I figured I would try out something here and see what you all think. I love dealing with 12volt wiring and decided to try my take on a homemade torque converter lock up switch. Nothing fancy, just a switch that forces lock and unlock and that is it.

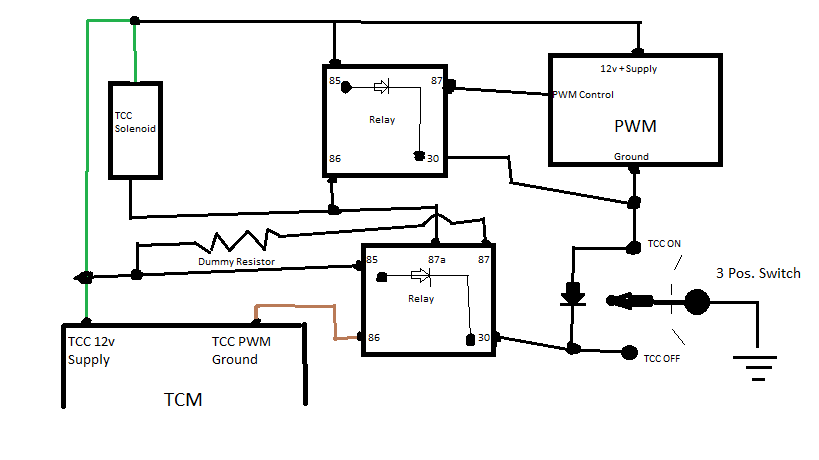

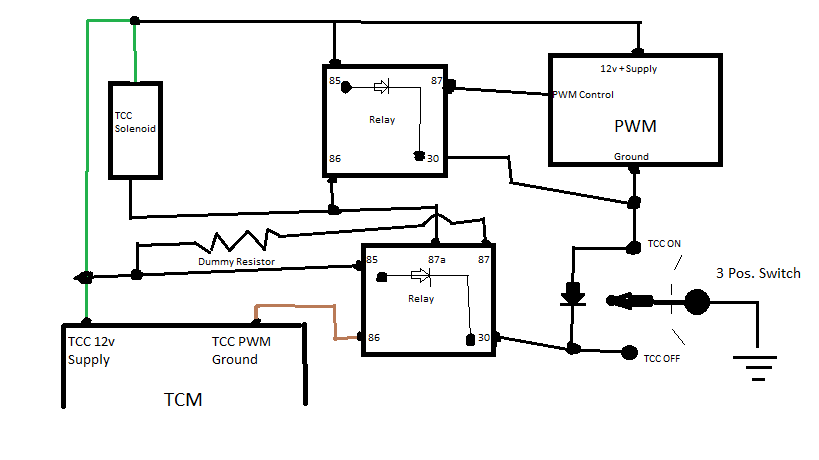

Pardon the primitive drawing but this is what I was coming up with based on my little knowledge of how the Allison converter clutch circuit works. In the drawing I have kind of generalized what the PWM Module represents as I feel that will be a more researched, trial-and-error sort of setup later on if this does work. Just trying to find a different solution for those more 'do-it-your-self' types that don't want to buy a lockup box.

In theory I believe this setup should not set any TCC CIRCUIT codes, however the use of basic mechanical relays may not be of best nature. I also have no idea what the TCM will think in regards to the codes "P0741-Torque Converter Stuck off" and "P0742-Torque Converter Stuck On".

I would love to hear any critisizm on this from everyone. Let me know if I'm crazy or if I have overlooked something, or if I should actually take it to the next level and try this out.

Note: I am in no way trying to step on anyone's toes that create these lockup boxes for the Dmax community nor did I 'reverse engineer' any persons product. This is just a theory that has popped in my head that I would like to share.

Pardon the primitive drawing but this is what I was coming up with based on my little knowledge of how the Allison converter clutch circuit works. In the drawing I have kind of generalized what the PWM Module represents as I feel that will be a more researched, trial-and-error sort of setup later on if this does work. Just trying to find a different solution for those more 'do-it-your-self' types that don't want to buy a lockup box.

In theory I believe this setup should not set any TCC CIRCUIT codes, however the use of basic mechanical relays may not be of best nature. I also have no idea what the TCM will think in regards to the codes "P0741-Torque Converter Stuck off" and "P0742-Torque Converter Stuck On".

I would love to hear any critisizm on this from everyone. Let me know if I'm crazy or if I have overlooked something, or if I should actually take it to the next level and try this out.

Note: I am in no way trying to step on anyone's toes that create these lockup boxes for the Dmax community nor did I 'reverse engineer' any persons product. This is just a theory that has popped in my head that I would like to share.