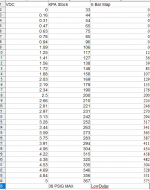

I'm having some confusion. My truck is the '02. The MAP reads pressure, and then the BARO adjusts it for ATM, right? So wouldn't the MAP sensor need to output in PSIA and then the Baro sensor adjusts it to PSIG for a Boost reading when I log/scan? I ask because I am looking to swap and rescale my MAP for higher boost, and Lowdoller's sensors all report PSIG. I expected their MAP sensors to output in PSIA and Boost sensors to report in PSIG.

Or do I just adjust for this in my scaling, eg. if at a certain voltage the LD MAP reads 10psig, I scale that as a 24.7psi instead of 10psi in EFI Live? I am probably making this harder than it needs to be, LMAO. Thanks in advance

Or do I just adjust for this in my scaling, eg. if at a certain voltage the LD MAP reads 10psig, I scale that as a 24.7psi instead of 10psi in EFI Live? I am probably making this harder than it needs to be, LMAO. Thanks in advance