Fall 2018

Here are some images of the carnage from the turbo failure that happened on the streets of Mexico.

Here are some images of the carnage from the turbo failure that happened on the streets of Mexico.

Do not forget that Rick Lance can build you any height t6 you need !

I did not read back thru to see if you mentioned but you will need a 5.5" tall t6 pedestal to fit with your body style truck, plus some light massages to the cowl

Sent from my SM-G960U using Tapatalk

Those are nice performance upgrades. Any more updates?

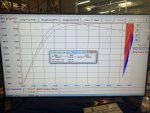

I used an o ringed drain flange on our pull tk. Comes in handy when dyno testing bunch of turbos.The Motion Raceworks 10AN oil drain flanges showed up today.

I used an o ringed drain flange on our pull tk. Comes in handy when dyno testing bunch of turbos.

Sent from my SM-G960U using Tapatalk

Be interested to see how she responds. :thumb:

Things are getting fun now i see:happy2: