LB7: LBZ intake manifolds on LB7

- Thread starter Vrabel

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

You have to run the lbz manifolds then mod a lbz van bridge or cough up the change for one already done from Ppe. Then you use your lb7 intercooler pipe with it.

Lb7 bridge won't bolt to lbz manifolds. Personally I dont think its worth the cost and hassle for no real proven gains.

a regular bridge wont work?

if you mean a stock bridge from a lbz yea but your LB7 is easier to work around then my lbz bridge I have now.The reason the LBZ guys run the van bridge is to have the inlet off set to the side like the lb7 to clear a biggier intake. The van bridge is alot biggier thru the center and will flow more and the manifolds flow alittle better then the lb7 manifolds.

oh, I have an LBZ bridge. It looks just like the one on Henry's motor in modded rail fitting thread. I read it flow more air than LB7. I was Talking to rick D'lance a while back, He explained how the LB7 bridge has a design flaw because its angled. By forcing more air towards drivers side.

look at the lbz bridge you have then look at this one.The stocker I can not get my hand through but on the van bridge its alot more girth in the center and I can fit my big hand into it. I know that doesnt mean much but it does show the extra volume it has also you loose the front inlet that screws you from having a nice full size 5" intake on a big turbo.

No, that's not what I have. I have two pieces. The lower half, and a slip fit pipe that's a hard 90

Thats a stock LBZ y-bridge , what Henry is talking about is taking the van bridge he pictured and cutting the stock piece off the top and welding your own pipe to it that mates up to the stock IC tube . I have built customs ones using both the stock piece and the van , the van is much easier because you dont have to weld the front hole off , but is 100 bucks so ................... other than that the runners should bolt to LB7 heads and the rest should work .No, that's not what I have. I have two pieces. The lower half, and a slip fit pipe that's a hard 90

once I get mine back from my welder, i'll post a pic, it's very similar to Ricks pro-flow lbz bridge. I used a stock lbz bridge and am having a divider welded inside to direct even flow to both banks. with a 3" 90* inlet pipe welded to a bushing i had made to take up the extra room.

Thats a stock LBZ y-bridge , what Henry is talking about is taking the van bridge he pictured and cutting the stock piece off the top and welding your own pipe to it that mates up to the stock IC tube . I have built customs ones using both the stock piece and the van , the van is much easier because you dont have to weld the front hole off , but is 100 bucks so ................... other than that the runners should bolt to LB7 heads and the rest should work .

Yes ans yes the manifolds bolt right up to the lb7 trucks

once I get mine back from my welder, i'll post a pic, it's very similar to Ricks pro-flow lbz bridge. I used a stock lbz bridge and am having a divider welded inside to direct even flow to both banks. with a 3" 90* inlet pipe welded to a bushing i had made to take up the extra room.

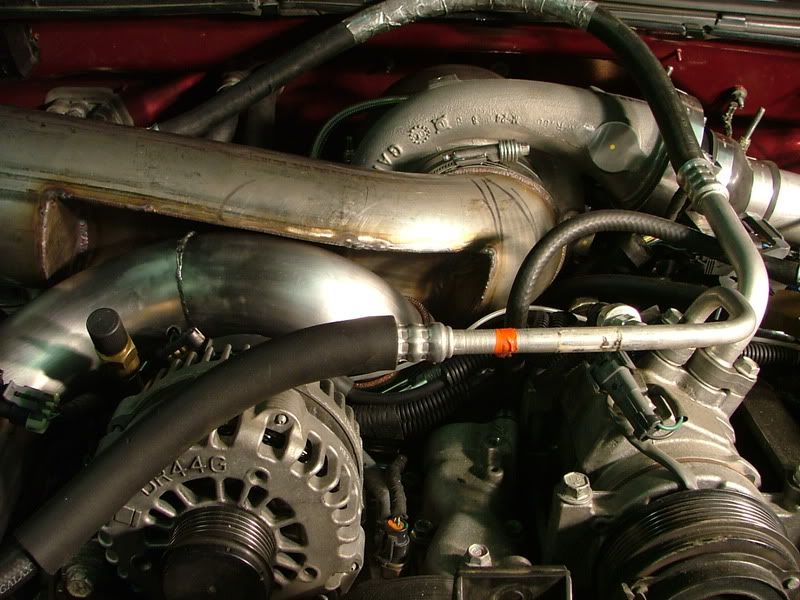

Be neat to see how it turns out I just dont see the bend giving enough room. I wish I used a Van bridge on my truck when we did this mess.

Maybe mount the turbo alittle higher would of made the intake cleaner. But Still not enough room without a tight bend.

Guess I cant cry to bad lol still ran 11.53 with this junk setup on it.

Knockin' on 10s and when the hood is closed who knows if you didn't make it like you wanted the first time. Nice time which pistons and rods are you using? Just see the stock piston let go.

I'm running Crower rods and Socal cut and coated LB7 pistons, with a keyed crank and cam stock main bolts stock cam stock heads. Balanced and arp head studs. I wish I redid the intake before removing the Gt4202R and got a biggier tune and took some weight out but I did not get a chance to had to move from Md to Mo. The tunning was not that wild on the run at that and sucking thru that 5" intake with that was the air was hitting had to hurt it. Truck weight was 6980 and it was on M&H dots spinning all nothing else other then lowing shackles. I hope to have a new toy towards this winter to play with for next year and this will be the GF's DD and tow truck.

Be neat to see how it turns out I just dont see the bend giving enough room. I wish I used a Van bridge on my truck when we did this mess.

Maybe mount the turbo alittle higher would of made the intake cleaner. But Still not enough room without a tight bend.

Guess I cant cry to bad lol still ran 11.53 with this junk setup on it.

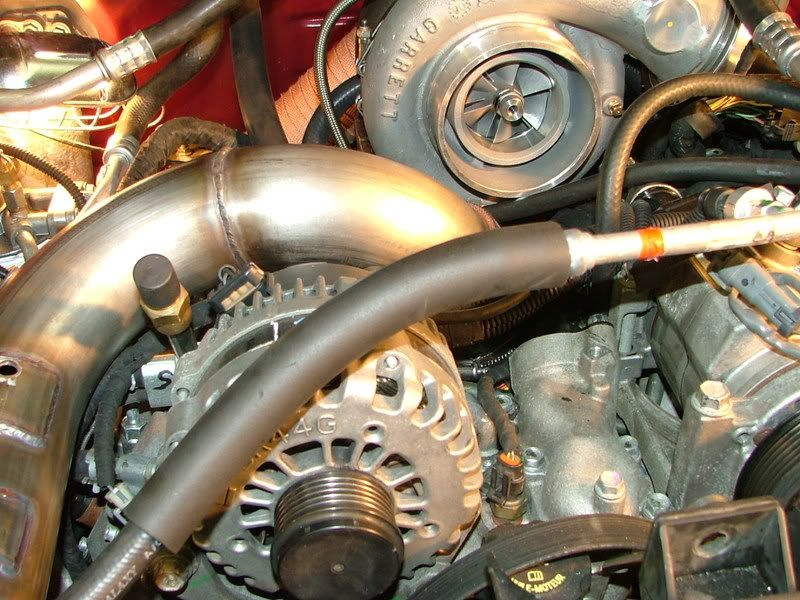

I am running an RDL pedistal which is a bit higher but not much. I am using a van thermo housing and i plan to bring the cold pipe over the alternator or in front of it. I see what you meant about the room, it would work with a van bridge, but I am hoping since the rubber elbow im using on the compressor housing is just that, rubber, that i can make it work. if not, then I buy a van bridge, lol, and have crappy flow.

thanks for reposting the pics Henry

On the van bridge just hack the hole top off and come out with 3" not just add to the top like the one PPE has if you want it biggier then port the inside some and add a divider to help it flow. Doesnt hurt to have pics in more then one thread lol saves from finging the links to were I had posted them before anyways and having to go thread to thread to talk about the other.

lol, true. maybe i have a mental block against a divider in a van bridge, but i cant really visualize that working as well. i wish it was a competition only motor and i didnt need AC or anything, i'd build a plenum or buy the ZZ setup in a heartbeat.