Hey guys, I've been lurking here for a long time but haven't posted much. I bought an 06 lbz in February, and have since put around 20000 miles on it and a couple upgrades.

I started getting a lot of pressure in my cooling system about a month ago, and got the dreaded hard upper hose in the mornings while the truck was cold. I deleted my egr cooler from the cooling system, had blocker plate but boost was still entering cooler, and still had a lot of pressure in the system. After finally accepting my fate I began tear down 2 weeks ago. Progress has been slow due to holidays and late nights at work but I figured I would post my progress up here and start a thread. Progress may be somewhat but I'm hoping it will be up and running the week after new years.

Parts list:

Grade C gaskets and upper gasket kit from Creatures of the night performance

ARP headstuds

LML manifold

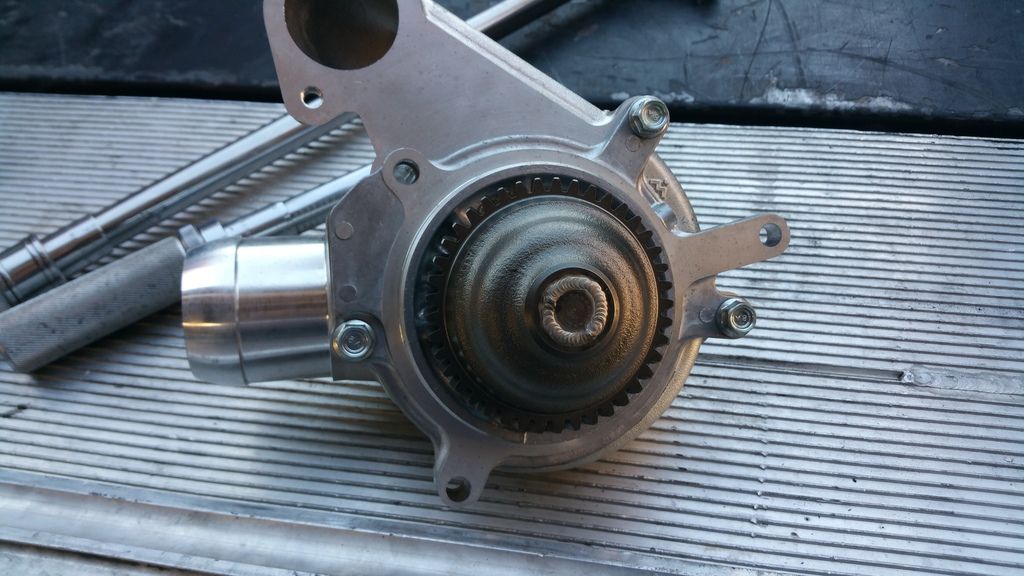

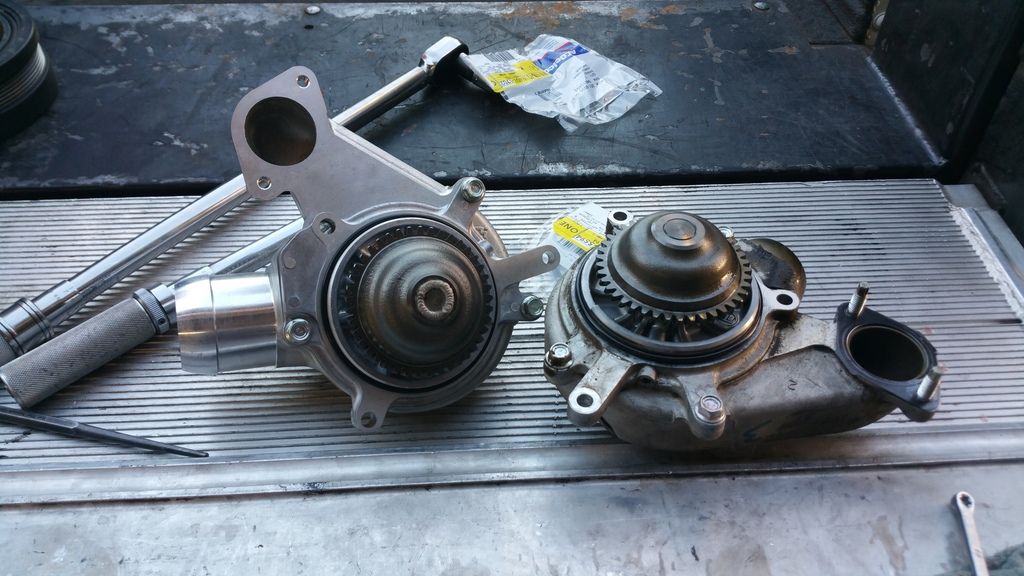

New GM water pump - tig welding myself

New GM thermostats

New lbz FPR

New exhaust bolts and injector hold down bolts

SDP high flow y-bridge and cold/hot pipes

Here's a couple pics from when I got the truck

And a more current shot.

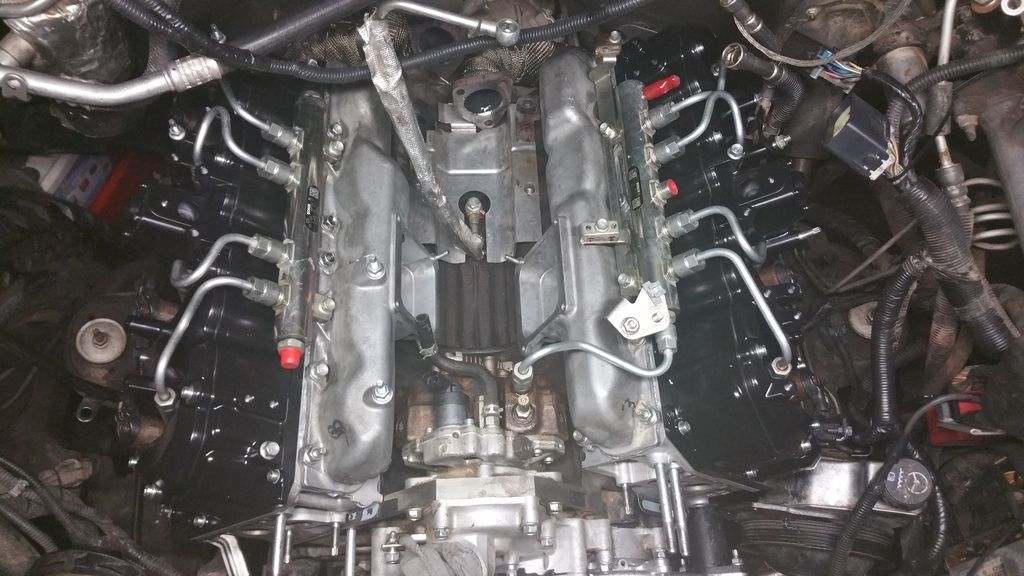

A shot of the engine bay before teardown

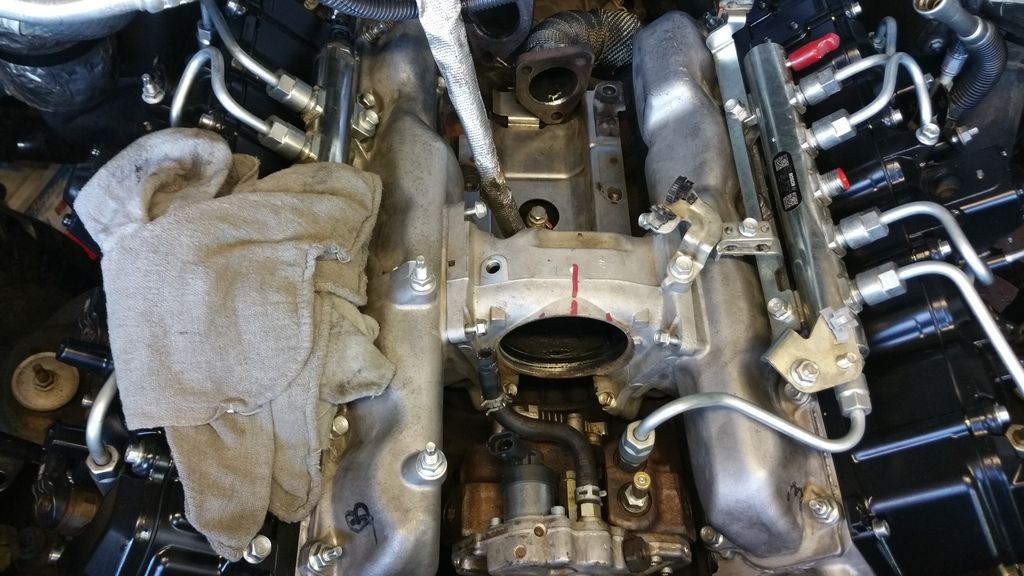

And the teardown begins

I pulled the turbo to finish porting and polishing the housings and clean the white paint off

Egr gunk - I installed a blocker plate when I bought the truck at 98,500, truck is now at 118800, crazy how much is still in here

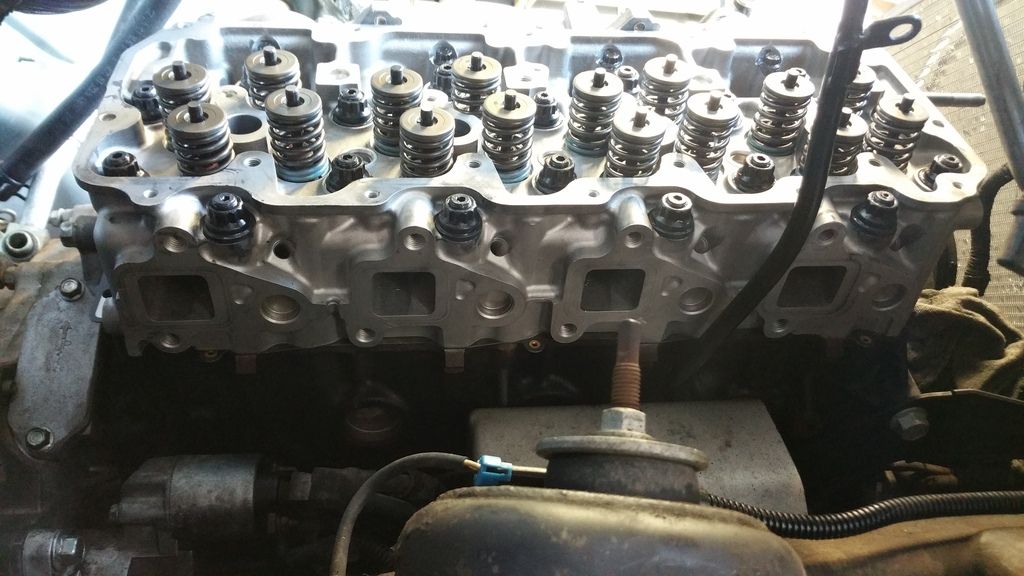

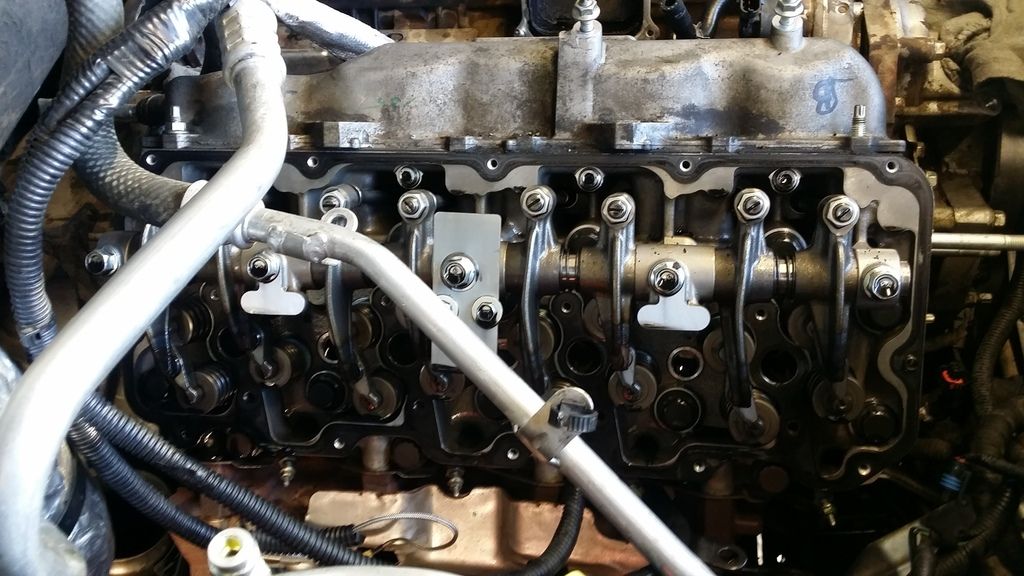

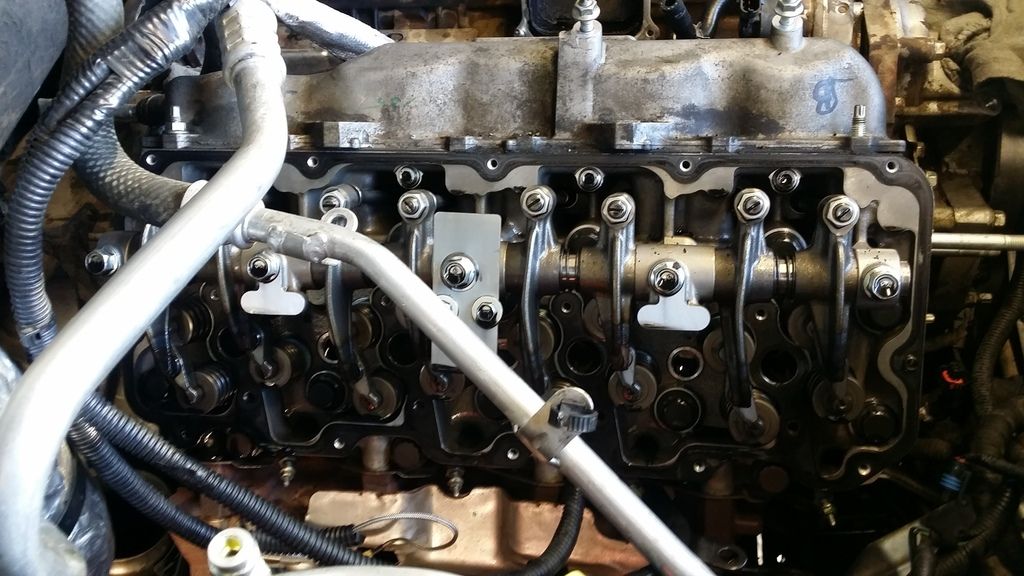

Finally got the first head off

I've been doing all this out of a garage that is way too small for my truck as well, and working out of my service truck. The limited space deffinatly made this job a little more difficult, and has made working on anything else in the garage impossible.

Found gasket was leaking on #6 close to an exhaust valve right where the drivers side manifold kinks down. My truck had the old crimped style headgaskets as well.

Cleaned up the heads and valves and found I have 1 bad valve guide. Its on cylinder 5 intake closest to the intake runner.(#23 in picture). Bringing the heads to get surfaced and get the guide replaced tomorrow then I will be doing the valve job myself.

I will update with pictures as I go but it will most likely be the end of the week before any real progress happens. If anyone has anything that I should add while i'm here please feel free to chime in.

I started getting a lot of pressure in my cooling system about a month ago, and got the dreaded hard upper hose in the mornings while the truck was cold. I deleted my egr cooler from the cooling system, had blocker plate but boost was still entering cooler, and still had a lot of pressure in the system. After finally accepting my fate I began tear down 2 weeks ago. Progress has been slow due to holidays and late nights at work but I figured I would post my progress up here and start a thread. Progress may be somewhat but I'm hoping it will be up and running the week after new years.

Parts list:

Grade C gaskets and upper gasket kit from Creatures of the night performance

ARP headstuds

LML manifold

New GM water pump - tig welding myself

New GM thermostats

New lbz FPR

New exhaust bolts and injector hold down bolts

SDP high flow y-bridge and cold/hot pipes

Here's a couple pics from when I got the truck

And a more current shot.

A shot of the engine bay before teardown

And the teardown begins

I pulled the turbo to finish porting and polishing the housings and clean the white paint off

Egr gunk - I installed a blocker plate when I bought the truck at 98,500, truck is now at 118800, crazy how much is still in here

Finally got the first head off

I've been doing all this out of a garage that is way too small for my truck as well, and working out of my service truck. The limited space deffinatly made this job a little more difficult, and has made working on anything else in the garage impossible.

Found gasket was leaking on #6 close to an exhaust valve right where the drivers side manifold kinks down. My truck had the old crimped style headgaskets as well.

Cleaned up the heads and valves and found I have 1 bad valve guide. Its on cylinder 5 intake closest to the intake runner.(#23 in picture). Bringing the heads to get surfaced and get the guide replaced tomorrow then I will be doing the valve job myself.

I will update with pictures as I go but it will most likely be the end of the week before any real progress happens. If anyone has anything that I should add while i'm here please feel free to chime in.

Last edited: