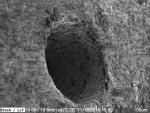

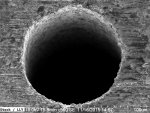

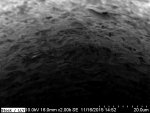

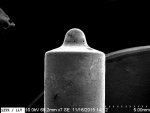

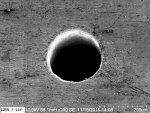

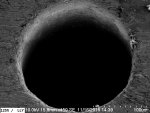

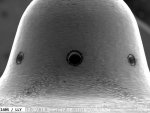

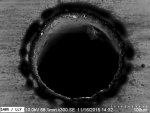

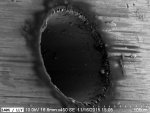

For anyone interested, I have some very up close views of some of my injector nozzles. I have images of stock, "125% over", and "140% over" nozzles.

These images were produced with a scanning electron microscope at 7-2,000x magnification. The accelerating voltage was 10.0kV and the emission current was 0.102-0.104mA.

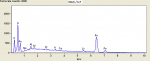

The material analysis was done using energy dispersive xray spectroscopy.

These images were produced with a scanning electron microscope at 7-2,000x magnification. The accelerating voltage was 10.0kV and the emission current was 0.102-0.104mA.

The material analysis was done using energy dispersive xray spectroscopy.