83mm turbine wheel potential?

- Thread starter mike diesel

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

what about a stock bottom end? would it be best for 83 or 87?I don't recommend the 83mm for Dmax's at all, I only use the 87mm turbine or 96mm turbine. Cummins like the 83mm it seems though, lol.

On stock bottom end the 87mm still out performs the 83mm everywhere. I did it on my stock lmm motor with stock sticks and it was a bigger difference than I previous thought it would be. I'll find the dyno sheet to show you guys.

Just the turbine change itself

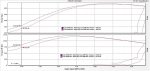

Here is the dyno sheet from my truck and this was just the swap from 83mm .90ar to the 87mm .90ar. It's pretty obvious that my stock injectors are my limiting factor up top but down low is where the info is really good. Against my thoughts, the 87mm drove better and was faster to respond down low than the 83mm. I put the curser at 2K rpm to show the difference in HP and Tq there and it's quite a bit. Add fuel and they get even better!

Here is the dyno sheet from my truck and this was just the swap from 83mm .90ar to the 87mm .90ar. It's pretty obvious that my stock injectors are my limiting factor up top but down low is where the info is really good. Against my thoughts, the 87mm drove better and was faster to respond down low than the 83mm. I put the curser at 2K rpm to show the difference in HP and Tq there and it's quite a bit. Add fuel and they get even better!

Attachments

Good info Mark. Most guys just consider peak numbers when they buy parts. It us the power under the curve that makes the most differences not the peak numbers

Exactly, I care about the curve far more than the peak number!:thumb:

Marks 100% correct on this. The 87 is a all around better wheel then the 83, all though baby 5.9 cummins trucks tend to like the 83 wheel for drivability. Generally the 83 taps out around 830rwhp from what I've seen. Duramax trucks love the larger turbine for sure. The 92 is definitely a wheel I wouldn't care to use for anything.

On stock bottom end the 87mm still out performs the 83mm everywhere. I did it on my stock lmm motor with stock sticks and it was a bigger difference than I previous thought it would be. I'll find the dyno sheet to show you guys.

Thank you, I have a new FPE charger to install, I need to check to see what the size the turbine wheel is

Fleece uses the 87

Ok thank you! It's been a while since I ordered it and got my hsp kit, I'm finally doing gaskets and studs so I'm installing here in the next week. I just didn't know what they used, glad to hear it's the better option!

Fleece uses the 87

Depends on the application. The information portrayed in this thread does not portray all the data, which is not so unanimously for an "87mm" Turbine in every application.

There are a few things to bring to light in this discussion.

1) There is 2 common "87mm S400" turbines, and 1 less common option. So with out specific technical data of a turbine, it may not always be an apples to apples comparison.

2) As a general rule of thumb, Compressor Inducer Determines Spool-up & HP potential. Turbine wheels & TH A/R determine where in relation to RPM the HP/TQ lands. (An easy comparison, is the common FMW profile of the 67.7x95 wheel vs the common 63x95 wheel. Exducer Dimensions and radius are nearly identical. The 67 will spool "slower", and require more energy to drive than the 63 if both were fitted with the same turbine.)

At FPE we use the 83mm turbine on small inducer setups, like the cast 63x95 & cast 67x100 wheels. Why? Because when we tested on the street and dyno with several 87mm turbine options there was little to no gain over all, over the 83mm turbine in the power range the Compressor could support, and their respective reliable power ratings. Regardless of application. Yet with our larger, and arguably more aggressive Billet Compressors, there is a significant difference in power and response with the 87 over the 83.

Caleb