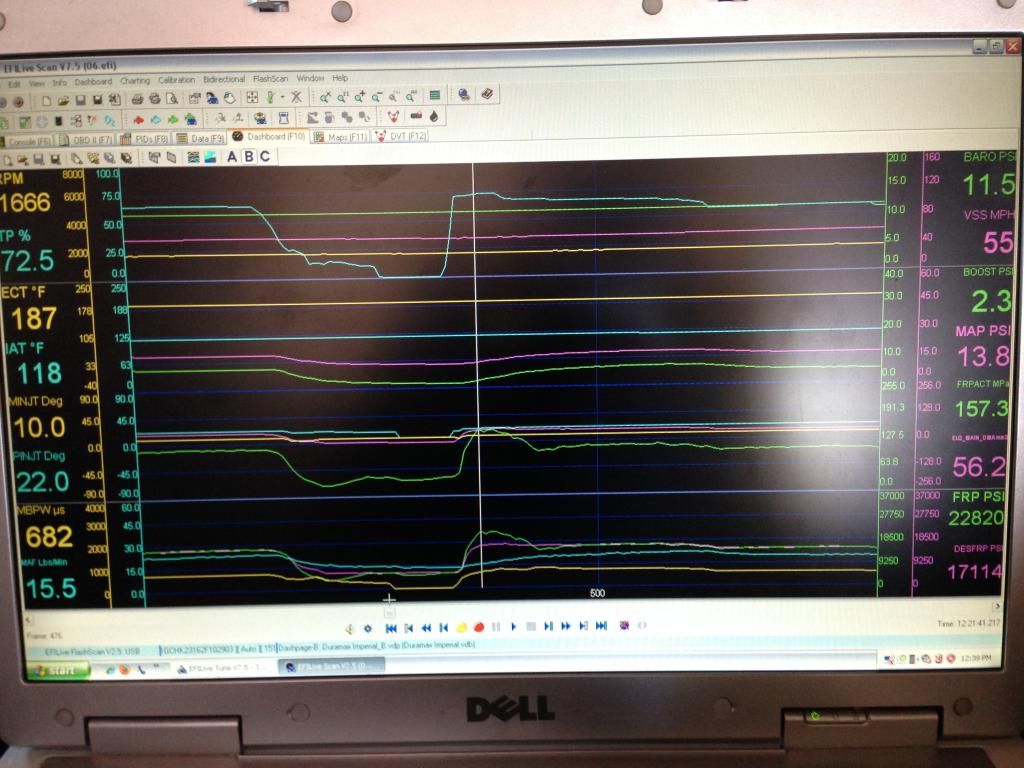

here is a screen shot of my rail issue

it will do this every time. if im easy with depressing the throttle, it can get it to follow nicely and it wont rattle. Nothing as far as tuning in for my rail is different than stock. i have stock lb7 regulators in each pump and the valley one is new but it rattled just like this prior to that change. idle rail will hold perfect and cruising it will hold perfect, its only the initial throttle tip in from normal acceleration.

thoughts? i thought maybe lift pump pressure too high but figured that would cause it to run high rail all the time, specially at idle which isnt the case. maybe my second pump controller is going bad or not right?

So ive had a rattle upon hitting the throttle from a stop or when hitting the throttle from a coast off boost like after a long downhill. its been there for quite some time but never been my top priority to look into, specially cause i only really notice it in higher elevation where the stock turbo spools slower. After my trip to silverton and back, im looking into this as it gets real annoying pulling passed or starting from lights sounding like an old 7.3.

here is a screen shot of my rail issue

it will do this every time. if im easy with depressing the throttle, it can get it to follow nicely and it wont rattle. Nothing as far as tuning in for my rail is different than stock. i have stock lb7 regulators in each pump and the valley one is new but it rattled just like this prior to that change. idle rail will hold perfect and cruising it will hold perfect, its only the initial throttle tip in from normal acceleration.

thoughts? i thought maybe lift pump pressure too high but figured that would cause it to run high rail all the time, specially at idle which isnt the case. maybe my second pump controller is going bad or not right?